Deep sea high pressure environment simulation device capable of reducing requirement for wall thickness and material strength

A high-pressure environment and simulation device technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, pressure vessels, etc., can solve the problems of not having high-strength materials, so as to improve the strength of the cylinder wall and reduce the requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

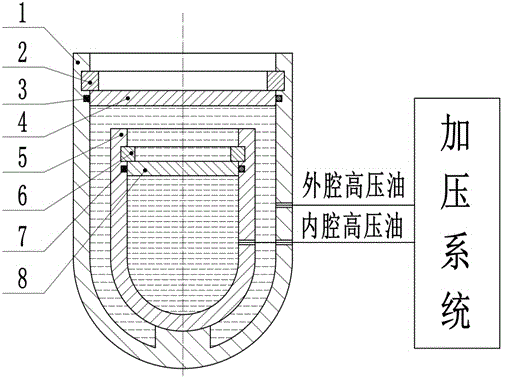

[0012] Such as figure 1 As shown, the present invention consists of an outer cylinder 1, an outer shear block 2, an outer sealing ring 3, an outer flat cover 4, an inner cylinder 5, an inner shear block 6, an inner sealing ring 7 and an inner flat cover 8.

[0013] The outer flat cover 4 is installed in the outer cylinder 1, and the outer shear block 2 is installed in the slot of the outer cylinder 1, together with the outer sealing ring 3, the sealing between the outer flat cover 4 and the outer cylinder 1 is guaranteed; the outer flat cover 4 and the outer Cylinder 1 forms an external high-pressure chamber, and the pressure control of the external high-pressure chamber is realized by the high-pressure oil in the external cavity of the pressurization system; the inner cylinder 5 is installed in the outer high-pressure chamber formed by the outer flat cover 4 and the outer cylinder 1; the inner flat cover 8 is installed on the In the inner cylinder 5, the inner shear block 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com