A glass-lined detachable stirrer with screw connection

A threaded connection and glass-lined technology, which is applied in the field of glass-lined detachable agitators, can solve the problems of reduced thermal expansion and contraction, complicated operation, and difficult processing, and achieves simple installation and disassembly, good anti-corrosion performance, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

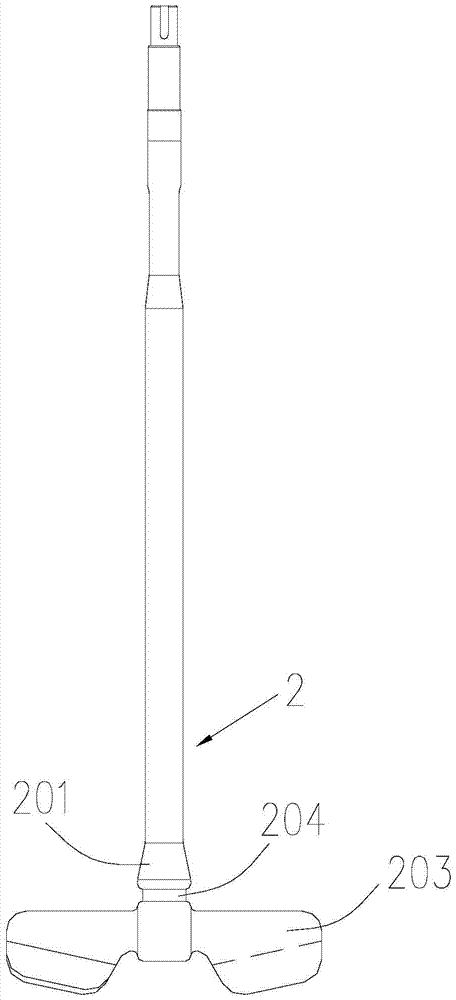

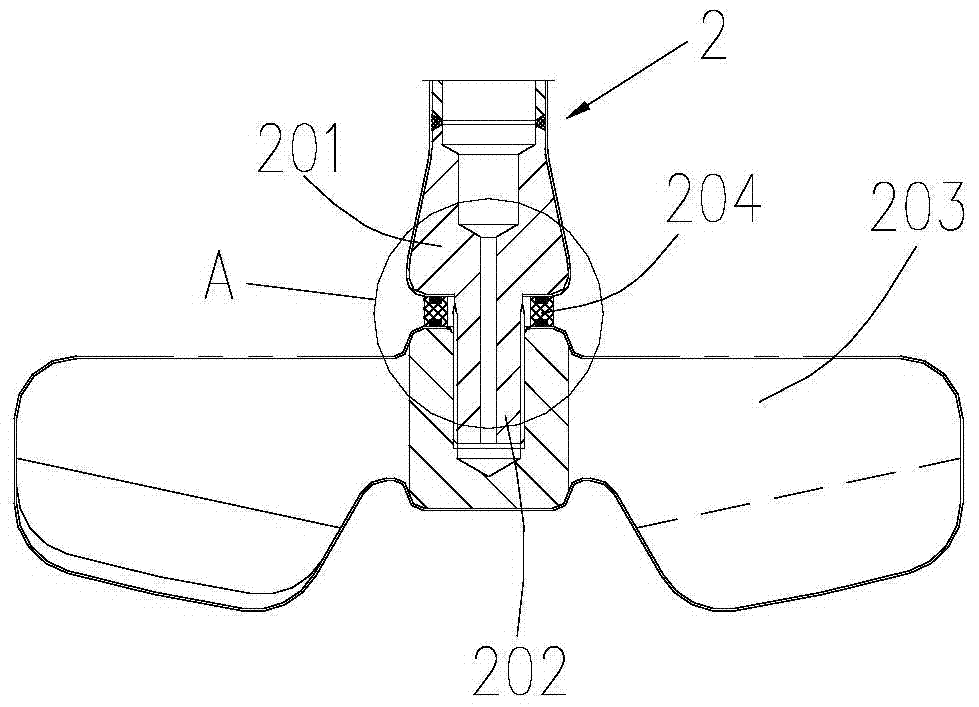

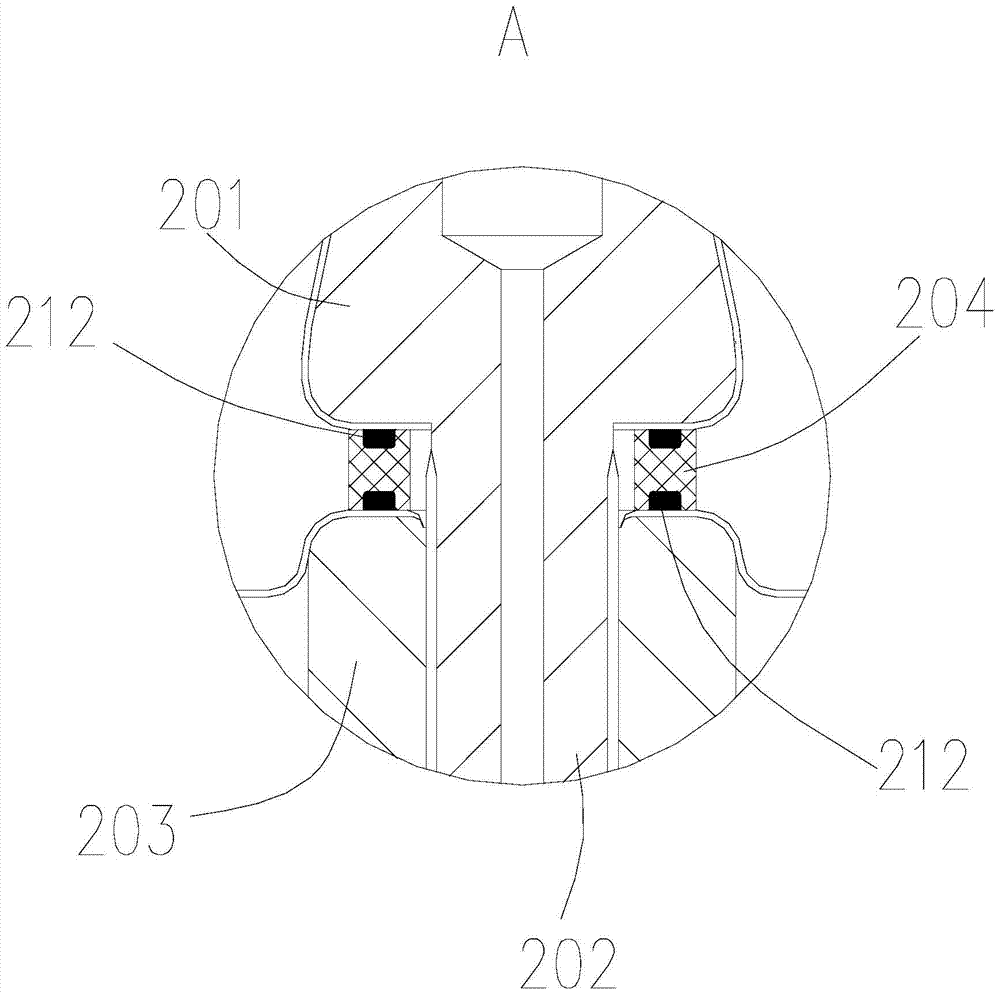

[0045] Such as Figure 1 to Figure 9 The shown embodiment one of a threaded glass-lined detachable stirrer of the present invention includes a driving device 1 and a stirring assembly 2, and the stirring assembly 2 includes a stirring shaft connected in sequence, a first end table 201, a second A screw 202 and a first impeller 203, one end of the stirring shaft away from the first end platform 201 is connected to the drive shaft of the drive device 1; One end of the first screw 202 is threadedly connected to the blind hole 2031, and a sealing seat 204 is attached between the first end platform 201 and the hub of the first impeller 203; The threads are in the same direction, and an anti-reverse device 101 is installed on the drive shaft of the drive device 1 .

[0046] The driving device 1 of the first embodiment drives the stirring shaft to rotate in the clockwise direction, that is, to rotate in the direction in which the first screw 202 is threaded into the blind hole 2031....

Embodiment 2

[0056] Such as Figure 2 to Figure 13 As shown, the difference between Embodiment 2 and Embodiment 1 is that the stirring shaft of Embodiment 1 is an integrated structure, while the stirring shaft of Embodiment 2 is a segmented structure, specifically: the stirring shaft is divided into the first shaft 206 and the first shaft 206. The second shaft 205, the second impeller 207 is fixedly connected between the first shaft 206 and the second shaft 205, and one end of the second shaft 205 away from the second impeller 207 is connected to the drive shaft of the drive device 1, and the first end platform 201 is set At the end of the first shaft 206 away from the second impeller 207 , the second impeller 207 , the first shaft 206 , the first end platform 201 and the first screw 202 are arranged in sequence. Other structures are the same as in Embodiment 1.

[0057] The other structures are the same as the first embodiment, and the corresponding technical effects are also the same as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com