Preparation method of NixV-LDH/C composite material

A carbon composite material and hydrotalcite technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of poor stability and low specific capacity, and achieve the advantages of simple process, improved specific capacity and cycle stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) In an ice-water bath, add 0.2 g of acetylene black (AB) into a beaker containing 15 mL of concentrated sulfuric acid, and slowly add 2 g of potassium permanganate into the above mixture under stirring conditions. After the addition, the mixture was transferred to a 150mL round-bottomed flask, heated to 40°C, stirred in a water bath for 1 hour, cooled to room temperature, poured into deionized water for dilution, and then centrifuged at 8500 rpm to remove the solution. Use 500mL of deionized water and ethanol to wash the lower black precipitate obtained by centrifugation until the pH of the filtrate is 6.5-7, and dry it at 60°C for 10 hours to obtain oxyacetylene black (ABO-1) with a low degree of oxidation.

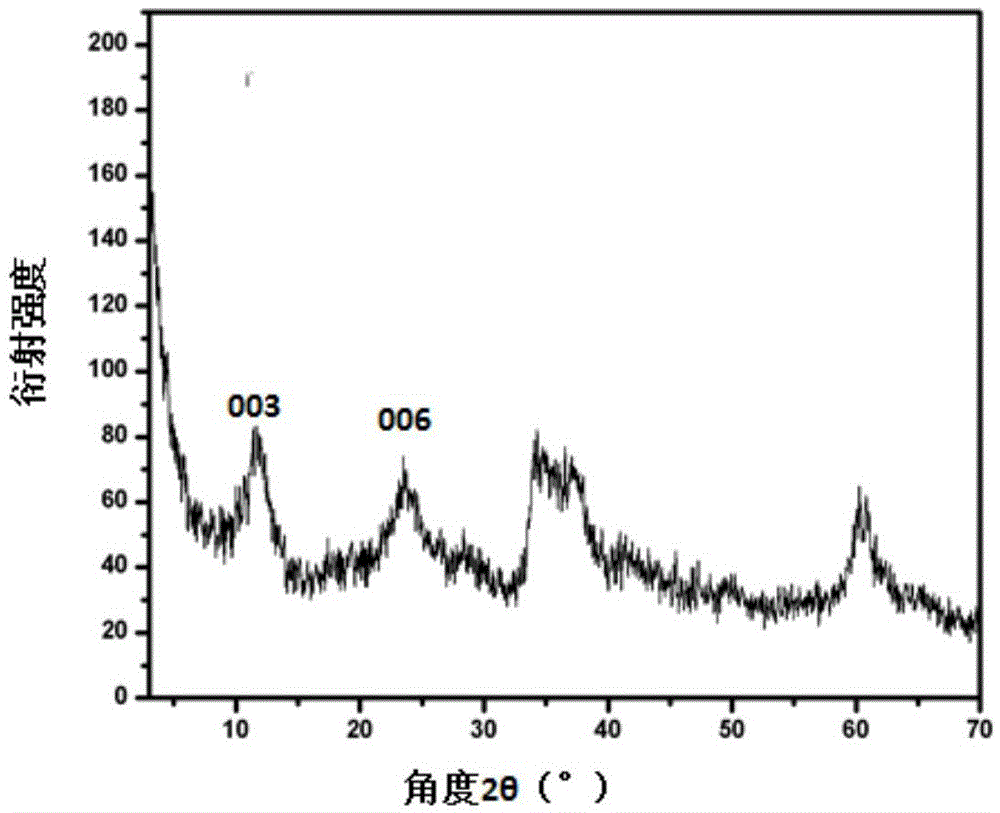

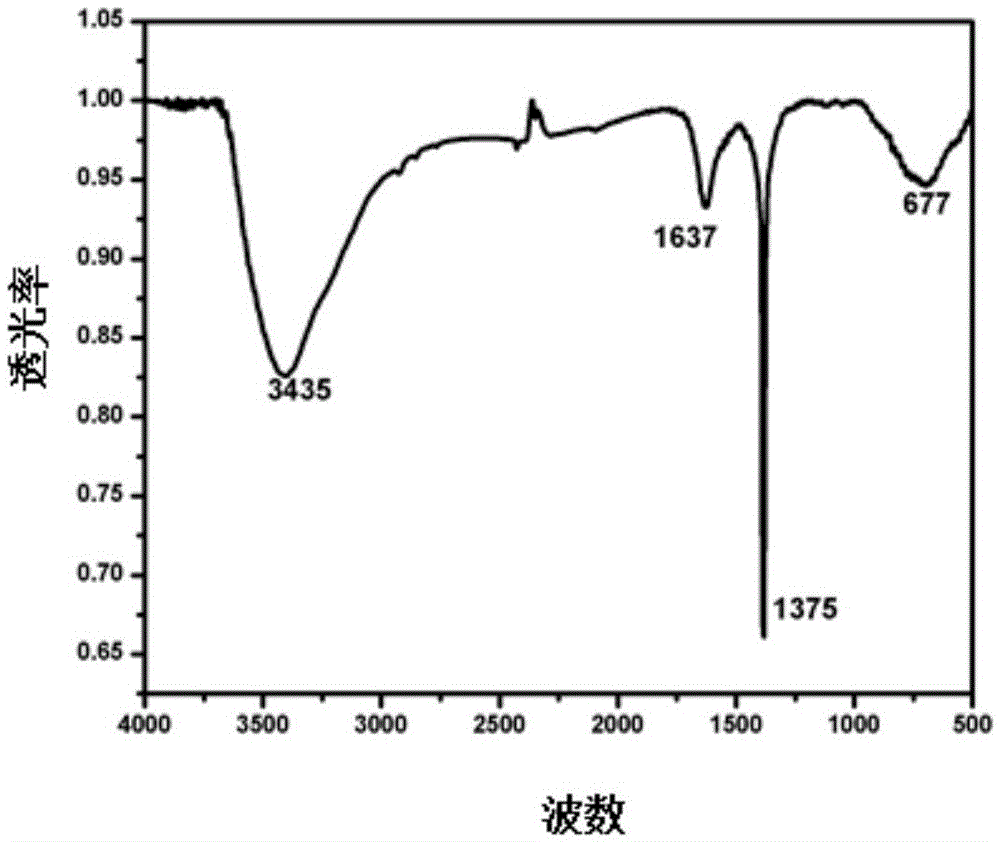

[0023] (2) 2.5mmol of NiCl 2 ·6H 2 O, 1.25 mmol VCl 3 Dissolve in 40mL of deoxygenated deionized water, then add 0.3g of acetylene black oxide to the above mixed salt solution, ultrasonicate for 40-60min under a nitrogen protective atmosphere, and then transf...

Embodiment 2

[0025](1) In an ice-water bath, add 0.2 g of acetylene black (AB) into a beaker containing 15 mL of concentrated sulfuric acid, and slowly add 2 g of potassium permanganate into the above mixture under stirring conditions. After the addition, the mixture was transferred to a 150mL round-bottomed flask, heated to 