Bin device

A silo and silo body technology, applied in the field of wood pallet processing, can solve problems such as nailing troubles, low efficiency, and disordered nail order, and achieve the effect of simple and convenient operation, convenient nailing, and convenient and orderly arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

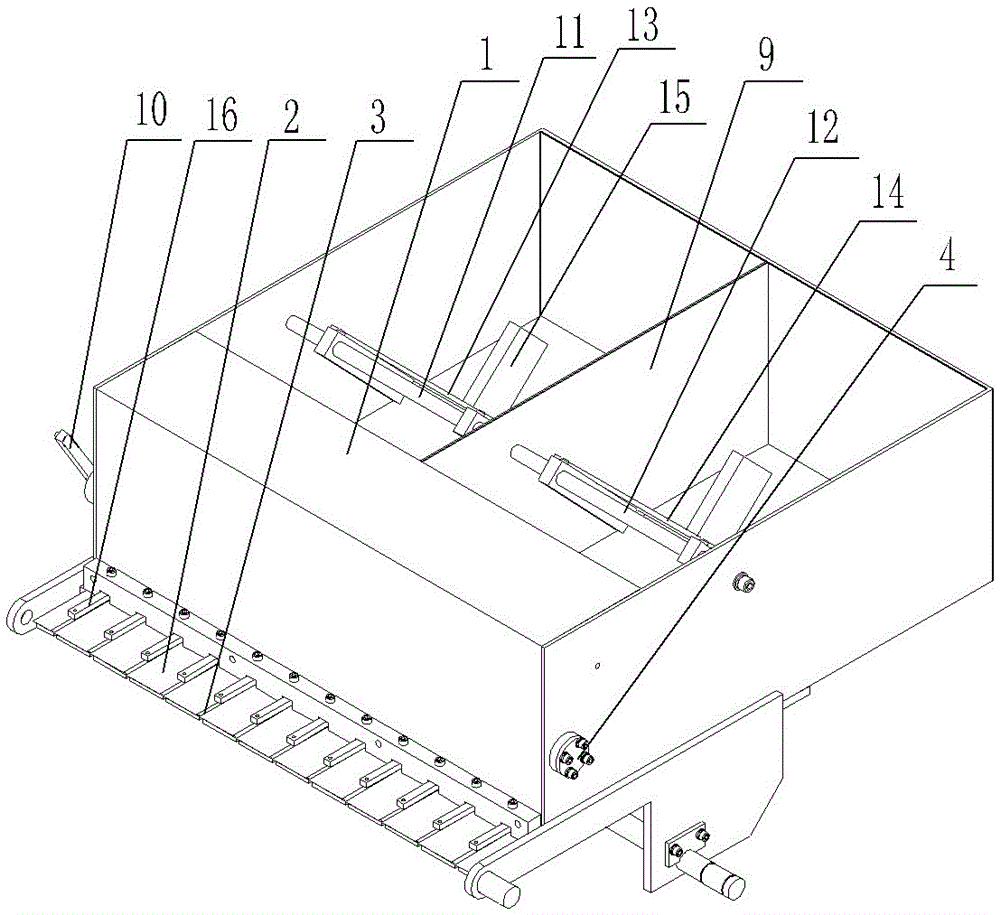

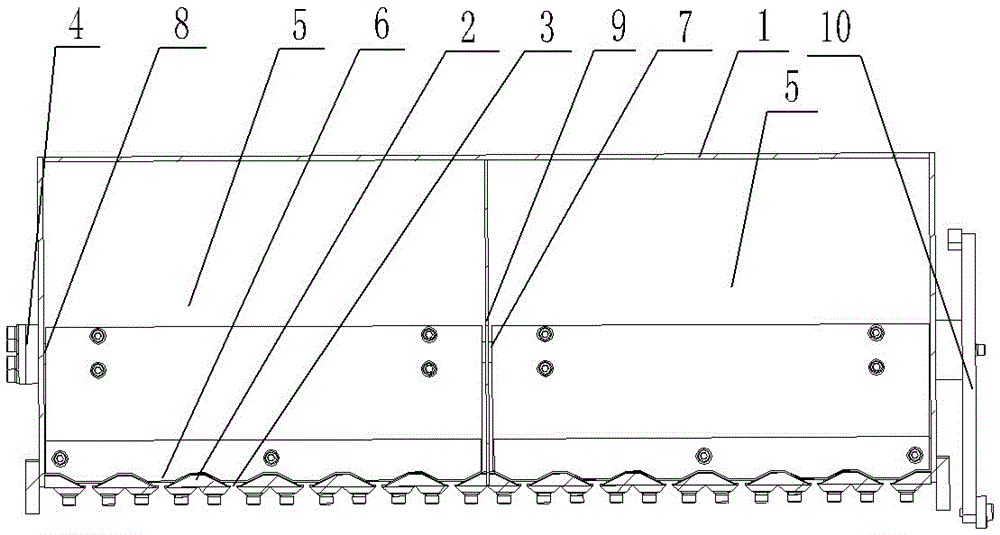

[0013] See figure 1 , figure 2 As shown, a silo device comprises a bin body 1 with upper and lower ends open, a nail guide plate 2 is fixedly installed at the opening of the lower end of the bin body 1, and a nail guide groove 3 is formed on the nail guide plate 2, and the nail guide groove The notch of 3 is in the shape of a trumpet with a large top and a small bottom, which is convenient for nails to fall automatically. The nail guide groove 3 extends to the outside of the warehouse body 1, and the upper end of the nail guide plate 2 is installed in the warehouse body 1 through the first rotating shaft. Plate 5, the lower end of the first baffle plate 5 is provided with a trapezoidal tooth block 6 that matches the notch of the nail guide groove 3, and the two ends of the first rotating shaft are respectively installed on the bin body 1 through bearings 4 and the two ends are respectively exposed to the bin body 1, A rotating handle 10 is installed on the first rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com