Filter bags for vacuum cleaners and method for determining the surface area of vacuum cleaner filter bags directly exposed to air flow

A vacuum cleaner and filter bag technology, applied in the field of filter bags, can solve the problems of filter material damage, increase in pressure drop of vacuum cleaner filter bags, and decrease in overall performance of filter bags, and achieve the effect of increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

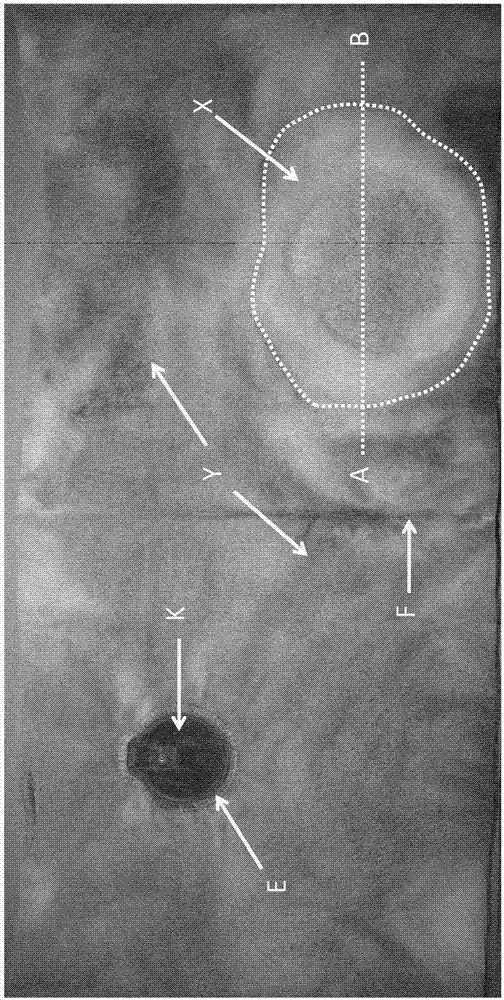

[0086] exist figure 1 In , a vacuum cleaner filter bag implementing the method according to the invention for determining a surface directly exposed to an air flow is shown. Thus, the vacuum cleaner filter bag is a flat bag with welded edges. exist figure 1 , a vacuum cleaner filter bag is shown cut open, whereby the peripheral weld seam previously present at the edge is cut away on three sides, leaving only one weld seam (fold line F). Therefore, the left and right sides shown in the figure represent the front side or the back side of the filter bag. The front side has an inlet opening E with a sealing plate K via which an inlet connection of the vacuum cleaner can be introduced into the vacuum cleaner filter bag. therefore, figure 1 The right hand side shown in (to the right of fold line F) represents the back side of the vacuum cleaner filter bag. exist figure 1 , a view of the inside of a vacuum cleaner filter bag (ie, the inflow side of the filter material) is shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com