Laser guide type ground glue-injection machine

A technology of laser guidance and glue injection machine, which is applied in the direction of construction and building construction, can solve the problems of not being able to meet the requirements of industrial production and construction assembly, not being able to meet the requirements of factory production and construction assembly, inconvenient replacement and reuse, etc., to achieve The effect of glue feeding and glue injection is convenient, the product quality is guaranteed, and the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing of description, but protection scope of the present invention is not limited thereto:

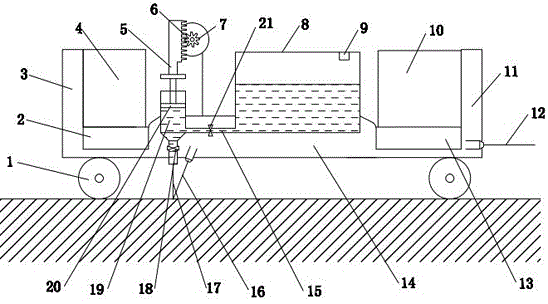

[0022] like figure 1 The laser-guided ground glue injection machine shown includes a frame and a roller 1 arranged at the bottom of the frame. There are 4 rollers 1, which are respectively arranged on the four corners of the frame. The two sides of the frame are respectively For the left side wall 3 and the right side wall 11, a base is set in the frame, and the base includes a left base 2, a middle base 14 and a right base 13, and the left base 2 is adjacent to the left side wall 3 of the frame, and the right base 13 Adjacent to the right side wall 11 of the frame, the left side wall 3 is provided with a motor 4, the right base 13 is provided with a controller 10, and the middle base 14 is provided with a glue injection device, which includes a glue storage room 8 and a glue injector, a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com