Extractant recovery method and system of technology for preparing adiponitrile trough hydrocyanating allyl acetonitrile

An extraction agent and hydrocyanation technology, applied in organic chemistry, carboxylic acid nitrile purification/separation, etc., to achieve the effect of optimizing heat exchange network, reducing production cost, and realizing effective utilization of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

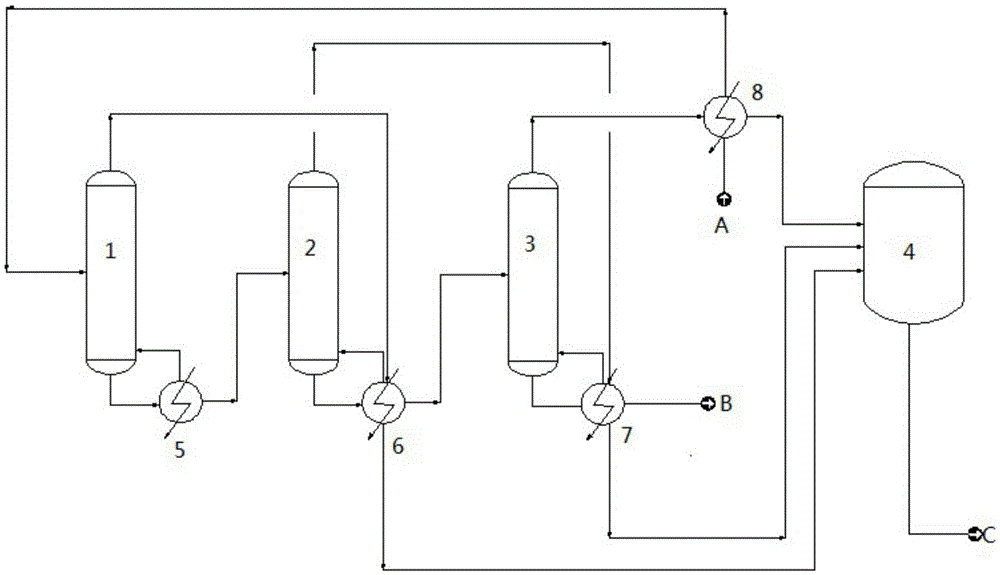

Embodiment 1

[0023] The raffinate A32746kg / h of the adiponitrile extraction process is preheated to 40°C through the third-effect evaporation tower top heat exchanger 8 and enters the first-effect evaporation tower 1. In terms of mass percentage, the raffinate A contains 70% Extractant, 20% catalyst and 10% auxiliary agent. The pressure of the first effect evaporation tower 1 is 200kPaG, and the extraction agent vapor output from the bottom of the first effect evaporation tower 1 enters the second effect evaporation tower 2, the temperature is 130°C, and the pressure is reduced by 70kPa for further decompression evaporation, and then evaporates from the second effect The unevaporated liquid output from the bottom of the tower 2 enters the three-effect evaporation tower 3, the temperature is 115°C, and the pressure is further reduced by 80kPa. Finally, the catalyst and auxiliary agent B are output from the bottom of the three-effect evaporation tower 3, and the extraction agent steam output...

Embodiment 2

[0026] The raffinate A37746kg / h of the adiponitrile extraction process is preheated to 80°C through the third-effect evaporation tower top heat exchanger 8 and enters the first-effect evaporation tower 1. In terms of mass percentage, the raffinate A contains 80% Extractant, 15% catalyst and 5% additives. The pressure of the first-effect evaporation tower 1 is 20kPaG, and the extraction agent vapor output from the bottom of the first-effect evaporation tower 1 enters the second-effect evaporation tower 2, the temperature is 130°C, and the pressure is reduced by 40kPa for further decompression evaporation, and then evaporates from the second effect The unevaporated liquid output from the bottom of the tower 2 enters the three-effect evaporation tower 3, the temperature is 115°C, and the pressure is further reduced by 40kPa. Finally, the catalyst and auxiliary agent B are output from the bottom of the three-effect evaporation tower 3, and the extraction agent steam output from th...

Embodiment 3

[0029] The raffinate A38746kg / h of the adiponitrile extraction process is preheated to 60°C through the top heat exchanger 8 of the third effect evaporation tower and enters the first effect evaporation tower 1. In terms of mass percentage, the raffinate A contains 75% Extractant, 18% catalyst and 7% additives. The pressure of the first-effect evaporation tower 1 is 160kPaG, and the extraction agent vapor output from the bottom of the first-effect evaporation tower 1 enters the second-effect evaporation tower 2, the temperature is 130°C, and the pressure is reduced by 120kPa for further reduced-pressure evaporation, and then evaporated from the second effect The unevaporated liquid output from the bottom of the tower 2 enters the three-effect evaporation tower 3, the temperature is 115°C, and the pressure is further reduced by 40kPa. Finally, the catalyst and auxiliary agent B are output from the bottom of the three-effect evaporation tower 3, and the extraction agent steam ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com