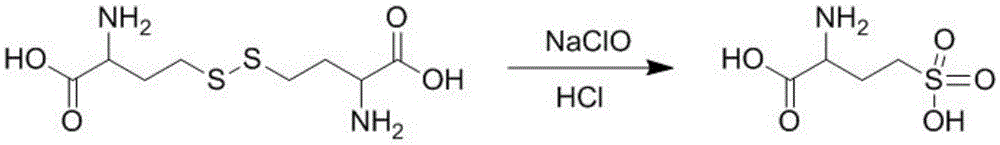

DL-homocysteic acid preparation method

A high sulfoalanine and homocystine technology is applied in the field of preparation of DL-homosulfoalanine, which can solve the problem of high toxicity of DL-homosulfoalanine, low product quality, and product purity. Problems such as failure to meet requirements, to achieve the effects of pollution prevention, high quality, and clean preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A preparation method of DL-homosulfoalanine comprises: dissolving 268gDL-homocystine in 150g hydrochloric acid, heating up to 55°C for the first time, then adding 1862.5g sodium hypochlorite dropwise, after the dropwise addition, and then Raise the temperature twice to 75°C for 1.5 hours to obtain the reaction liquid; concentrate the reaction liquid obtained in step 1 to a small volume, then add an appropriate amount of ethanol to crystallize, then filter to obtain solid crystals, and then dry the crystals to obtain the target The product was 247gDL-homosulfoalanine, the yield was 67.5%, and the purity was 93.4%.

Embodiment 2

[0019] A kind of preparation method of DL-homosulfoalanine comprises: 268gDL-homocystine is dissolved in 200g hydrochloric acid, be warmed up to 60 ℃ for the first time, then dropwise add 2000g sodium hypochlorite, after dropwise addition, then second Raise the temperature to 80°C and react for 2 hours to obtain the reaction solution; concentrate the reaction solution obtained in step 1 to a small volume, then add an appropriate amount of ethanol to crystallize, then filter to obtain solid crystals, and then dry the crystals to obtain the target product 300gDL-homosulfoalanine, the yield is 82%, and the purity is 98.2%.

Embodiment 3

[0021] A preparation method of DL-homosulfoalanine comprises: dissolving 268gDL-homocystine in 250g hydrochloric acid, heating up to 65°C for the first time, then adding 2160.5g sodium hypochlorite dropwise, after the dropwise addition, then Raise the temperature to 85°C for 2.5 hours to obtain the reaction liquid; concentrate the reaction liquid obtained in step 1 to a small volume, then add an appropriate amount of ethanol to crystallize, then filter to obtain solid crystals, and then dry the crystals to obtain the target The product was 300gDL-homosulfoalanine, the yield was 82%, and the purity was 98.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com