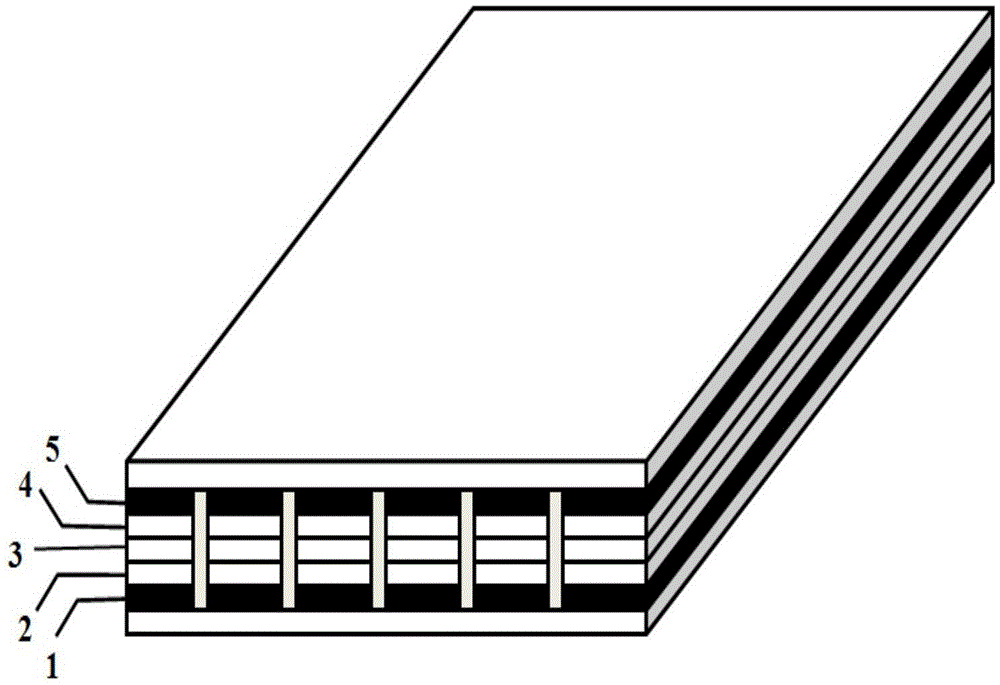

All-solid-state electrochromic device having controllable color-changing area and method for preparing same

An electrochromic device and electrochromic layer technology, which can be used in instruments, nonlinear optics, optics, etc., can solve problems such as adjusting the transmission area, and achieve the effects of less preparation process, simple preparation method and simple packaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

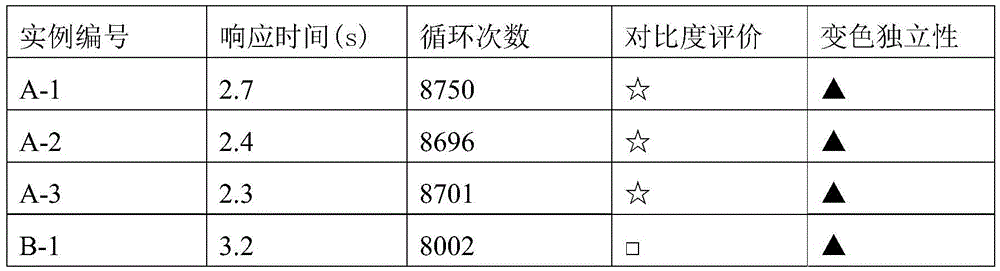

Examples

Embodiment

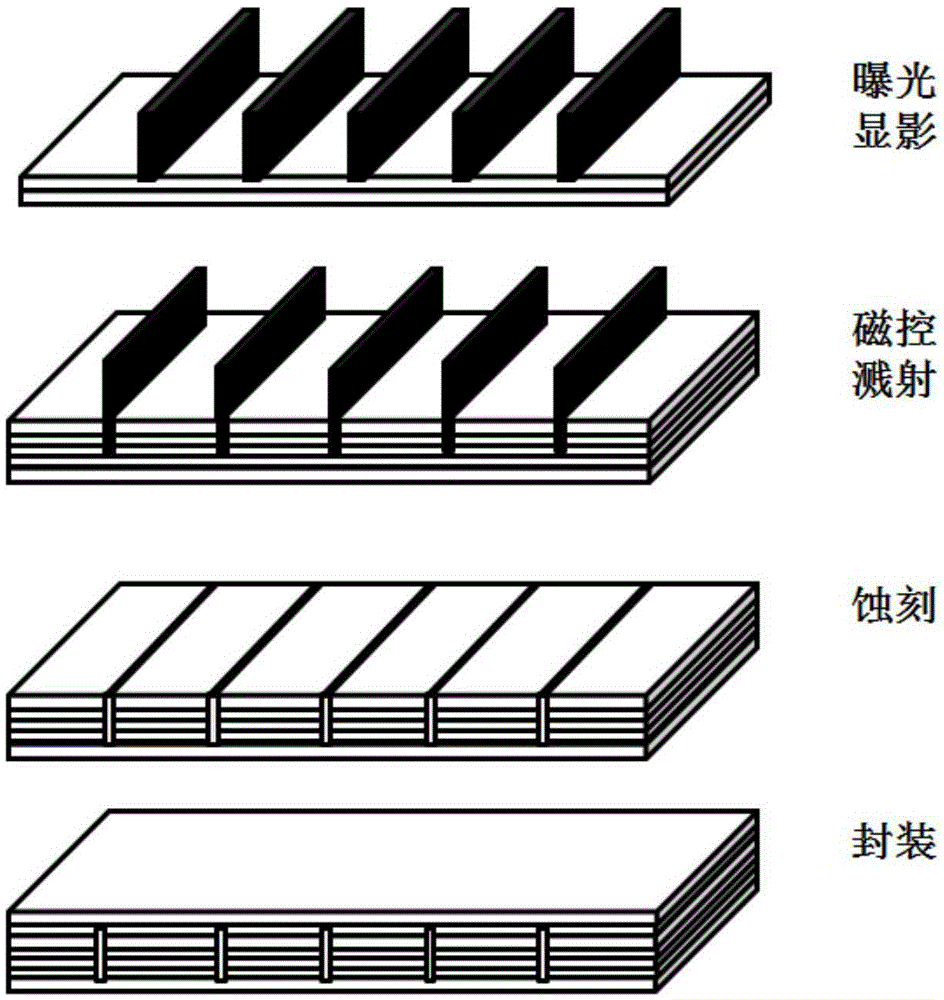

[0034] First prepare some special substrates, the specific steps are on a layer of ITO glass (10*10cm 2 Zhuhai Kaiwei Optoelectronics Technology Co., Ltd.) uses a specific film sheet and a 30μm thick photosensitive dry film (Hangzhou Foster Photovoltaic Materials Co., Ltd.) to transfer graphics. After pasting the film, exposing and developing, a wide Thin dry film with a thickness of 2mm and a height of 2 mm is air-dried for later use. The specific experimental parameters are:

[0035] 1. Film: Use Changzhou Changyao Electronics CYL-M25 to carry out hot bonding under standard pressure, the bonding speed is 1 m / min, and the bonding temperature is 100 °C.

[0036] 2. Exposure: Use Zhisheng Technology M-552 exposure machine for exposure, use stouffer 41-grid exposure ruler for photosensitivity test, and the number of exposure grids is 21 / 41ST.

[0037] 3. Developing: The developing solution is 1% sodium carbonate aqueous solution, the developing temperature is 30°C, the developi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com