40°C, stirred in a water bath for 3 hours, cooled to room temperature, poured into deionized water for dilution, and then centrifuged at 8500 rpm to remove the solution. Use 500mL of deionized water and ethanol to wash the lower black precipitate obtained by centrifugation until the pH of the filtrate is 6.5-7, and dry it at 60°C for 10 hours to obtain acetylene black oxide (ABO-2) with a higher degree of oxidation.

[0026] (2) 2.5mmol of NiCl 2 ·6H 2 O, 1.25 mmol VCl 3 Dissolve in 40mL of deoxygenated deionized water, then add 0.3g of acetylene black oxide to the above mixed salt solution, ultrasonicate for 40-60min under a nitrogen atmosphere, and then transfer to...

Embodiment 3

[0028] (1) In an ice-water bath, add 0.2 g of acetylene black (AB) into a beaker containing 15 mL of concentrated sulfuric acid, and slowly add 2 g of potassium permanganate into the above mixture under stirring conditions. After the addition is complete, transfer the mixed solution to a 150mL round-bottomed flask, raise the temperature to 90°C, stir in a water bath for 1h, cool to room temperature, pour into deionized water for dilution, and then centrifuge at 8500 rpm to remove the solution, and then sequentially Use 500ml of deionized water and ethanol to wash the lower layer of black precipitate obtained by centrifugation until the pH value of the filtrate is 6.5-7, and dry it with air at 60°C for 10 hours to obtain oxyacetylene black (ABO) with a higher degree of oxidation under different temperature conditions. -3).

[0029] (2) 2.5mmol of NiCl 2 ·6H 2 O, 1.25 mmol VCl 3 Dissolve in 40mL of deoxygenated deionized water, then add 0.3g of acetylene black oxide to the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com