Energy-saving and environment-friendly type combustion system of gas wall-hanging stove

A gas wall-hung boiler and combustion system technology, which is applied to gas fuel burners, burners, and combustion methods, can solve the problems of inability to burn gas instantly, large vibration of gas wall-hung boilers, and large hydrogen and methane emissions. Smooth smoke exhaust, low cost, and large air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

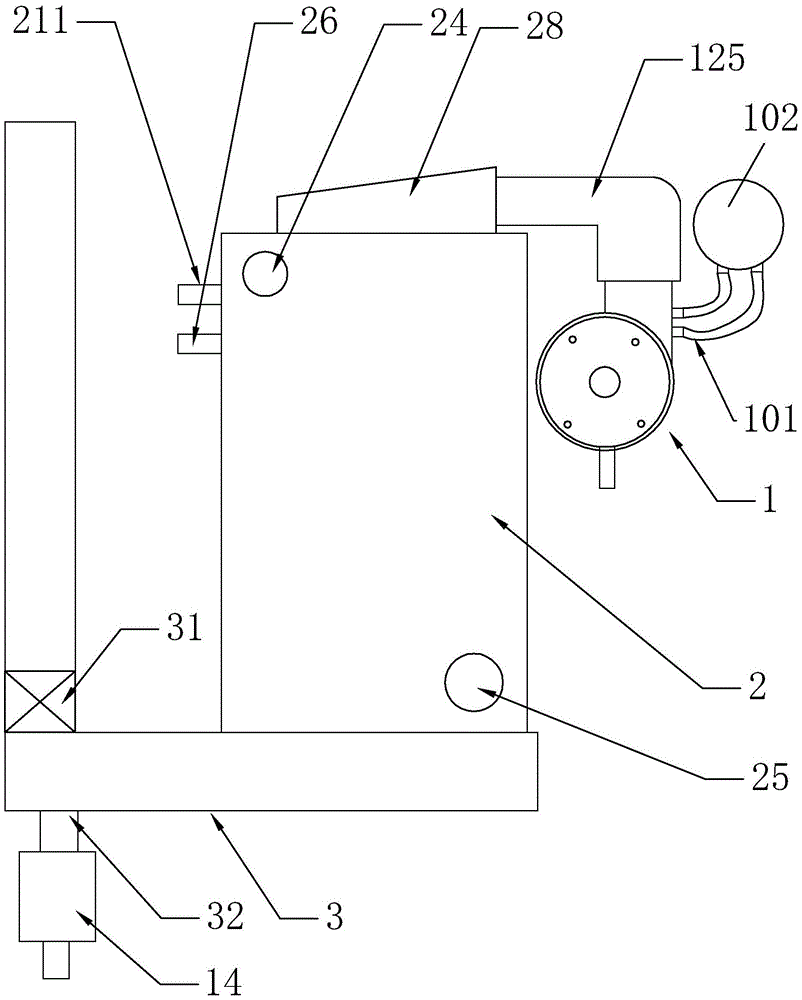

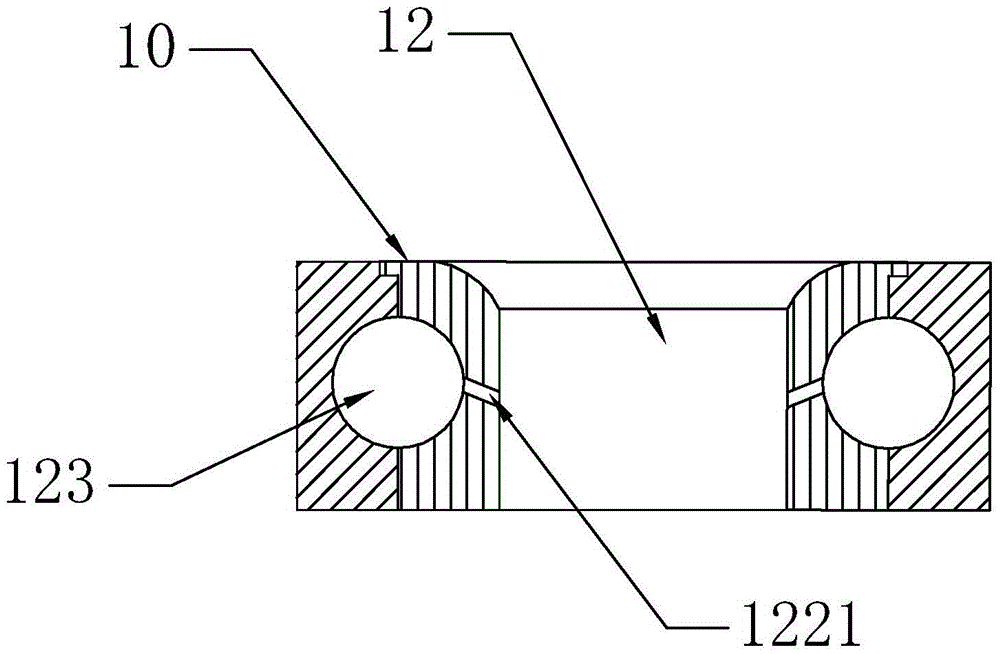

[0037] When the combustion heat exchanger 2 is about to burn and heat water, the water valve is opened so that the water flow enters from the water inlet 27, the exhaust fan 32 works, the blower fan 11 starts, and the gas enters the gas circulation ring hole 123 from the gas inlet hole 121, and passes through the gas injection hole 121. The hole 1221 sprays out to the through hole 12, and is inhaled into the inner cavity of the fan through the fan 11. At the same time, the outside wind is sucked into the inner cavity of the fan through the air inlet hole 1241 and the air induction pipe 1242, and the air and gas are mixed by the agitation of the fan 11. Mixing, send the mixed gas into the combustion chamber 21 through the short gas connection pipe 125, ignite and burn