A clutch normally closed double gear transmission and its shifting process control method

A technology of double gear and control method, applied in the field of automobile transmission, can solve the problems of low life and high difficulty in clutch control, and achieve the effects of high life, compact structure and improved power assist effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

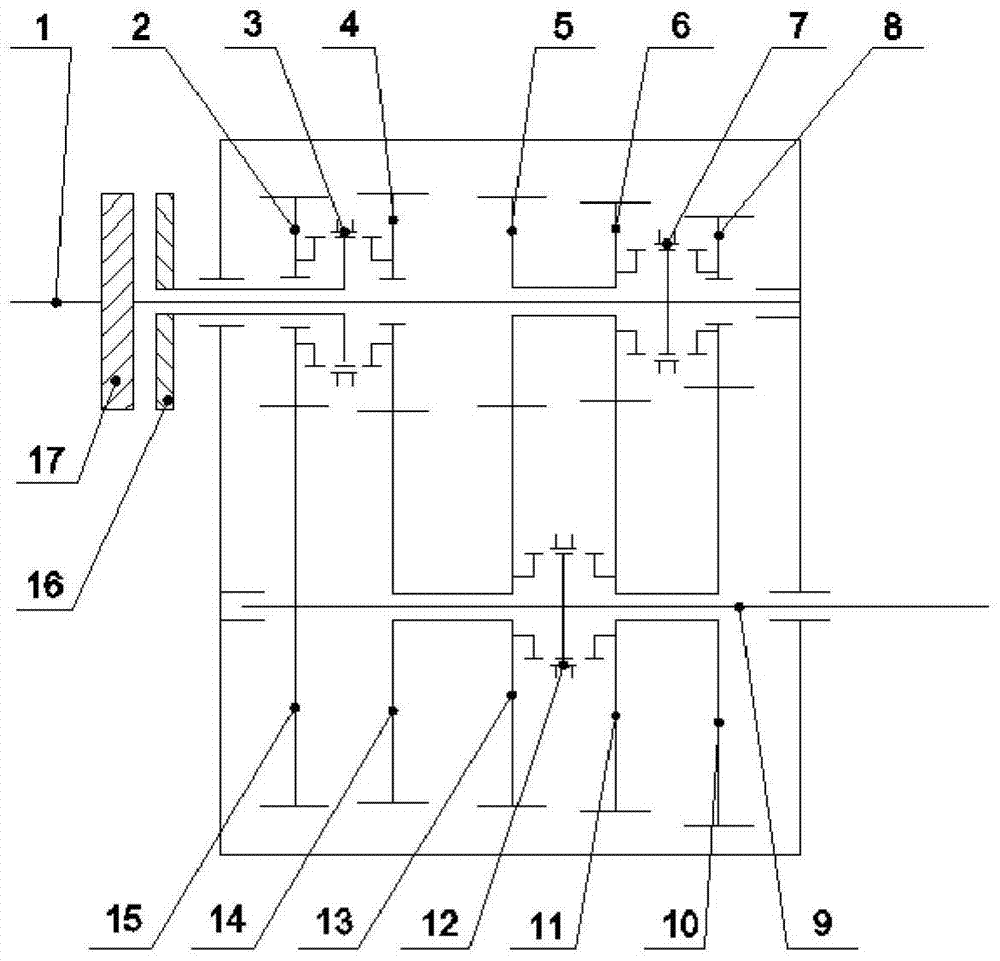

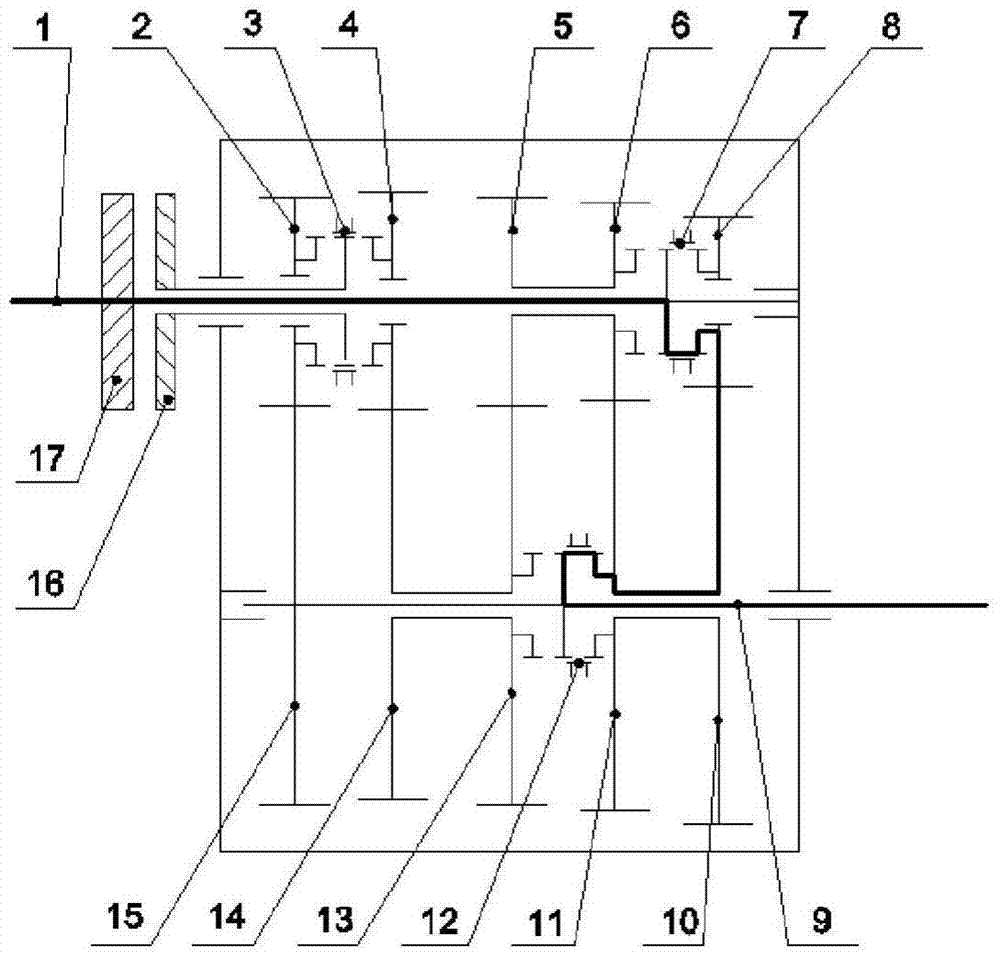

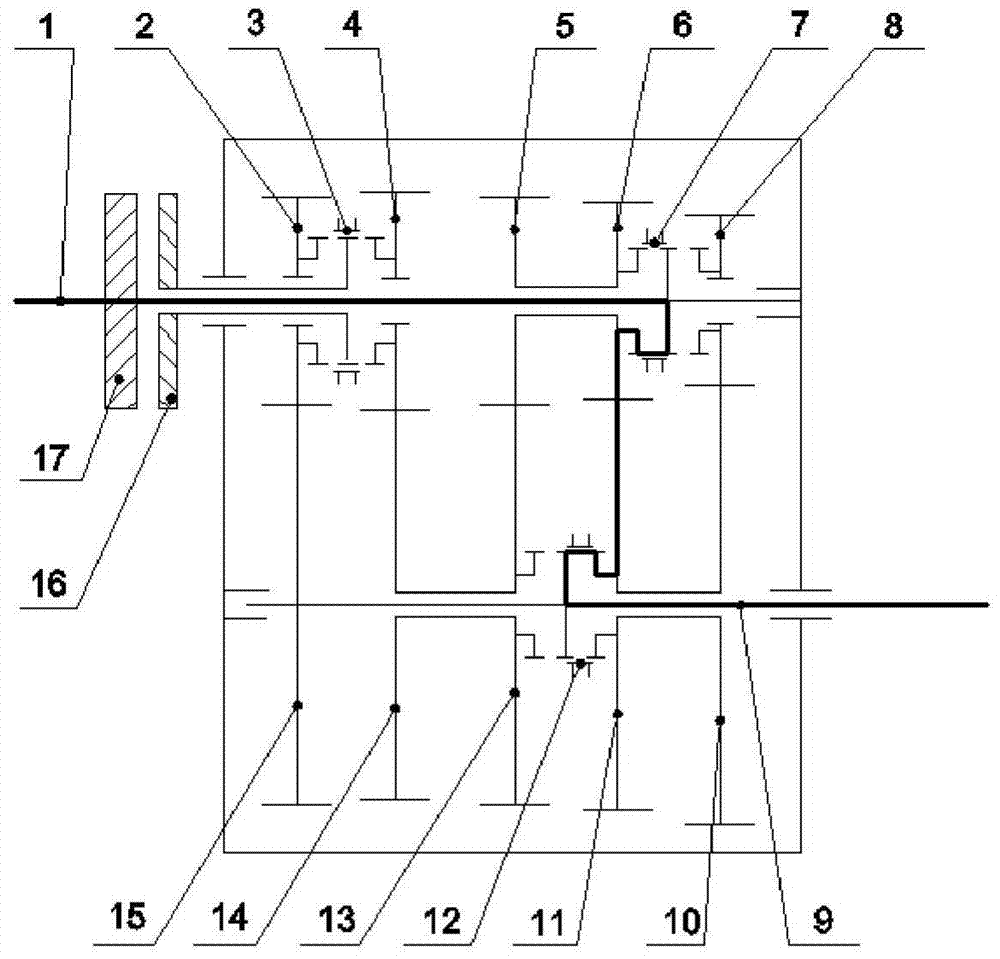

[0039] A clutch normally closed dual gear gearbox includes: input shaft 1, gear I 2, synchronizer I 3, gear II 4, dual gear A (left teeth 5, right teeth 6), synchronizer II 7, gear III 8, output shaft 9 , duplex gear B (10 right teeth, 11 left teeth), synchronizer III 12, duplex gear C (13 right teeth, 14 left teeth), gear Ⅳ 15, clutch friction plate 16 and clutch pressure plate 17, transmission power from Input shaft 1 enters, and output shaft 9 outputs.

[0040] According to the order of clutch friction plate 16, gear I2, gear II4, double gear A (left tooth 5, right tooth 6) and gear III8, they are placed on the input shaft 1 sequentially along the direction of power transmission, and the clutch pressure plate 17 is connected to input axis 1. Duplex gear B (right tooth 10, left tooth 11), duplex gear C (right tooth 13, left tooth 14) is empty sleeve on the output shaft 9, and gear IV 15 is connected on the output shaft 9. Gear III 8 meshes with right tooth 10 of dual gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com