Magnetorheological Elastomer Shock Absorber

A magneto-rheological elastomer and shock absorber technology, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems affecting the application of magnetorheological fluids, easy precipitation, poor stability, etc., to achieve Easy and fast replacement, uniform magnetic field, good vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

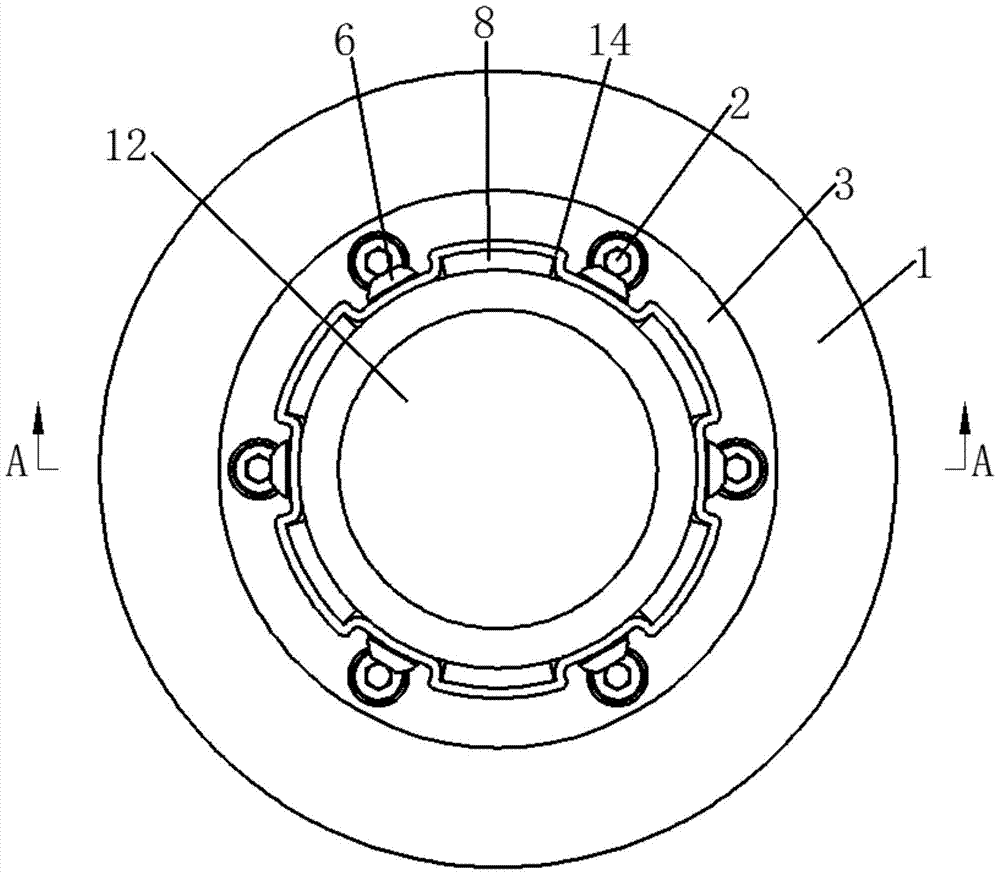

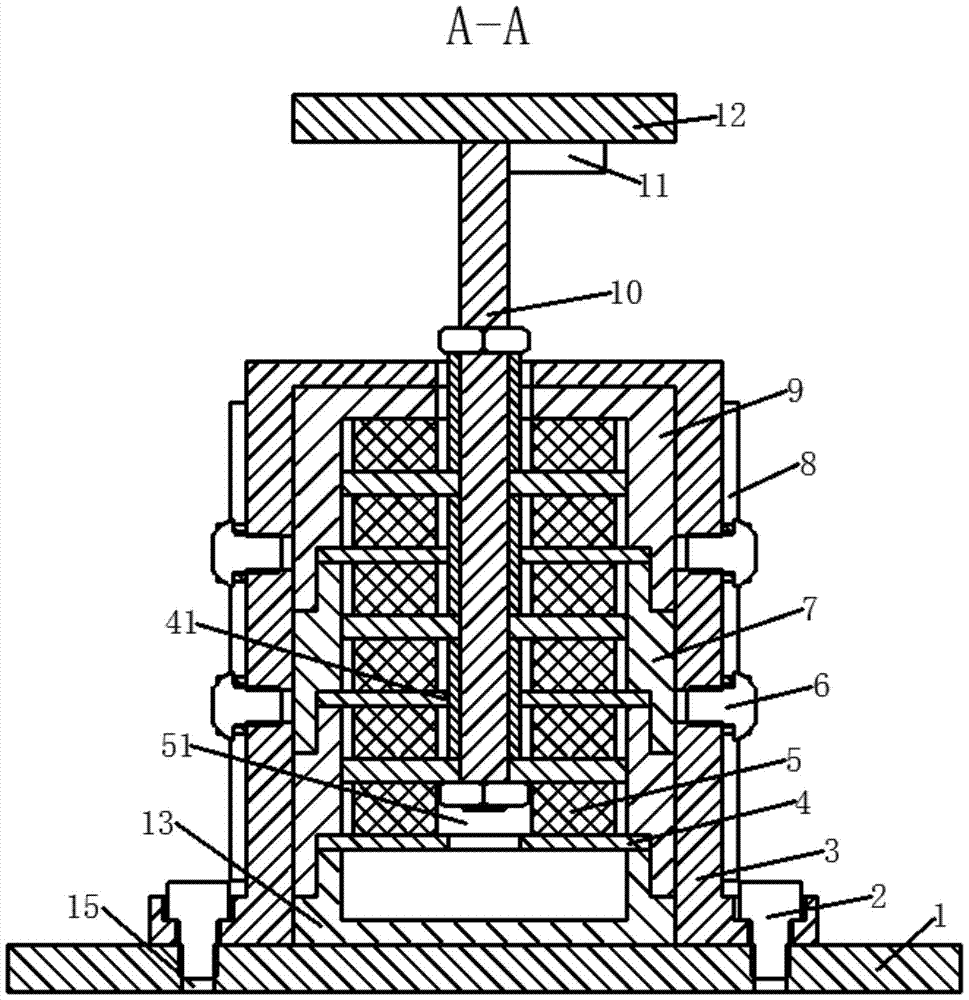

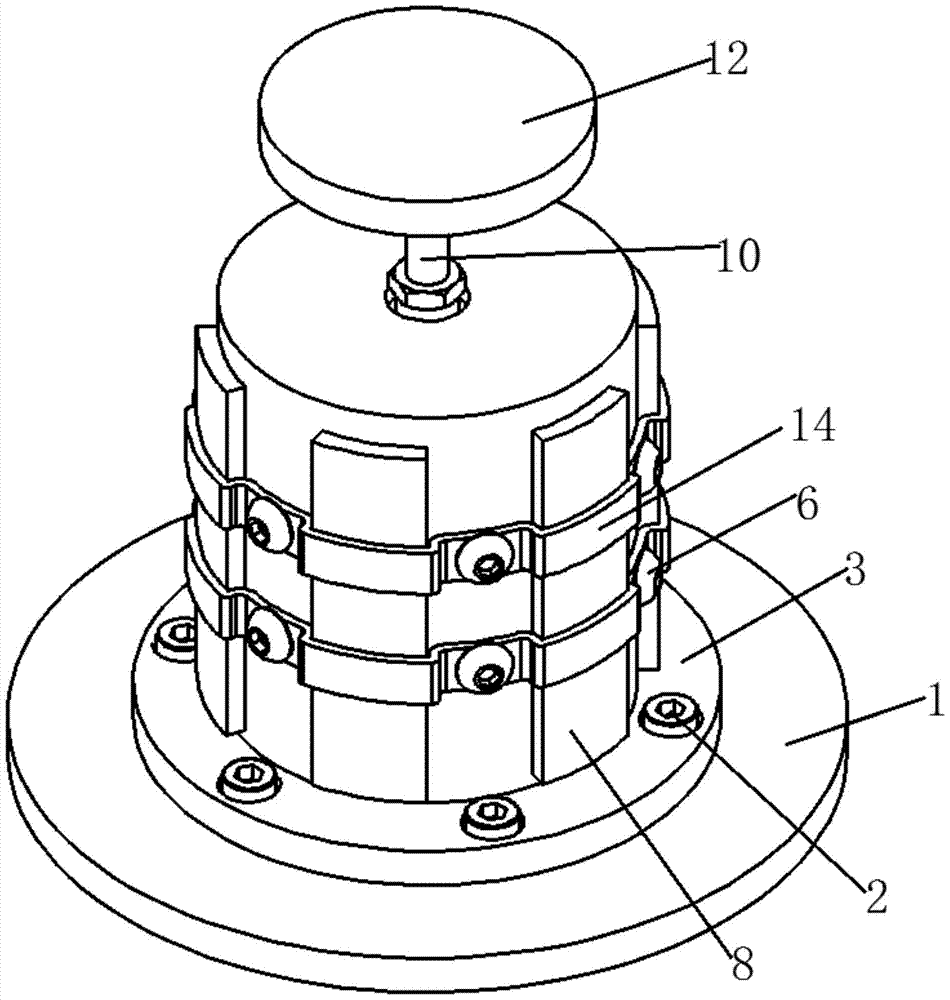

[0025] Embodiment 1, Figure 1 to Figure 13 A magnetorheological elastomer shock absorber is given, including a fixed outer cylinder 3, a magnetorheological elastomer 5, an intermediate cylinder 7, a coil 8, a top cylinder 9, a piston assembly 10, an acceleration sensor 11, and a buffer installation Plate 12, bottom cylinder 13 and coil fixing ring 14, the bottom cylinder 13 is connected to one end of the middle cylinder 7, the other end of the middle cylinder 7 is connected to the top cylinder 9, and the bottom cylinder 13 is connected to one end of the middle cylinder 7. A fixed partition 4 is also installed, and the other end of the middle cylinder 7 and the top cylinder 9 are also equipped with a fixed partition 4; a small cylindrical cavity is formed between the fixed partitions 4, and a magnetorheological elastomer 5 and a magnetorheological elastomer 5 are installed in the small cylindrical cavity. Piston sheet 102, the piston sheet 102 is located between the magnetorhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com