Rotary cultivator

A rotary tiller and knife shaft technology is applied in the field of rotary tillers to avoid misoperation and loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

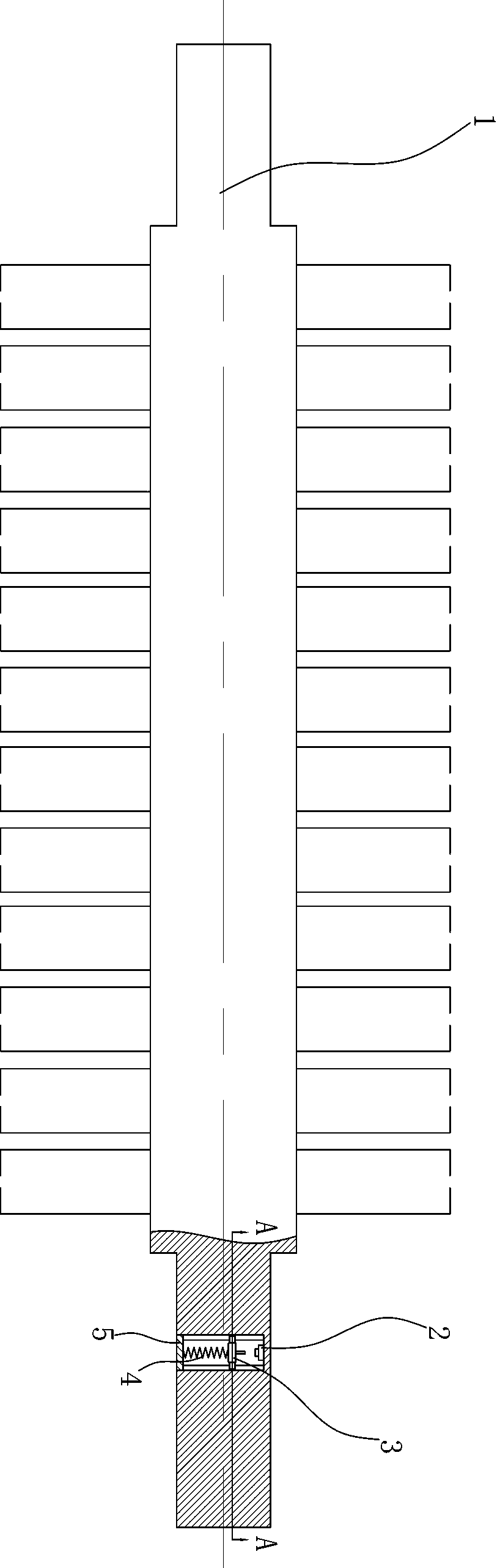

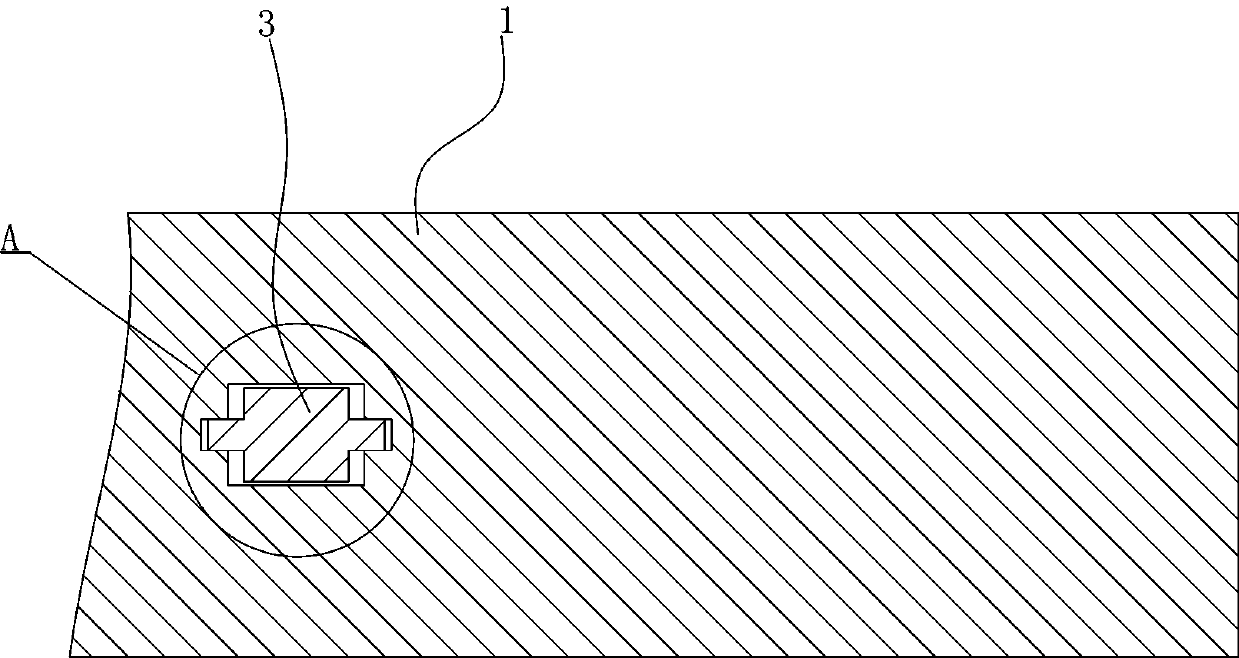

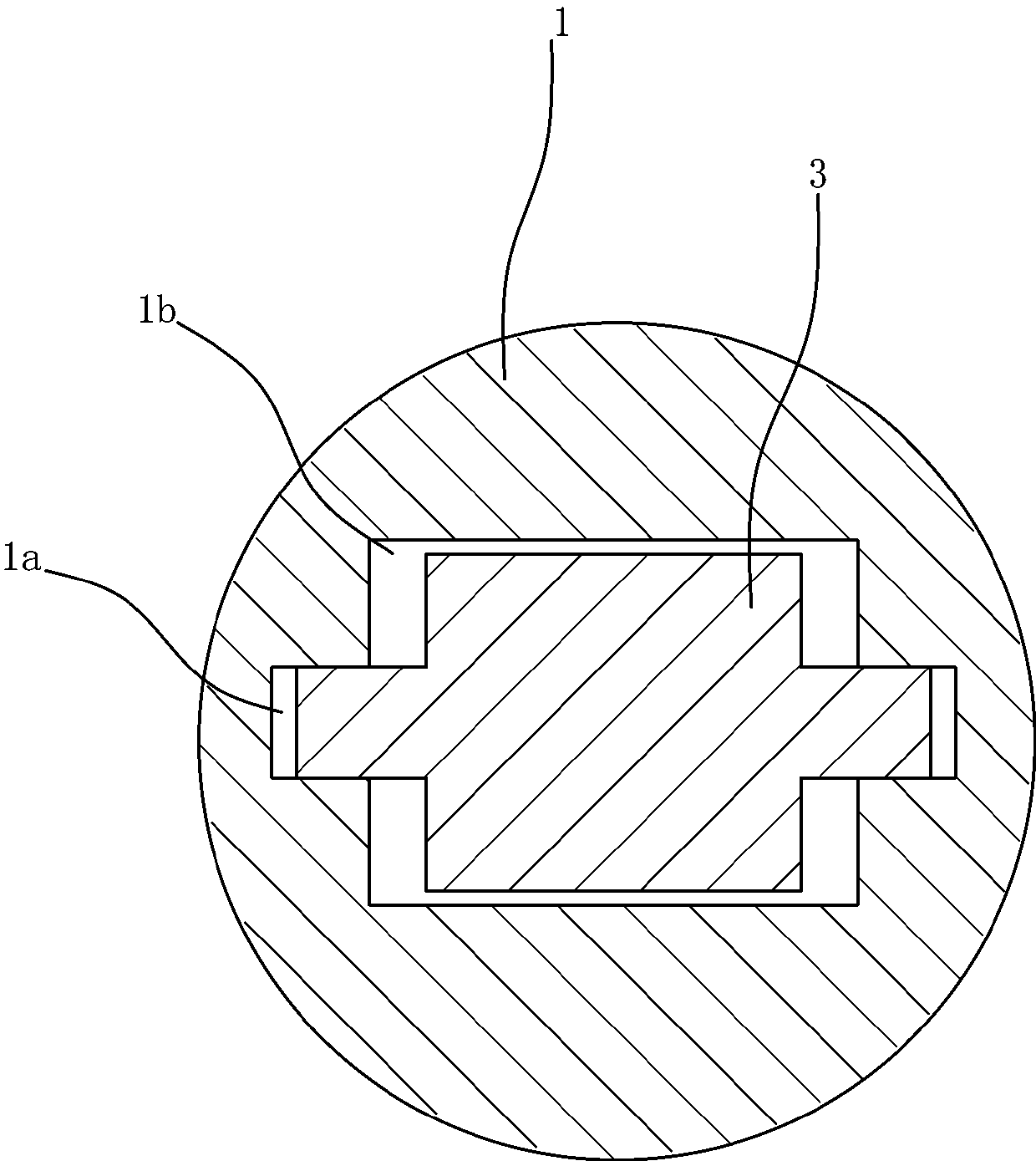

[0011] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings. A rotary tiller, comprising a cutter shaft 1, the cutter shaft 1 is provided with a rectangular blind hole 1b, the axis of the blind hole 1b coincides with the radial direction of the cutter shaft 1, and the two opposite sides of the blind hole 1b A chute 1a with a rectangular cross section is provided on the wall. A switch 2 is provided at the center of the bottom surface of the blind hole 1b. A push rod 3 is also arranged in the blind hole 1b, and the push rod 3 is composed of a base 3b, a push rod 3a and a slider 3c. The base 3b is a rectangular block and matches the blind hole 1b. A cylindrical push rod 3a is provided at the center of the top surface of the base 3b, and a cylindrical push rod 3a is provided at the center of the left and right side walls of the base 3b. A slide block 3c, the slide block 3c is matched with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com