A kind of biaxially stretched polypropylene bag-making film in alpine zone and preparation method thereof

A technology of biaxial stretching and polypropylene, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of less than 500,000 tons of production capacity and limit the company's development, and achieve easy promotion and use, adaptability The effect of strong and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of Antistatic Agent-AT1

[0032] (1) 75 kilograms of octadecylamine, 8.3 kilograms of N, N-bis(hydroxyethyl) cocamide, and 16.7 kilograms of boric acid alkyl alcohol amine ester are added to the high mixer and mixed into the reaction kettle to feed ethylene oxide Addition reaction of 12.5 kg of alkanes to obtain modifier.

[0033] (2) Mix modifiers, monoglycerides, tris(2,4-di-tert-butyl)phenyl phosphite, and polypropylene in percentages by weight of 12%, 8%, 0.3%, and 79.7% evenly to obtain a mixture material;

[0034] (3) Add the mixture into THJ-high-speed, high-torque parallel twin-screw mixing extruder to melt and extrude to make an antistatic masterbatch. The extrusion temperature is 210°C, the pressure is 6Mpa, the speed is 500rpm, and the screw diameter is 75mm. , aspect ratio 40:1;

[0035] (4) cooling and drying the antistatic masterbatch made in step (3), pelletizing;

[0036] (5) The antistatic masterbatch after pelletizing was circulated, dr...

Embodiment 2

[0038] Preparation of antistatic agent-AT2

[0039] (1) 75 kilograms of octadecylamine, 8.3 kilograms of N, N-bis(hydroxyethyl) cocamide, and 16.7 kilograms of boric acid alkyl alcohol amine ester are added to the high mixer and mixed into the reaction kettle to feed ethylene oxide Addition reaction of 12.5 kg of alkanes to obtain modifier.

[0040] (2) Mix modifiers, monoglycerides, tris (2,4-di-tert-butyl) phenyl phosphite, and polypropylene in percentages by weight of 8%, 12%, 0.3%, and 79.7% to obtain a mixture material;

[0041] (3) Add the mixture into THJ-high-speed, high-torque parallel twin-screw mixing extruder to melt and extrude to make an antistatic masterbatch. The extrusion temperature is 210°C, the pressure is 6Mpa, the speed is 500rpm, and the screw diameter is 75mm. , aspect ratio 40:1;

[0042] (4) cooling and drying the antistatic masterbatch made in step (3), pelletizing;

[0043] (5) The antistatic masterbatch after pelletizing was circulated, dried, ...

Embodiment 3

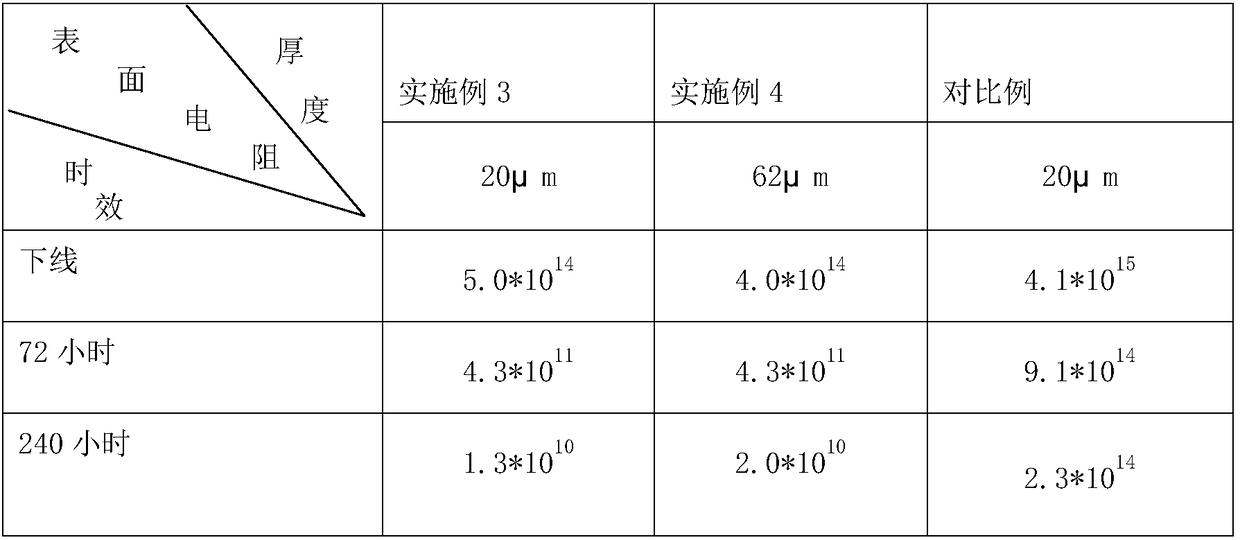

[0045]The bag-making film of the present embodiment includes raw materials in the following percentages by weight: the upper surface layer includes: homopolypropylene 97.5%, anti-sticking agent 2.5%; the core layer includes: homopolypropylene 97.4%, antistatic agent 1.6%, smooth agent 1.0%; the lower surface layer includes: homopolypropylene 98%, anti-sticking agent 2.0%; wherein the antistatic agent is AT1 prepared in Example 1; the thickness of the upper surface layer is 1.0 μm, and the thickness of the core layer is 18.0 μm , The thickness of the lower surface layer is 1.0 μm.

[0046] Concrete preparation method is as follows:

[0047] (1) Feeding: Put the raw materials of the upper surface layer, the core layer and the lower surface layer into the respective corresponding twin-screw extruders;

[0048] (2) Extrusion and plasticization: melt and extrude the raw materials in the twin-screw extruder at a temperature of 250°C;

[0049] (3) Cast sheet cooling: The melt extru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com