Piston type pressure reducing valve

A piston-type, pressure-reducing valve technology, applied to valve details, safety valves, balance valves, etc., can solve problems such as large outlet pressure fluctuations, high water quality requirements, frequent diaphragm replacement, etc., to achieve small outlet pressure fluctuations, vibration Small, good flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

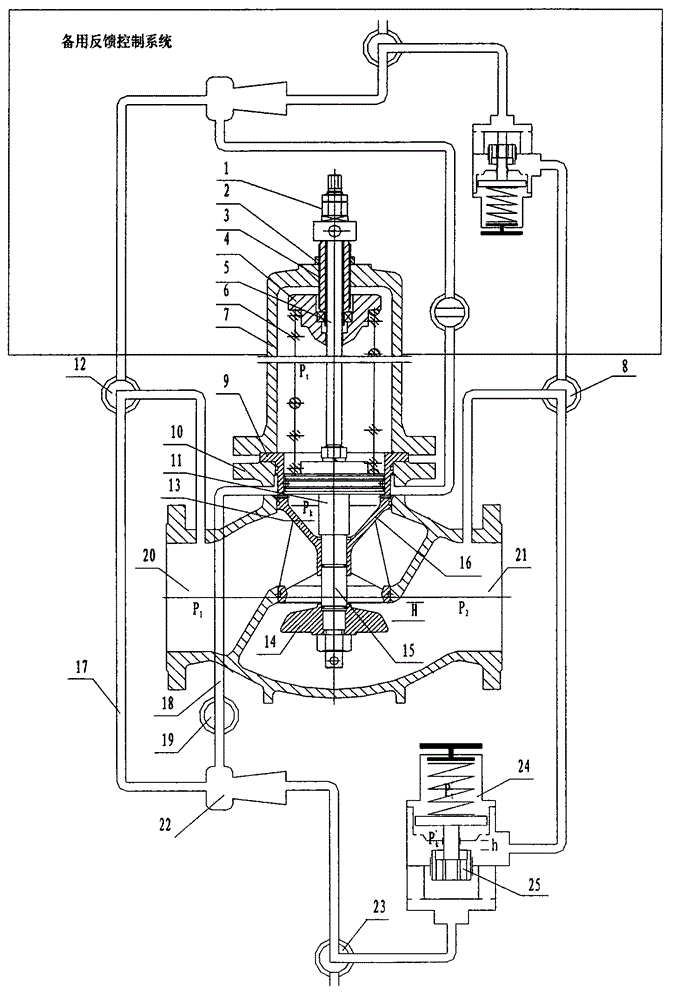

[0011] Such as figure 1 As shown, a piston pressure reducing valve includes a valve body 9 with an inlet and an outlet. The valve body 9 includes a valve cover 7, a main spring 6 located in the valve cover 7, a piston 11, and a piston rod 15. Its characteristics In that: the valve body 9 has two sets of symmetrical feedback control systems, the feedback control system includes a recoil blowdown structure; the center of the valve cover 7 is provided with a safety locking device, the upper part of the valve cover 7 is fixed with the spring seat 4, and the lower part is provided with a piston 11. A cylinder liner valve seat assembly 10 that is sealed with the piston 11 is provided around the piston 11; a main spring 6 that can push the piston 11 downward is provided between the piston 11 and the spring seat 4; The valve seat 16 fixedly connected to the valve cover 7 forms a pressure regulating chamber 13 between the valve seat 16 and the piston 11, and the pressure regulating cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com