Thermal shock gasifying electrospray ionization source and mass spectrometry (MS) system

An electrospray mass spectrometry and electrospray technology, which is applied in the direction of mass spectrometer, ion source/gun, particle separator tube parts, etc., can solve the problem of low efficiency of applying heat energy to samples, coupling of chromatographic systems, and easy decomposition of sample molecules when heated To achieve the effect of improving application efficiency, high ionization efficiency, and shortening heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

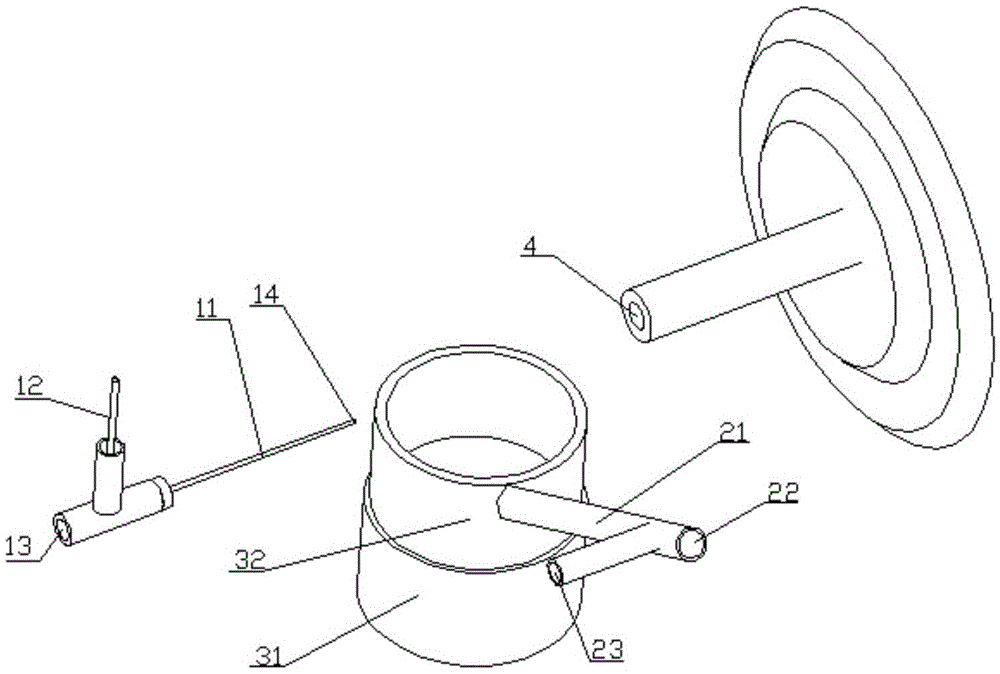

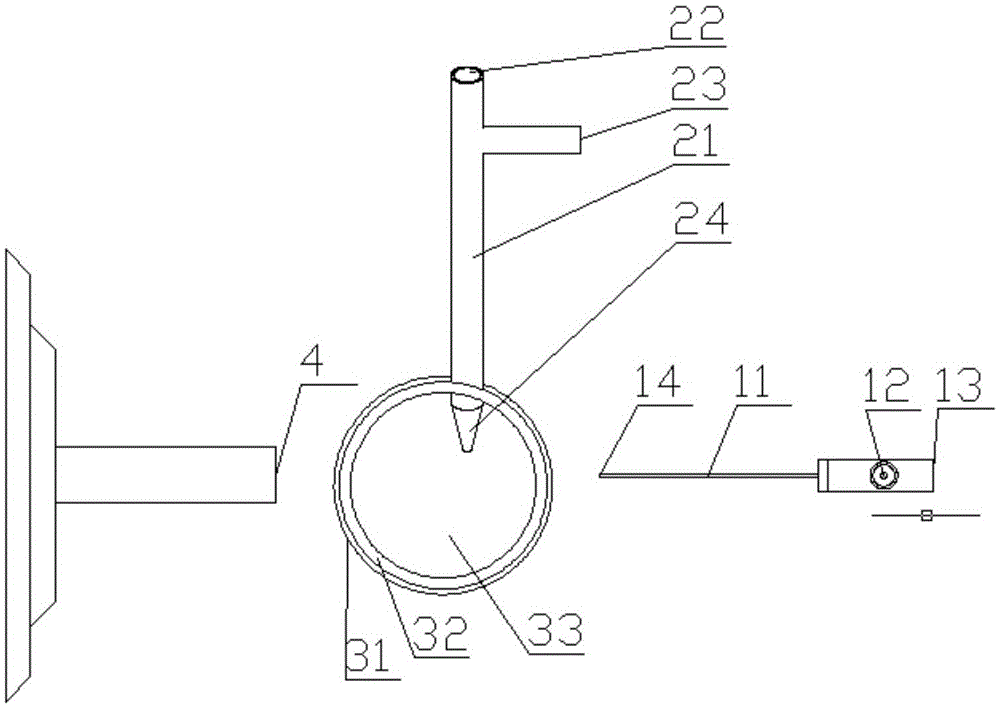

[0038] figure 1 As a specific embodiment of the thermal shock gasification electrospray ionization mass spectrometry system of the present invention, the mass spectrometry system includes two parts, that is, a mass spectrometer part and an ionization source part. Mass spectrometers are of a great variety and are widely used. The ionization source provided by the invention can be connected with any mass spectrometer with an atmospheric pressure interface, such as ion trap mass spectrometry, quadrupole mass spectrometry, time-of-flight mass spectrometry, Fourier transform ion cyclotron resonance mass spectrometry, Magnetic mass spectrometry, orbitrap mass spectrometry, etc. The mass spectrometer of the present invention includes a mass spectrometer inlet 4, through which the ions generated by the ionization source can be introduced into the mass analyzer for mass spectrometry analysis. The ionization source part is the thermal shock gasification electrospray ionization source ...

Embodiment 2

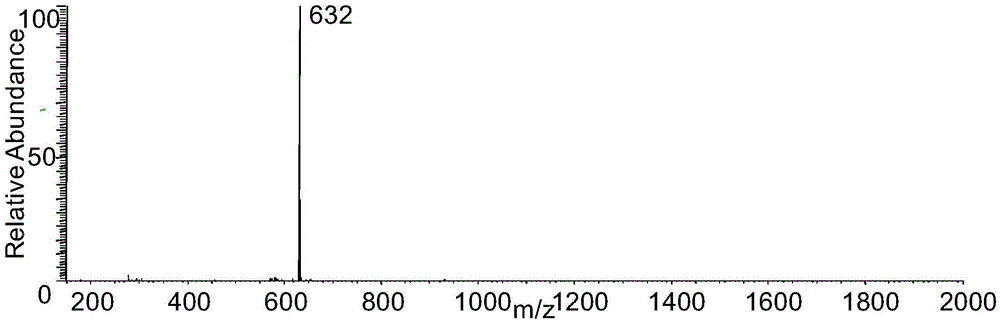

