Improvement method for laying of corbel pillar bricks of coke dry quenching furnace

A technology for CDQ furnaces and corbels, which is applied in coking oven bricklaying operations, coking ovens, furnace foundations, etc., can solve the problems of broken pillar bricks, harsh working environment of refractory materials, etc., so as to prolong the service life and reduce project costs , Increase the effect of production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

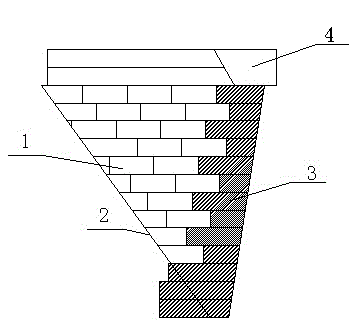

[0028] The method for improving the brick masonry of CDQ furnace corbel pillars of the present invention is characterized in that it comprises the following steps:

[0029] a. Investigation and analysis of the damage of the corbel pillar brick of the CDQ furnace

[0030] (1) The damage characteristics of the facing bricks of the corbel pillar bricks: the inventor is the entrusted unit of the CDQ Coke Oven Construction and Maintenance Engineering Technology Center of China Metallurgical Corporation. Tracking, statistics, and analysis show that the corbel pillar bricks of the CDQ furnace are often damaged, and further analysis is especially serious for the facing bricks of the corbel pillar bricks;

[0031] (2) Structural damage characteristics of corbel support bricks: There are 13 layers of corbel support bricks in the CDQ furnace chute area, with a height of 1300mm. The temperature of the lower part of the corbel brick is about 300°C, and the temperature of the upper part is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com