Application and recycling method and system of polished brick waste slag

A technology of polishing brick waste and waste residue, which is applied in the field of polished brick production, can solve the problems of difficult recycling of polished brick waste, and achieve the effects of simple recycling, good weather resistance, heat resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

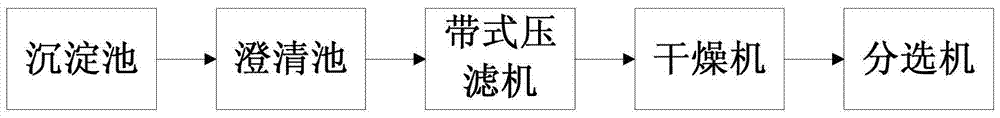

Method used

Image

Examples

Embodiment 1

[0044] The polished brick waste slag is used to prepare PVC flame-retardant corrugated tiles filled with polished brick waste slag, and its raw material composition, in terms of parts by mass, includes the following components:

[0045] 1. 10-50 parts of polished brick waste residue of 325 mesh or above after surface activation treatment;

[0046] 2. PVC resin SG5 100 parts;

[0047] 3. Heat stabilizer 3.5 parts;

[0048] 4. 2.8 parts of lubricant;

[0049] 5. 1.5 parts of processing aids;

[0050] 6. Appropriate amount of colorant.

[0051] The preparation process of using the polished brick waste slag to fill the PVC flame-retardant corrugated tile with the polished brick waste slag is as follows:

[0052] Mixing: first add PVC resin, surface-activated polished brick waste residue and other additives into the high-speed mixer, stir at high speed for 10-15 minutes, and discharge it into the low-speed cold mixer when the material temperature reaches 105-120°C. Stir until th...

Embodiment 2

[0061] The polished brick waste slag is used for the preparation of artificial marble, and its raw material composition, in terms of parts by mass, includes the following components:

[0062] 1. 300-900 parts of polished brick waste residue of 60 mesh or above after surface activation treatment;

[0063] 2. 100 parts of unsaturated polyester resin;

[0064] 3. 2 to 5 parts of curing agent;

[0065] 4. Accelerator 0.5 to 4 parts;

[0066] 5. Appropriate amount of color paste.

[0067] The preparation process of using described polished tile waste slag for artificial marble material is as follows:

[0068] Put the resin into the vacuum mixing tank, add the accelerator and stir for 2 to 5 minutes, then add the color paste and stir for 2 to 5 minutes, then put the polished brick waste aggregate and stir for 20 to 25 minutes, then add the curing agent and vacuum evenly Stir for 20 to 25 minutes, pour the stirred slurry into a glass plate coated with a release agent on the inner...

Embodiment 3

[0073] The polished brick waste slag is used to prepare PVC floor tiles, and its raw material composition, in parts by mass, includes the following components:

[0074] 1. 300-400 copies of polished brick waste residue of 180 mesh or above after surface activation treatment;

[0075] 2. PVC resin (SG3) 100 parts;

[0076] 3. 2 parts of barium stearate;

[0077] 4. 1 part of calcium stearate;

[0078] 5. Plasticizer DOP 30-35 parts;

[0079] 6. 3 parts soybean oil;

[0080] 7. 3-5 copies of ACR-201;

[0081] 8. Light stabilizer 0.5-2 parts.

[0082] The preparation process of using described polished tile waste slag for filling PVC floor tiles is as follows:

[0083] Mixing: first add PVC resin, DOP and other additives into the high-speed mixer, and stir at high speed for 10 to 15 minutes. After the PVC resin powder fully absorbs the plasticizer, then add the weighed polished brick waste slag treated by surface activation at high speed. Stir, and when the temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com