[0050] The thermal shock gasification electrospray ionization mass spectrometry system of the present invention is used to analyze thermally unstable compounds, and mesaconitine is used as the detection object. Add 100 μL of 10 mg / L aconitine methanol solution dropwise to the bottom of the unheated vaporization chamber, and at the same time turn on the electrospray, record the mass spectrometry data, and heat the bottom of the vaporization chamber to 320°C within 2 minutes to gradually vaporize it , but in addition to the background signal of the electrospray solvent in the collected mass spectrometry data (the spectrum is not listed), there is no signal related to mesoaconitine, indicating that mesoaconitine is completely decomposed during the heating process. Using the thermal shock gasification electrospray ionization method described in the present invention, first heat the bottom of the gasification chamber to 320°C, and then apply the methanol solution of aconitine to the...

Embodiment 3

[0052] The thermal shock gasification electrospray ionization mass spectrometry system of the present invention is used to analyze biomacromolecules, and horseheart cytochrome C (cytochromec) is used as the detection object. The electrospray solvent is a mixed solution of methanol / water (1:1) containing 0.1% formic acid, and 100 μL of 0.31 mg / ml cytochrome C aqueous solution is added dropwise to the bottom of the unheated vaporization chamber. At the same time, the electrospray is turned on, and the mass spectrometry data is recorded. Afterwards, the vaporization chamber was heated to 400°C within 2 minutes to gradually vaporize it. However, the collected mass spectrometry data did not show any correlation with cytochrome C except for the background signal of the electrospray solvent (the spectrogram is not listed). The signal indicated that cytochrome C was denatured during the heating process and did not enter the mass spectrometry system.

[0053] Using the thermal shock ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com