Elevator door plate

A door panel and elevator technology, applied in the field of machinery, can solve the problems such as the decrease and disappearance of the sealing effect of the fireproof expansion sealing strip, affecting the service life of the elevator door, etc., and achieve the effect of improving the smoke and heat insulation effect and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

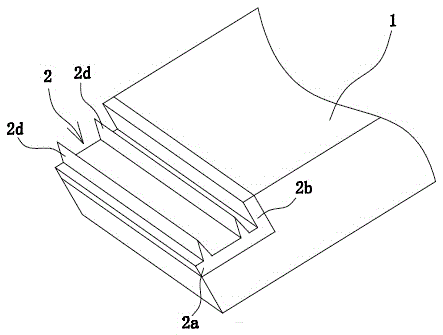

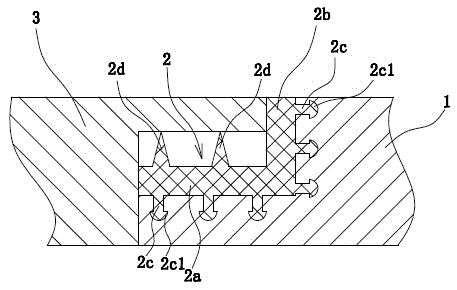

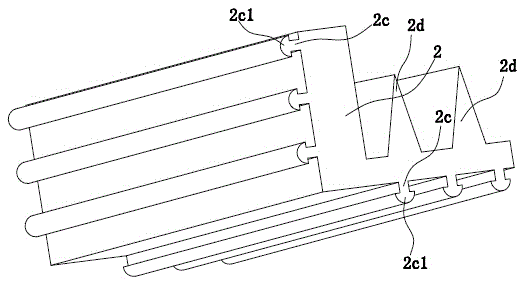

[0025] Such as figure 1 As shown, this elevator door panel is made up of body 1 and fireproof expansion sealing strip 2.

[0026] The main body 1 is in the shape of a long plate. One end of the main body 1 has an L-shaped step. The fireproof expansion sealing strip 2 is L-shaped and located in the step. At this time, the fireproof expansion sealing strip 2 is parallel to the step. In this example, if figure 1 As shown, the width of the fireproof expansion sealing strip 2 is equal to the width of the body 1; the height of the fireproof expansion sealing strip 2 is equal to the height of the steps.

[0027] Specifically, the fireproof expansion sealing strip 2 includes a horizontally arranged connecting portion 1 2a and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com