Ingot cutting device

A cutting device and crystal ingot technology, which is applied to fine working devices, working accessories, stone processing equipment, etc., can solve problems such as affecting the quality of sliced wafers and weakening the cutting force of wire saws.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

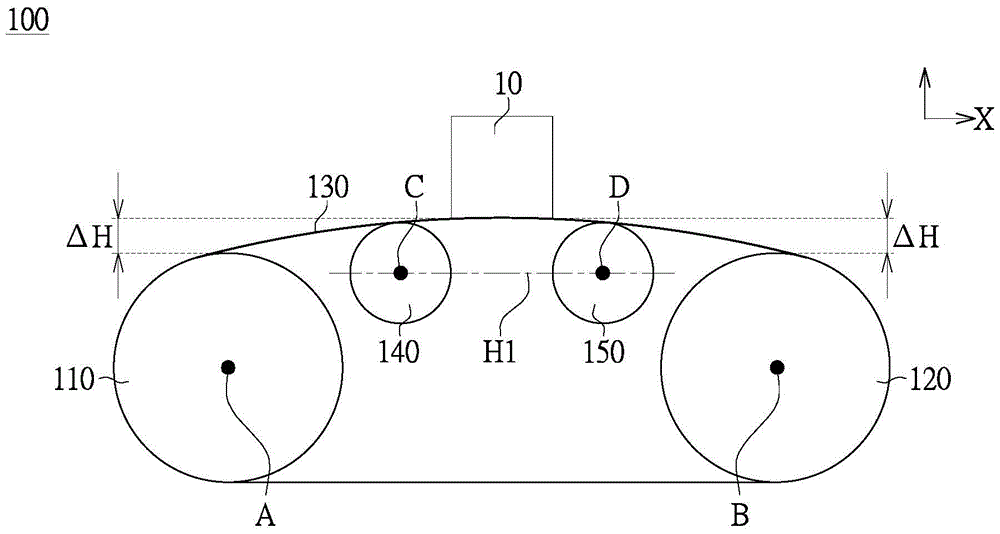

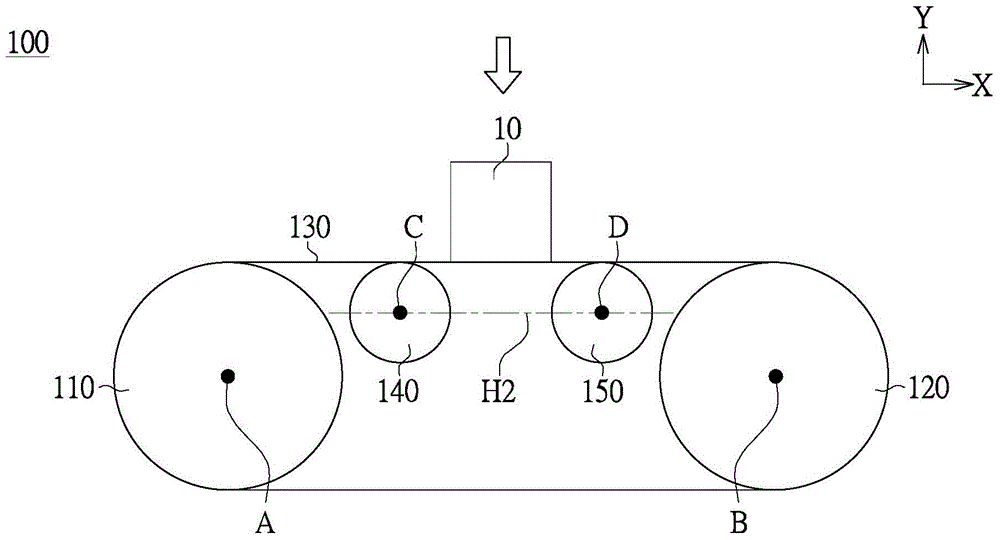

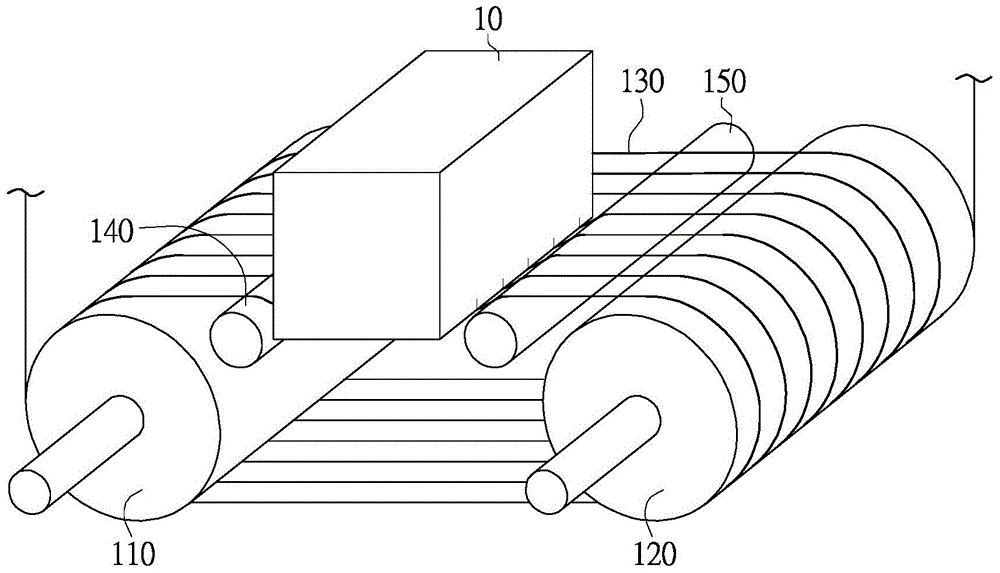

[0030] Please refer to Figure 1 to Figure 3 , Which respectively show schematic diagrams of the ingot cutting device 100 according to an embodiment of the present invention. The ingot cutting device 100 includes a first main roller 110, a second main roller 120, a wire saw 130, and two auxiliary rollers 140 / 150 (ie, a first auxiliary roller 140 and a second auxiliary roller 150). The first main roller 110 and the second main roller 120 are driven to rotate by a motor system (not shown in the figure), and the wire saw 130 is driven by the first main roller 110 and the second main roller 120. The first auxiliary roller 140 and the second auxiliary roller 150 are driven by the wire saw 130. The auxiliary roller 140 / 150 is located between the first main roller 110 and the second main roller 120, and the auxiliary roller 140 / 150 is not connected to the motor system, but is driven by the wire saw 130 to rotate. For the convenience of description, the auxiliary rollers 140 / 150 mentio...

no. 2 example

[0042] Please refer to Figure 5 and Image 6 , Which shows a schematic diagram of a crystal ingot cutting device 200 according to an embodiment of the present invention. The ingot cutting device 100 includes a pair of first main rollers 210, a pair of second main rollers 220, a wire saw 230, and two auxiliary rollers 240 (ie, two first auxiliary rollers). Each first main roller 110 and each second main roller 120 are driven to rotate by a motor system, and the wire saw 230 is driven by the first main roller 210 and the second main roller 220 and moves back and forth in a high-speed loop. Each auxiliary roller 240 is located between the first main roller 210 and the second main roller 220, and each is driven by the wire saw 230 to rotate. Although this embodiment takes four main rollers 210 / 220, a wire saw 230, and two auxiliary rollers 240 as an example, the method of cutting the ingot is similar to the first embodiment, and the difference is that two ingots 20 can be simultan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com