Air curtain protection device and protection method for laser cleaning

A protective device, laser cleaning technology, applied in cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of lens glass burst damage, operator health damage, effective collection of pollutants, etc., to prevent lens from bursting and reduce bursting risk, the effect of preventing endothermic explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

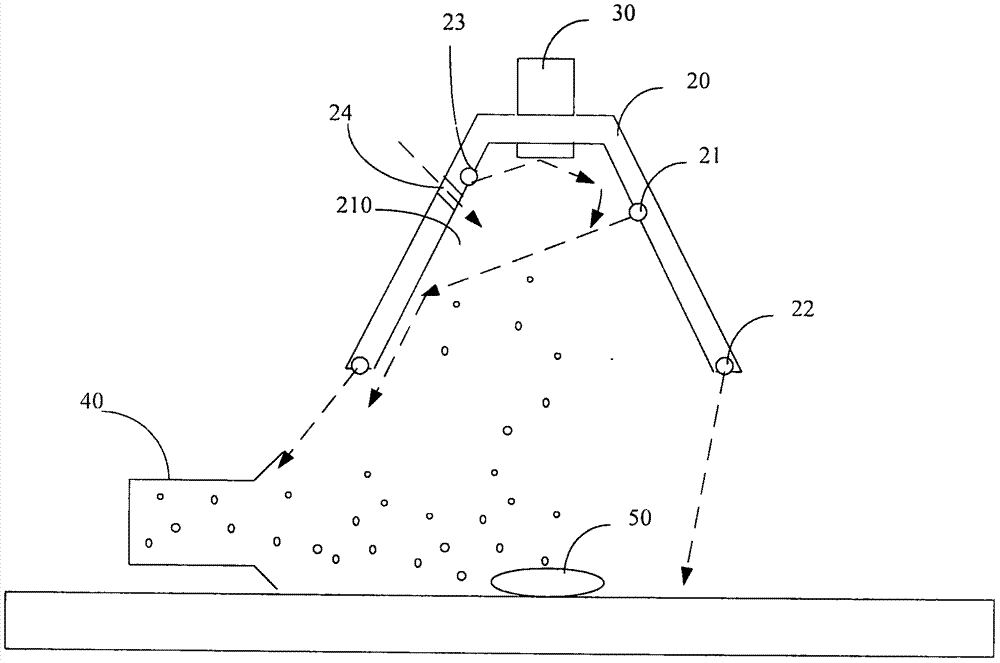

[0038] figure 2 It is the working diagram of the air curtain protection device for laser cleaning of the present invention, as figure 2 As shown, the embodiment of the present invention provides a laser cleaning air curtain protection device, including:

[0039] The protective cover 20 has a trumpet-shaped inner cavity that is thin at the top and thick at the bottom, the laser cleaning lens 30 is sleeved on the upper end of the inner cavity, and the lower end of the inner cavity has an opening;

[0040] The first air outlet array 21 connected to the high-pressure air pipeline is arranged on the side wall of the inner cavity, and the compressed air discharged from the first air outlet array and the side wall form a protective space 210 surrounding the laser lens;

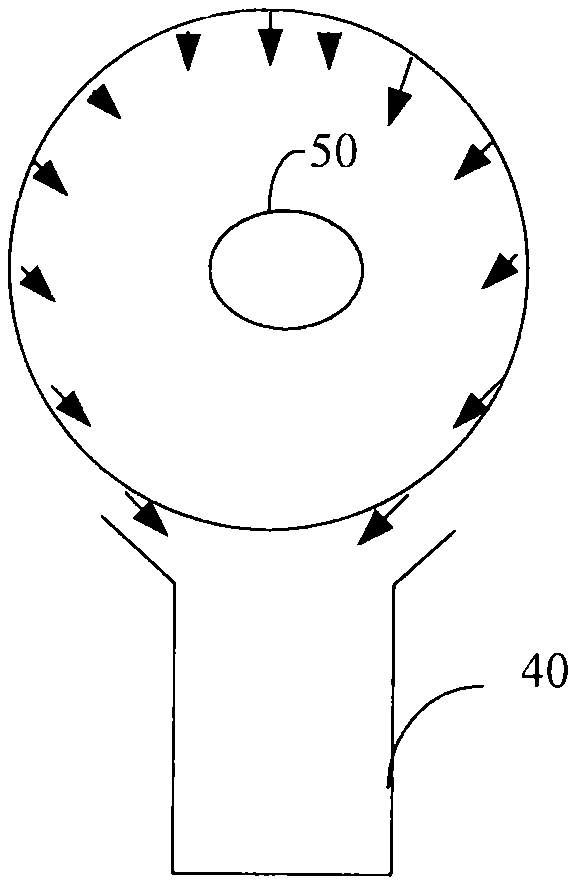

[0041] The suction port 40 is arranged under the side of the protective cover 20;

[0042] The second air outlet array 22 connected with the high-pressure air pipeline is arranged on the periphery of the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com