rice transplanter

A rice transplanter and planting technology, applied in transplanting machinery, agriculture, applications, etc., can solve the problems of unstable rotation of the drive system, phase deviation of acceleration and deceleration, and increase in rotation variation, so as to prevent poor planting and improve the phase. Variation of , the effect of suppressing rotation fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

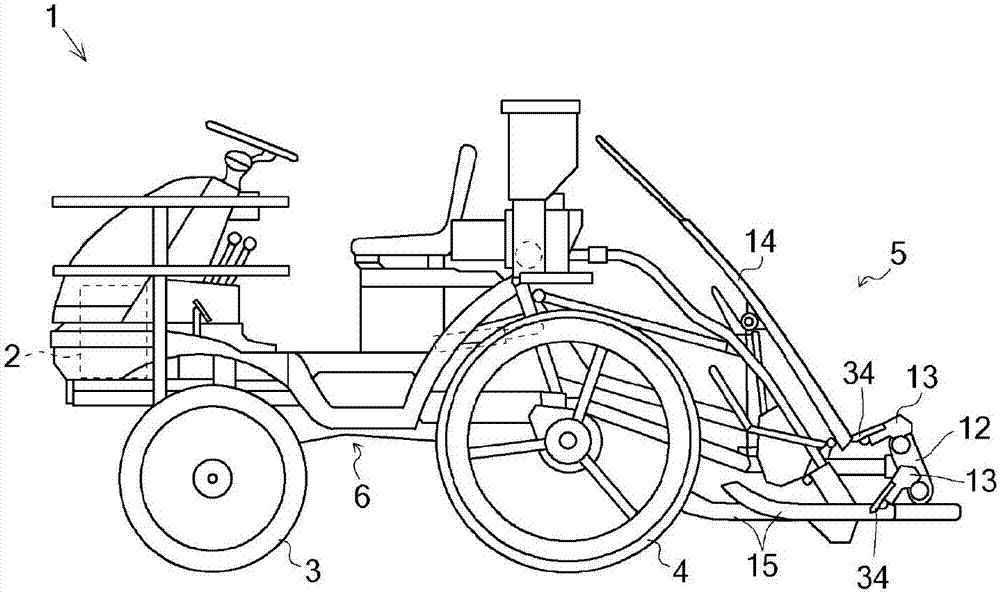

[0033] The rice transplanter 1 is demonstrated with reference to drawings.

[0034] The rice transplanter 1 performs the planting operation by the planting part 5 while driving the front wheel 3 and the rear wheel 4 to travel by the power of the engine 2 . The power from the engine 2 is transmitted to the front wheel 3 and the rear wheel 4 via the transmission case 6, and is transmitted to the planting part 5 via the transmission case 6 and the plant spacing changing device 9, respectively.

[0035] The planting part 5 is provided with the planting center box 10 , the planting bevel gear box 11 , the rotation box 12 , the planting arm 13 , the seedling platform 14 , and the plurality of floating boats 15 .

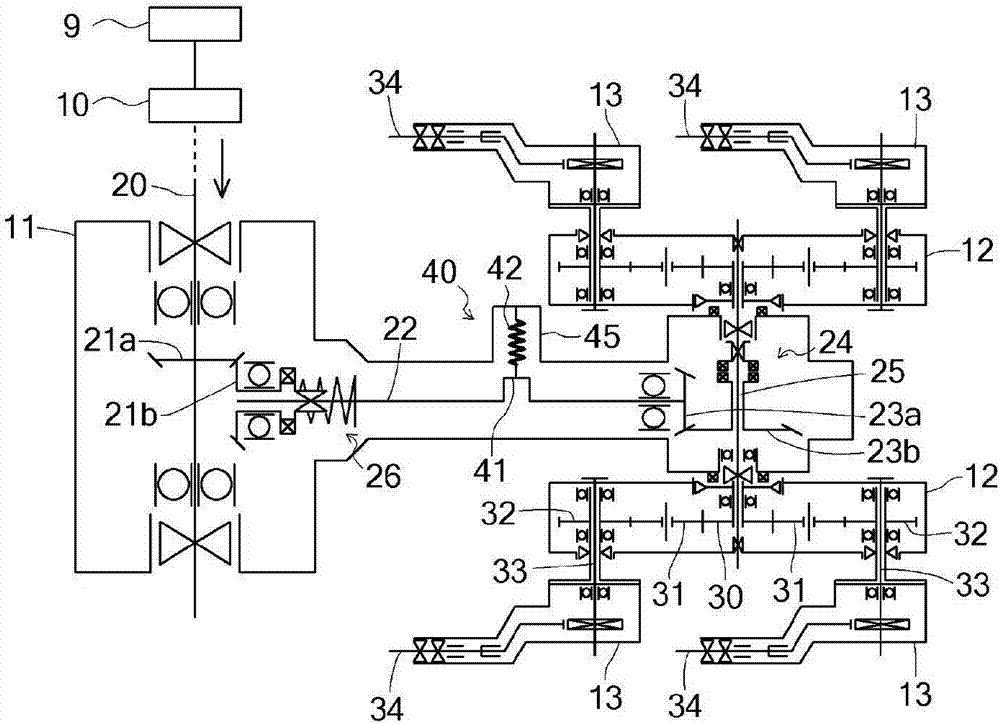

[0036] figure 2 It is a transmission system diagram concerning the planting drive of the planting part 5. figure 2 Although one planting unit is shown, other planting units are configured in the same manner.

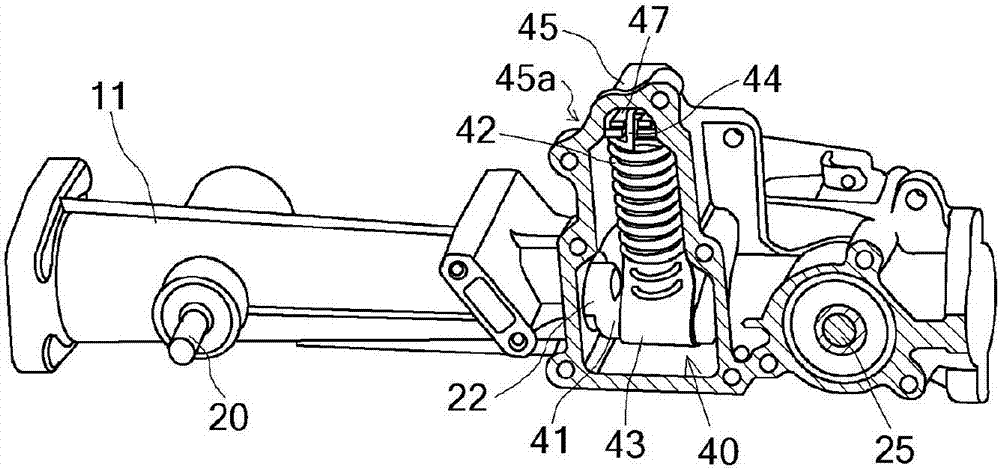

[0037] The planting horizontal shaft 20 branched from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com