Independently mountable piezoelectric jacquard comb

A piezoelectric and piezoelectric ceramic chip technology, used in textiles and papermaking, knitting, warp knitting, etc., can solve problems such as damage, Jacquard work failure, easy entry of foreign objects, etc., to prevent the entry of foreign objects and dust, reduce Installation cost, effect of improving swing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings. It should be clear that the specific embodiments of the present invention described in the drawings are only for illustrating the present invention, and they are not strictly drawn according to actual size and proportion. Therefore, the drawings in the present invention should not be construed as any limitation of the present invention. The protection scope of the present invention is defined by the claims.

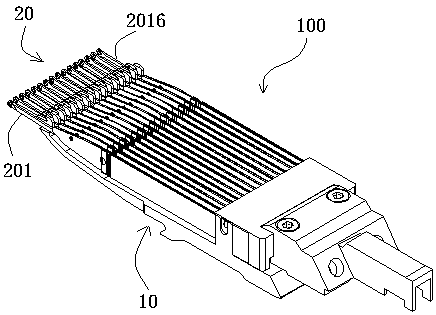

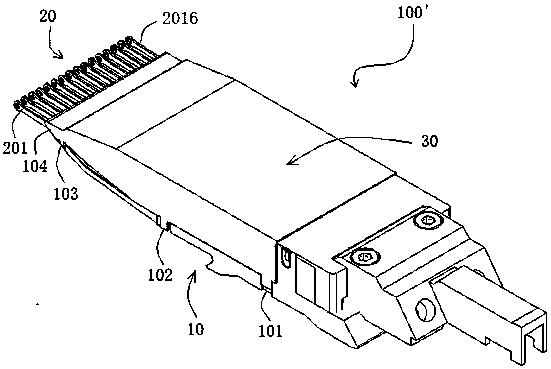

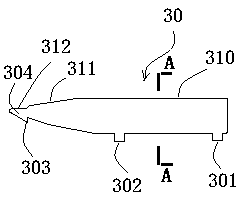

[0022] Such as figure 2 , 3A , 3B, 3C, 4A, 4B, and 5, the independently installable piezoelectric jacquard comb 100' of the present invention includes a base 10 and a plurality of yarn guide needles fixed on the base 10 driven by piezoelectric ceramic wafers 20. In addition, an important feature of the present invention is that it further includes a cover 30 . The cover 30 cooperates with the base 10 to conformably cover the plurality of yarn guide needles 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com