SH guided wave detection method for interfacial state of bonded structure

A detection method and interface technology, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve the problems of undiscovered SH wave propagation characteristics, lack of theoretical support, and lack of form Discriminatory Theoretical Research and Other Issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

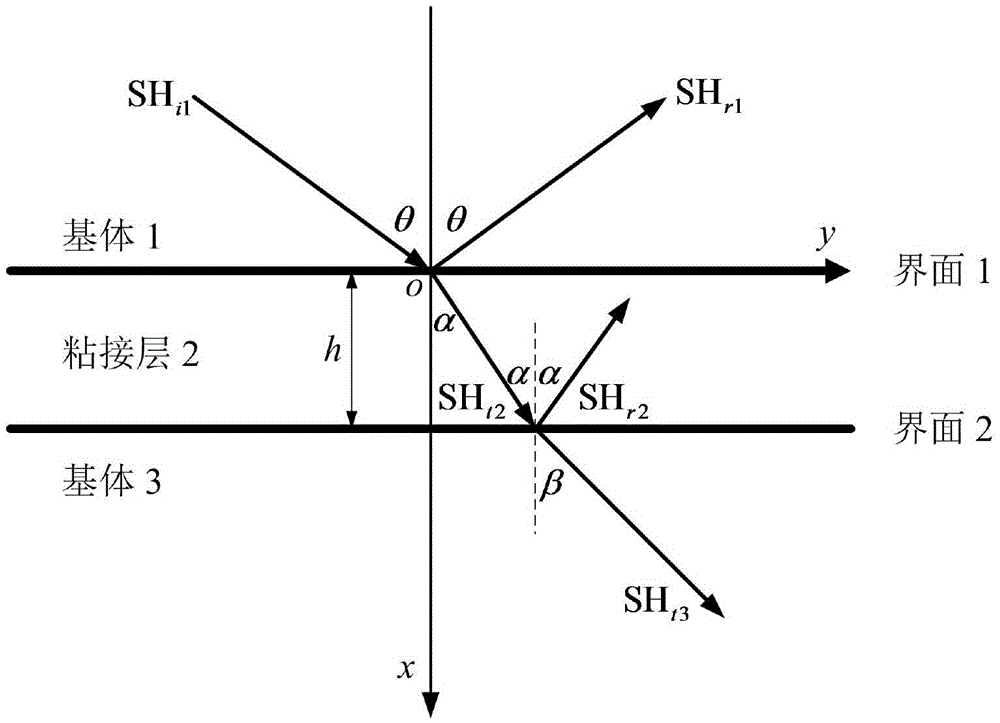

[0054] This implementation case includes the following steps:

