A kind of spherical ordered mesoporous silica and its preparation method

A mesoporous silica and grade technology, applied in the field of mesoporous materials, can solve the problems of difficult control, irregular particles, and low hydrothermal stability of the structure, and achieve the effect of simple preparation process and simple and direct method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

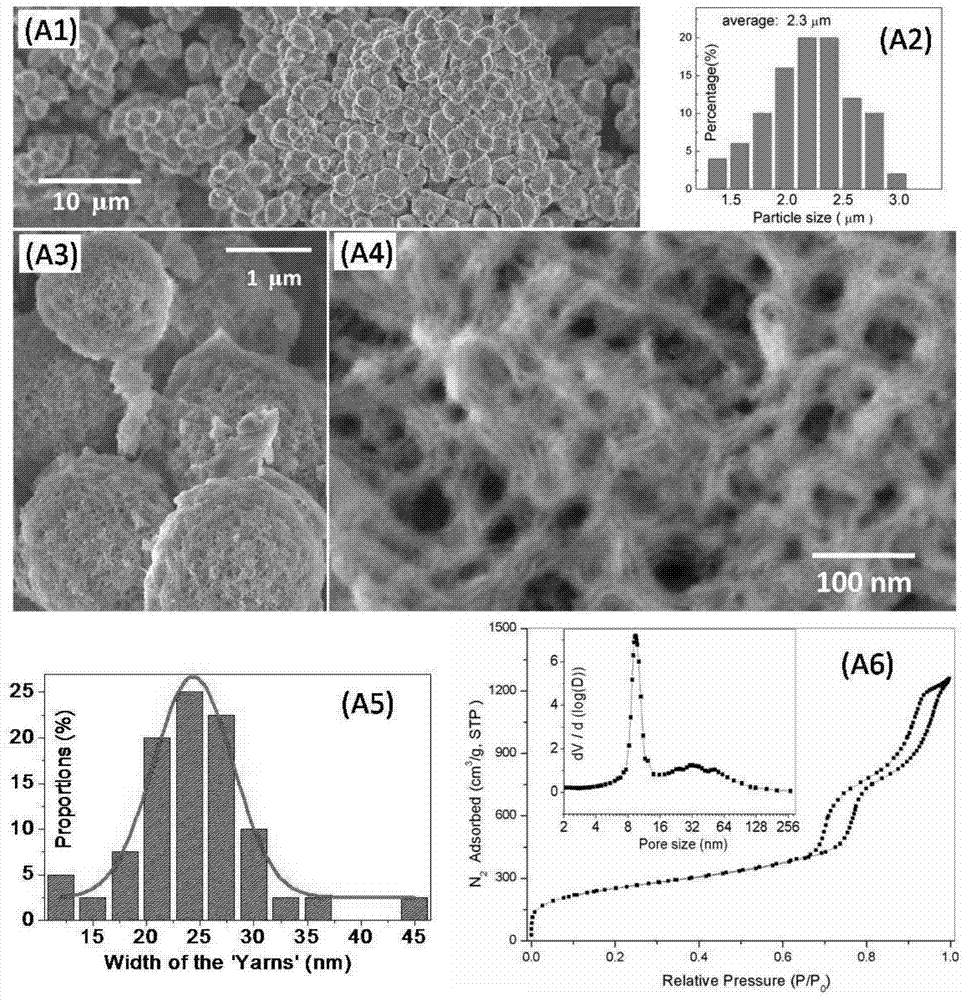

[0036] Spherical ordered graded mesoporous silica, which is a kind of graded mesoporous SiO with coil structure 2 , the wires of the coils have the first-order pore structure, and the second-order pores exist between the wires, the average width of the wires is 25nm, the first-order mesopores are arranged in an orderly structure, and the The average pore diameter is 9.4nm, the average pore diameter of the secondary pores is 33.7nm, and the average particle diameter of silica is 2.3μm.

[0037] The preparation method of spherical ordered grade mesoporous silica specifically comprises the following steps:

[0038] step 1:

[0039] (1) preparation 80g mass fraction is the clear aqueous solution of P123 surfactant of 2.5%, wherein, the molecular weight of P123 is 5800;

[0040] (2) adding 11.5g concentration is the concentrated hydrochloric acid of 37%;

[0041] (3) Place in a water bath, the temperature of the water bath is 36°C, stir and mix evenly to obtain a mixed solution; ...