through the ignition needle 211 to heat the combustion heat exchanger 2, the burnt fire tail and smoke body go down, pass through the heat exchange channel 22, and then The smoke exhaust port 23 at the bottom disch...

example 2

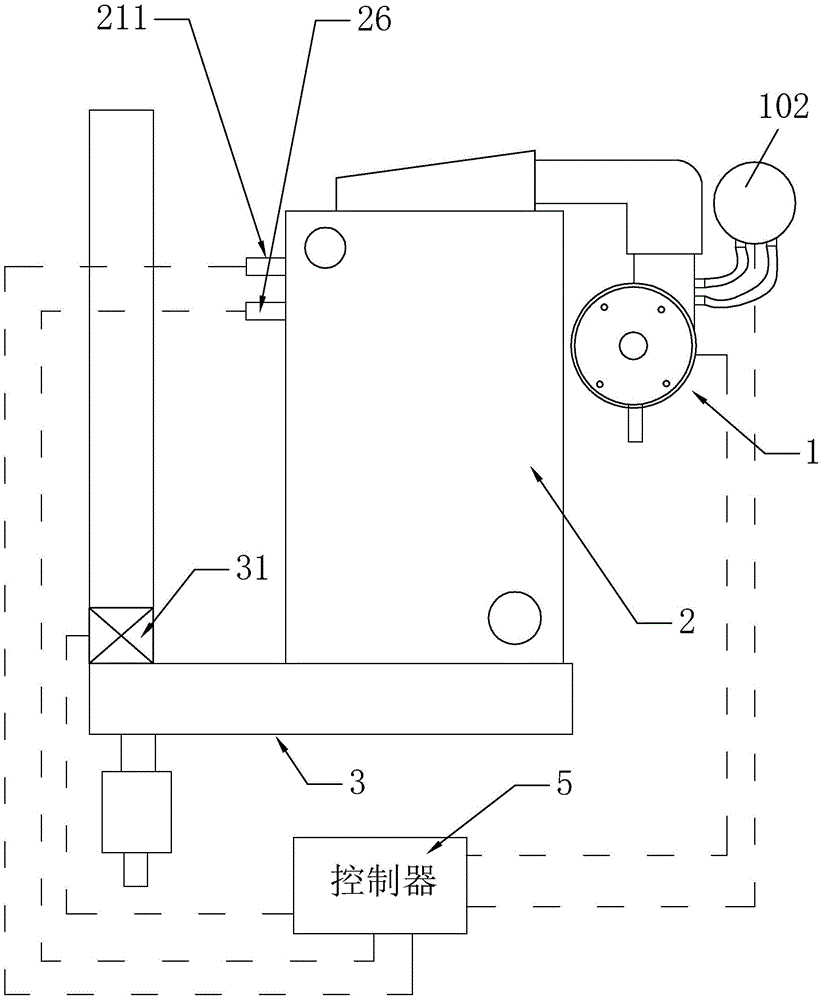

[0039] When the combustion heat exchanger 2 is going to burn and heat water, the water valve is opened so that the water flow enters from the water inlet 27, the wind pressure switch 102 sets the wind pressure value for starting the exhaust fan 31, the blower fan 11 is started, and the gas valve is opened to make the gas flow from the gas The air inlet hole 121 enters the gas circulation ring hole 123, and the gas is ejected to the through hole 12 through the gas injection hole 1221, sucked into the inner cavity of the fan through the fan 11, and also sucks the outside wind through the air inlet hole 1241 and the air duct 1242. In the inner cavity of the blower, the air and gas are mixed by the stirring of the fan 11 wind wheel, and the mixed gas is sent into the combustion chamber 21 through the gas connection short pipe 125, and is ignited and burned by the ignition needle 211 to heat the combustion heat exchanger 2, and the burnt fire tail And the smoke body goes down, passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com