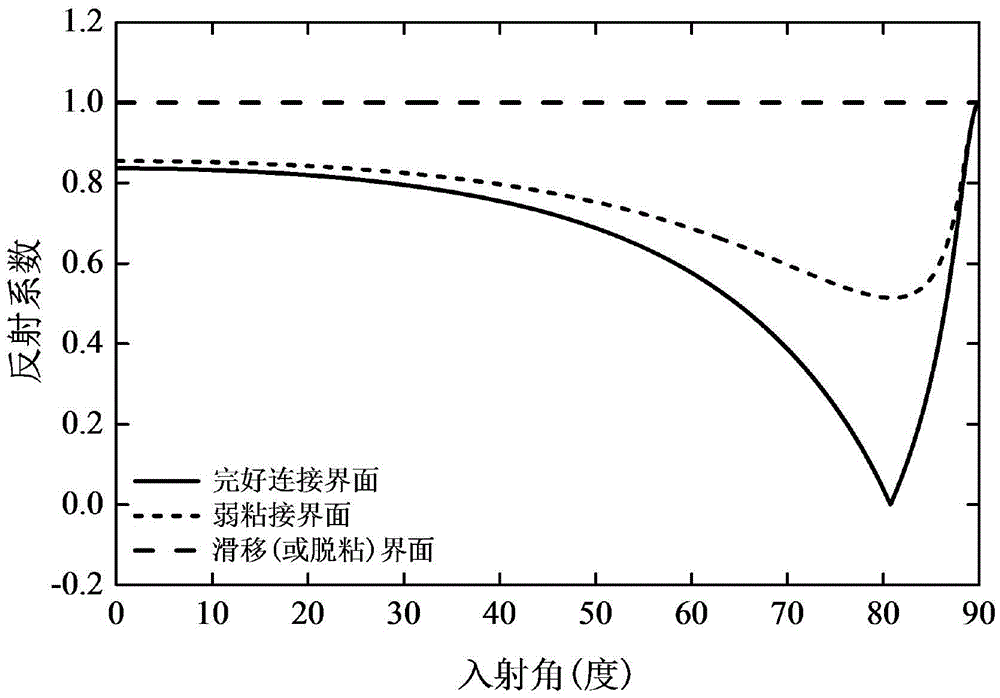

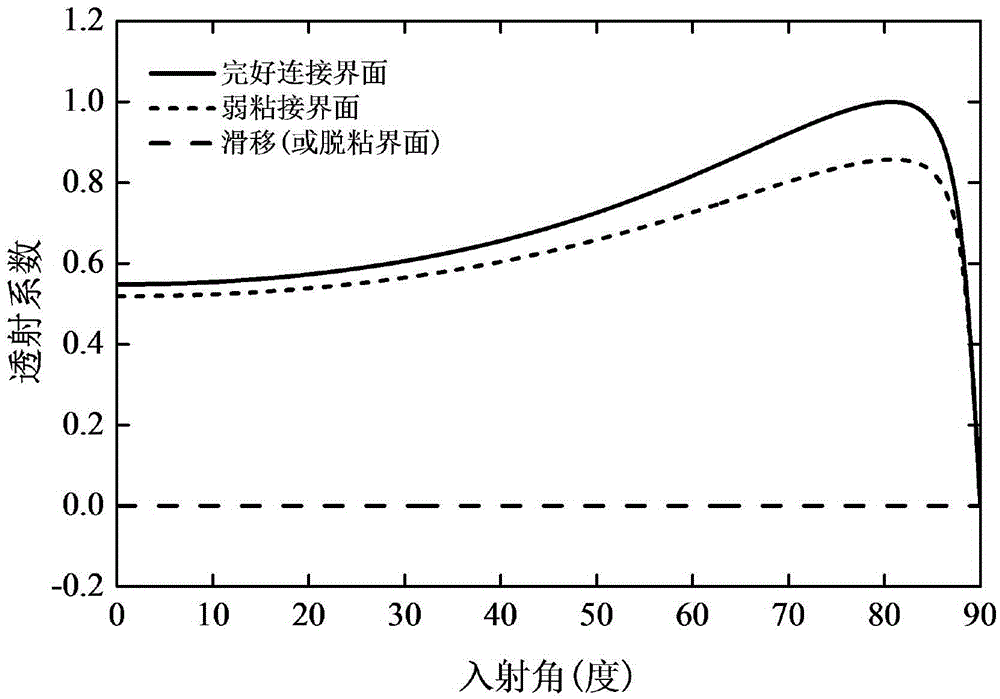

[0055] 1) Suppose the incident frequency f of the SH wave is 1MHz, the thickness h of the adhesive layer is 0.1mm, K T (2) =3×10 16 (N / m 3 ), these three parameters are substituted into the two equations of the expression (10) of step 2.0. Order K T (1) =3×10 16 (N / m 3 ) indicates that the interface 1 of the bonded structure is a complete connection interface; let K T (1) =7×10 12 (N / m 3 ) indicates that the interface 1 of the bonding structure is a weakly bonding interface; let K T (1) →0 indicates that interface 1 of the bonded structure is a slip (or debonding) interface. The tangential stiffness coefficient (K T (1) ) respectively and the tangential stiffness coefficient (K T (2) ) combined (eg K T (2) =3×10 16 (N / m 3 ) and K T (1) =7×10 12 (N / m 3 ) combination indicates that interface 2 of the bonded structure is a well-connected interface but interface 1 is a weakly bonded interface,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| P-wave velocity | aaaaa | aaaaa |

| S-wave velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com