Boost power supply controller for carrying spacecraft

A technology of boost power supply and controller, applied in load supply circuits, collectors, electric vehicles, etc., can solve the problems of inability to meet the requirements of satellite loads on busbar quality, large voltage fluctuation range, etc., and achieve high reliability and universality. The effect of good performance and low output ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

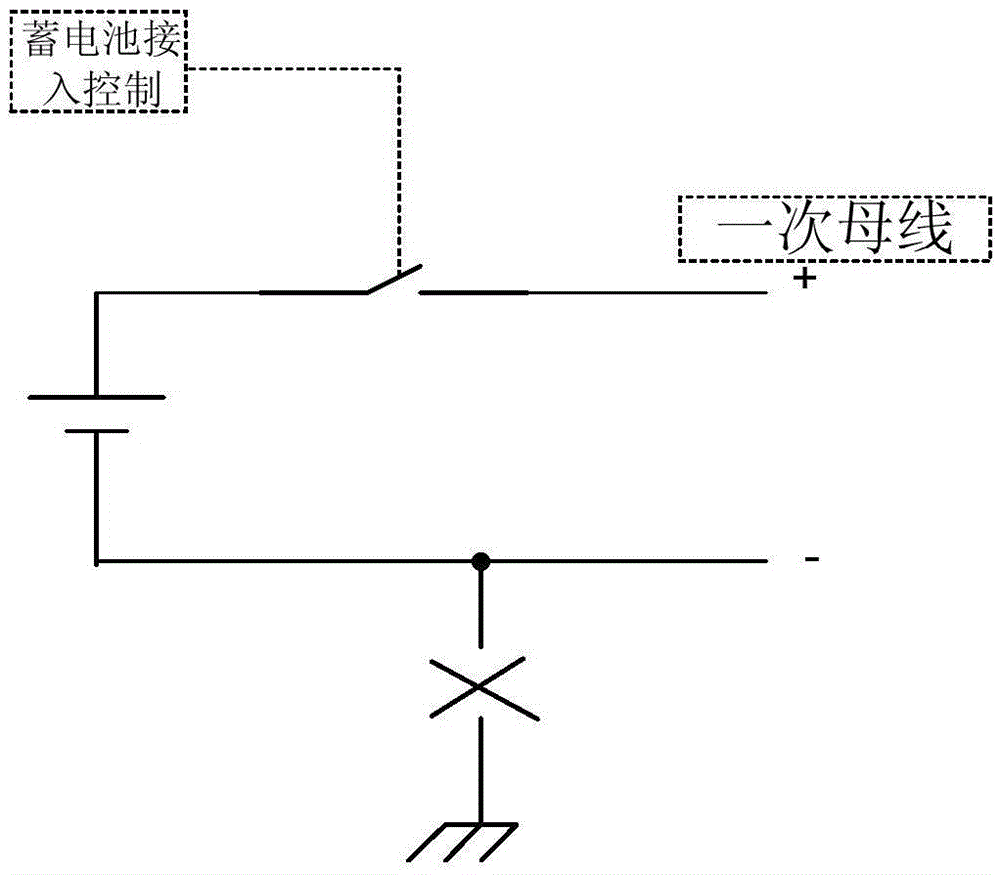

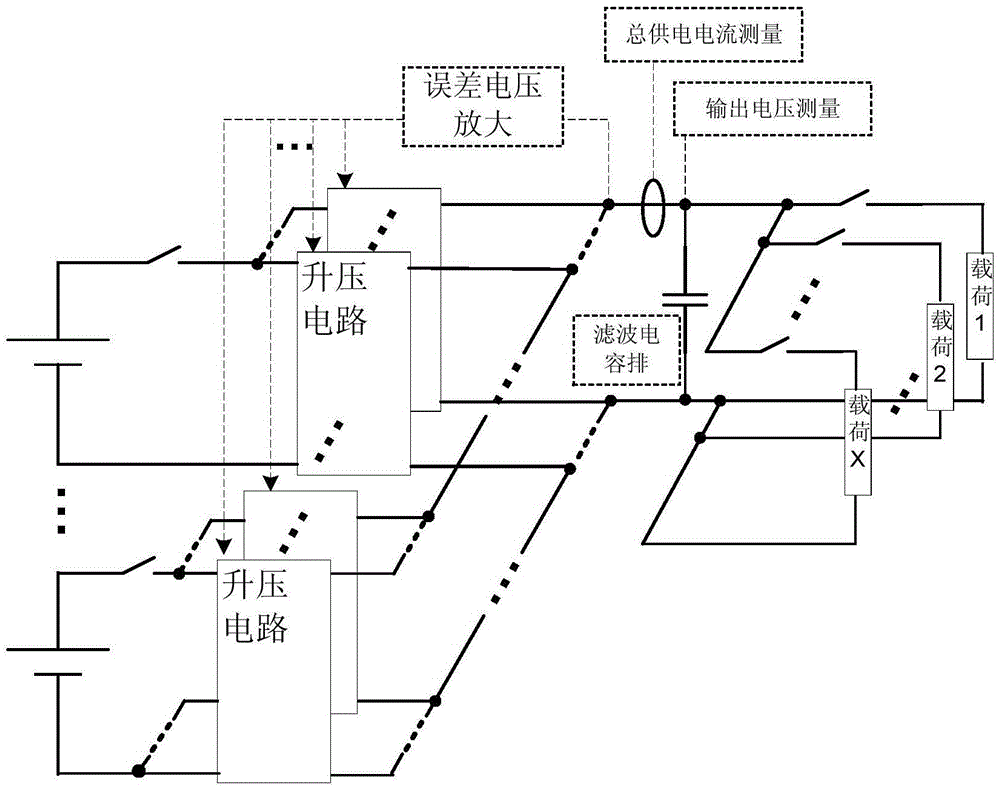

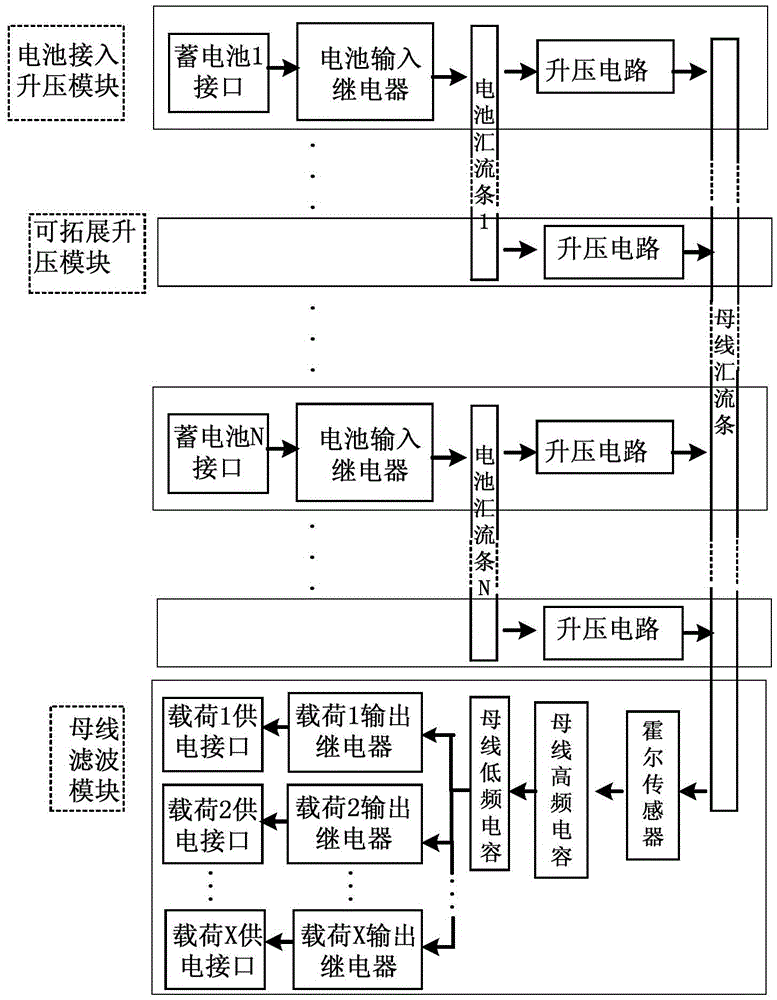

[0030] see Figure 1 to Figure 7 , a booster power supply controller for a carrier spacecraft, comprising:

[0031] M non-isolated boost circuits for converting the output voltages of N batteries into required voltages; where M is a natural number greater than 1; the positive output terminal of each battery is connected to a battery bus bar through a battery input relay , each battery bus bar is electrically connected to the input positive terminal of at least one booster circuit; the power output positive terminal of each booster circuit is electrically connected to the same bus bar; all booster circuit input and output power negative terminals are connected to A negative bus bar is electrically connected.

[0032] A bus filter unit for fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com