Die head and coating liquid coating method

The technology of coating liquid and die head is applied in the field of die head, which can solve the problem of poor reactivity of bubble coating liquid, and achieve the effect of uniform thickness and maintaining reactivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

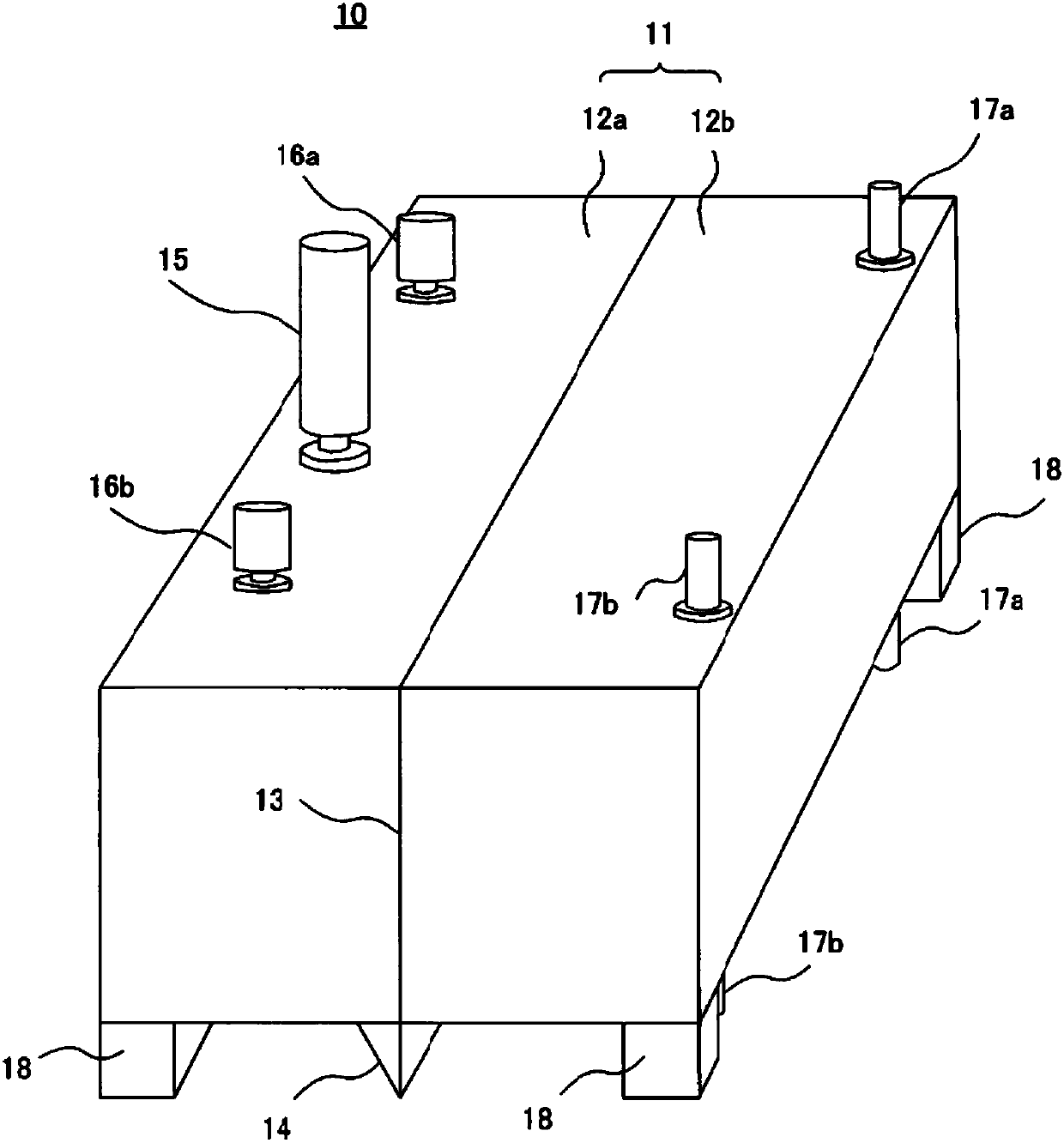

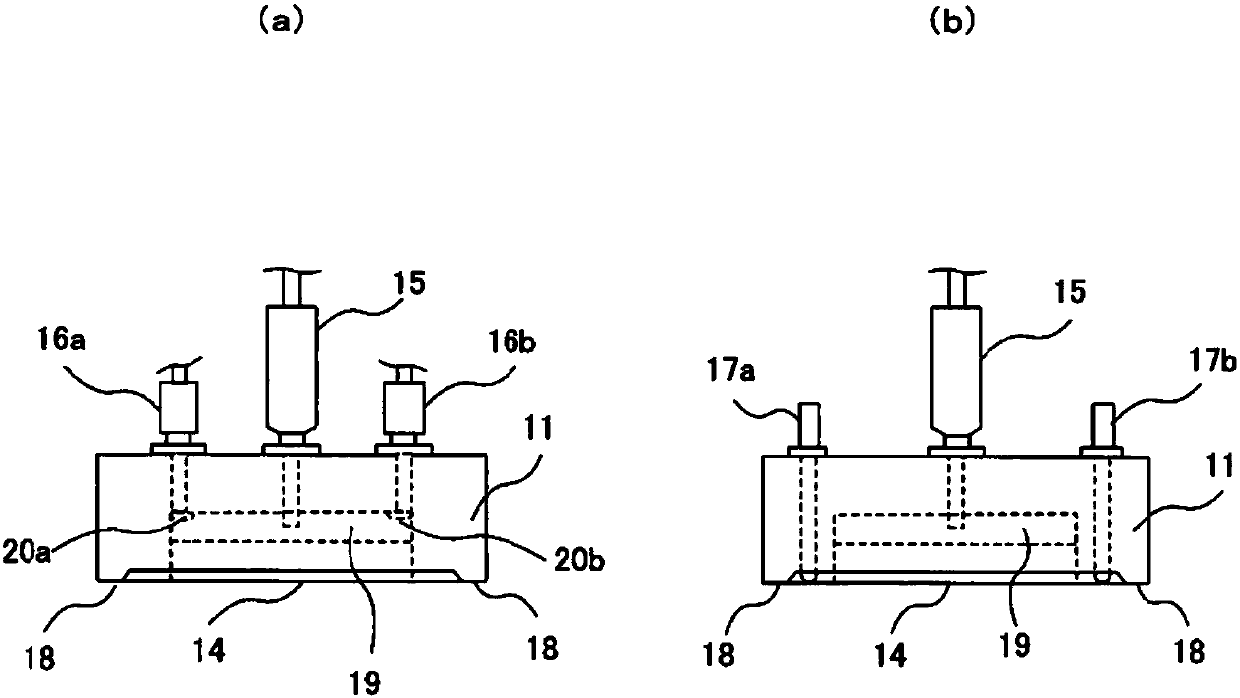

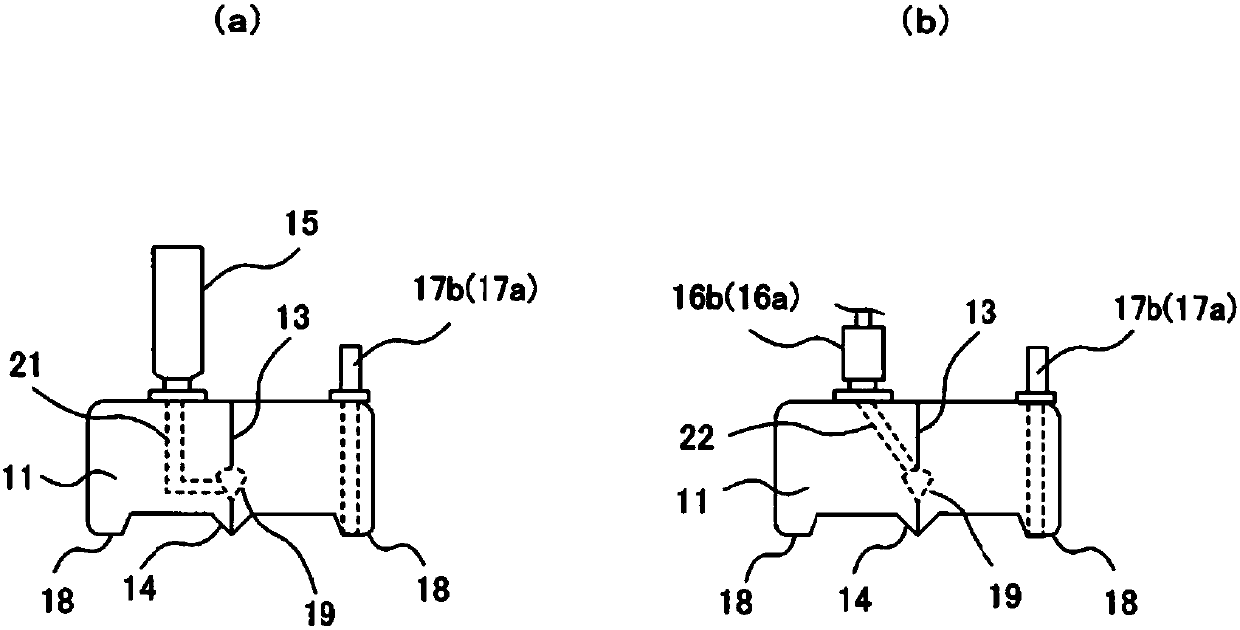

[0026] Hereinafter, an embodiment related to the die head of the present invention will be described. figure 1 It is a perspective view showing an example of the die head 10 according to the embodiment of the present invention. Such as figure 1 As shown, the die head body 11 is formed by a pair of die head members 12a, 12b sandwiching a backing plate 13 therebetween. The backing plate 13 serves as a member for adjusting the width of the slit 14 when the coating liquid is applied from above the member placed on the coating platform of the coating liquid coating device (not shown). The die head main body 11 has a manifold that can temporarily store a coating liquid as described below, and can supply the coating liquid stored in the manifold to the slit 14 .

[0027] The die head main body 11 is provided with a coating liquid injection part 15 and exhaust parts 16a and 16b. The coating liquid injection part 15 is connected to a coating liquid supply part (not shown) and can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com