Embodiment 2

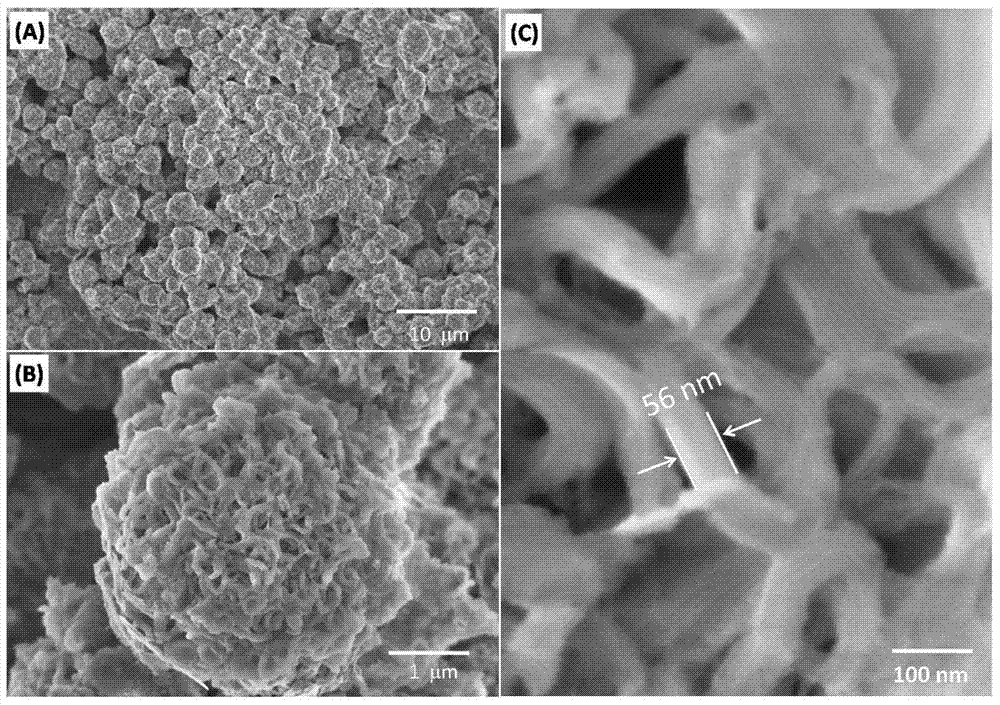

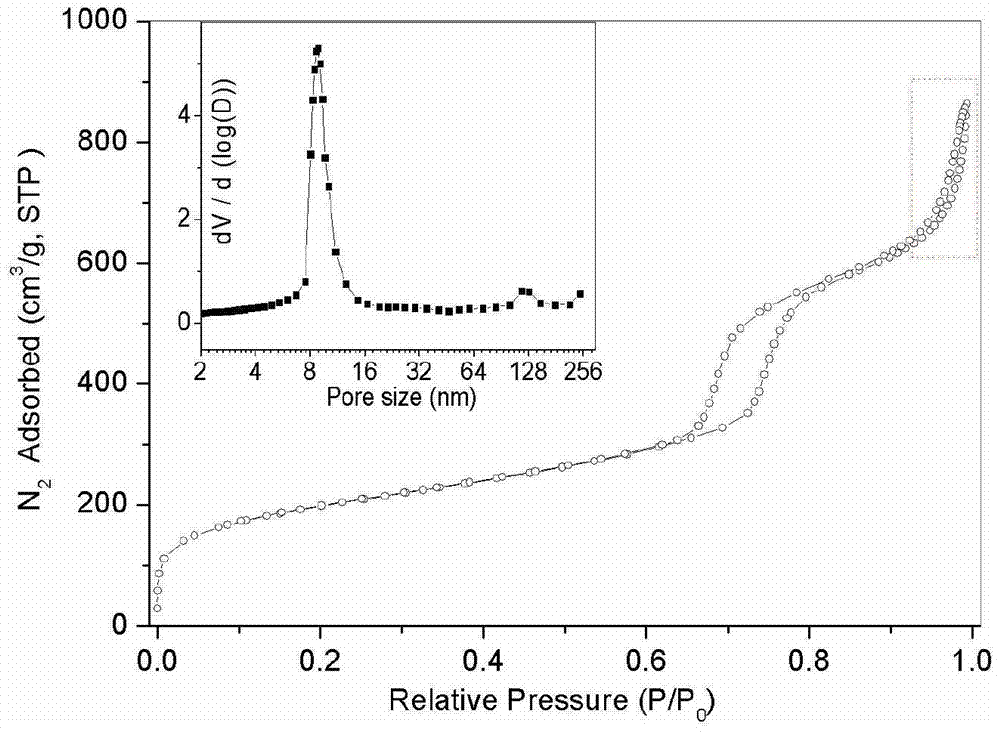

[0050] Spherical ordered graded mesoporous silica, which is a kind of graded mesoporous SiO with coil structure 2 , the lines of the coils have the first-order pore structure, and the second-order pores exist between the lines. The average width of the lines is 56nm. The first-order mesopores are arranged in an orderly structure, and the first-order mesopores The average pore diameter is 8.8nm, the average pore diameter of the secondary pores is 128nm, and the average particle diameter of silicon dioxide is 3.0μm.

[0051] The preparation method of spherical ordered grade mesoporous silica specifically comprises the following steps:

[0052] step 1:

[0053] (1) preparation 80g mass fraction is the clear aqueous solution of P123 surfactant of 2.5%, wherein, the molecular weight of P123 is 5800;

[0054] (2) adding 11.5g concentration is the concentrated hydrochloric acid of 37%;

[0055] (3) Place in a water bath, the temperature of the water bath is 31°C, stir and mix even...

Embodiment 3

[0064] Spherical ordered graded mesoporous silica, which is a kind of graded mesoporous SiO with coil structure 2 , the lines of the coils have the first-order pore structure, and the second-order pores exist between the lines. The average width of the lines is 40nm. The first-order mesopores are arranged in an orderly structure, and the first-order mesopores The average pore diameter is 8.9nm, the average pore diameter of the secondary pores is 78.4nm, and the average particle diameter of silica is 3.1μm.

[0065] The preparation method of spherical ordered grade mesoporous silica specifically comprises the following steps:

[0066] step 1:

[0067] (1) preparation 80g mass fraction is the clear aqueous solution of P123 surfactant of 2.5%, wherein, the molecular weight of P123 is 5800;

[0068] (2) adding 11.5g concentration is the concentrated hydrochloric acid of 37%;

[0069] (3) Place in a water bath, the temperature of the water bath is 36°C, stir and mix evenly to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com