Method of utilizing binary zone plate to design diffraction multi-focus element and realize axial direction multi-focus optical path structure

A multi-focus, zone plate technology, used in optical components, optics, instruments, etc., can solve the problem of inability to accurately control the uniformity and quantity of focal energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

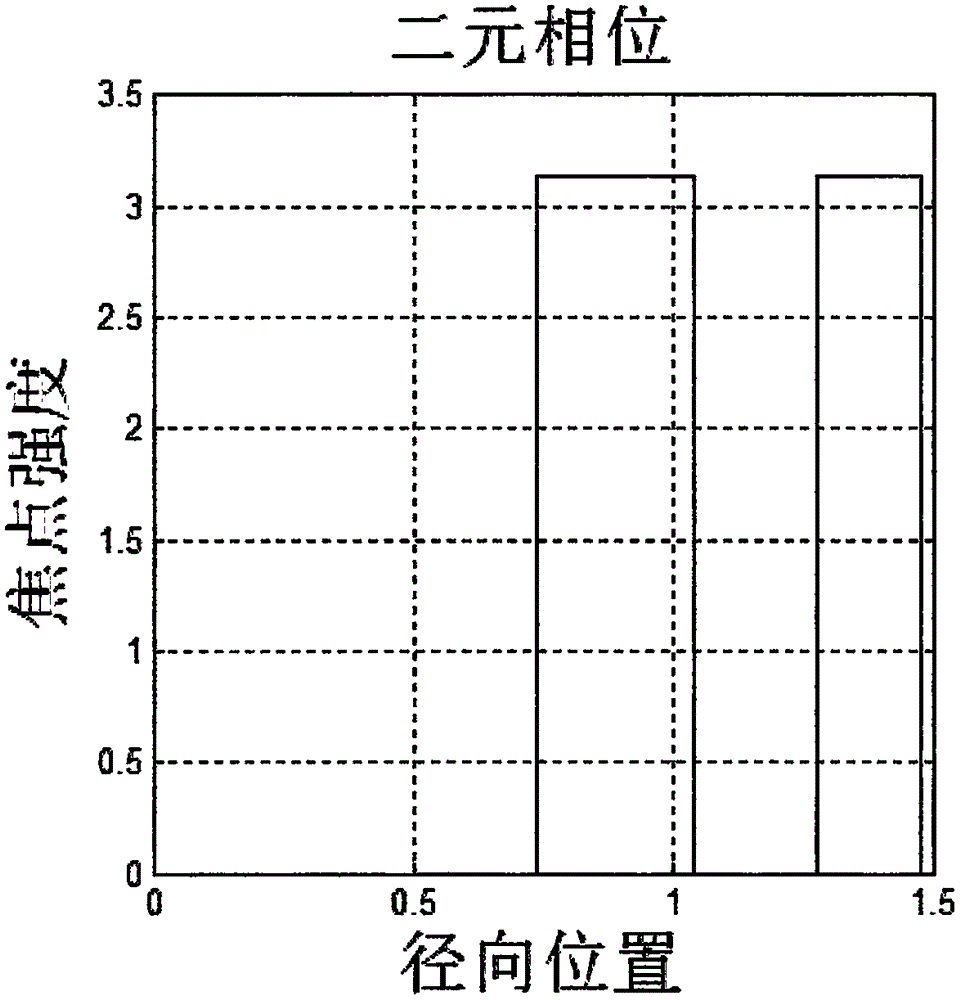

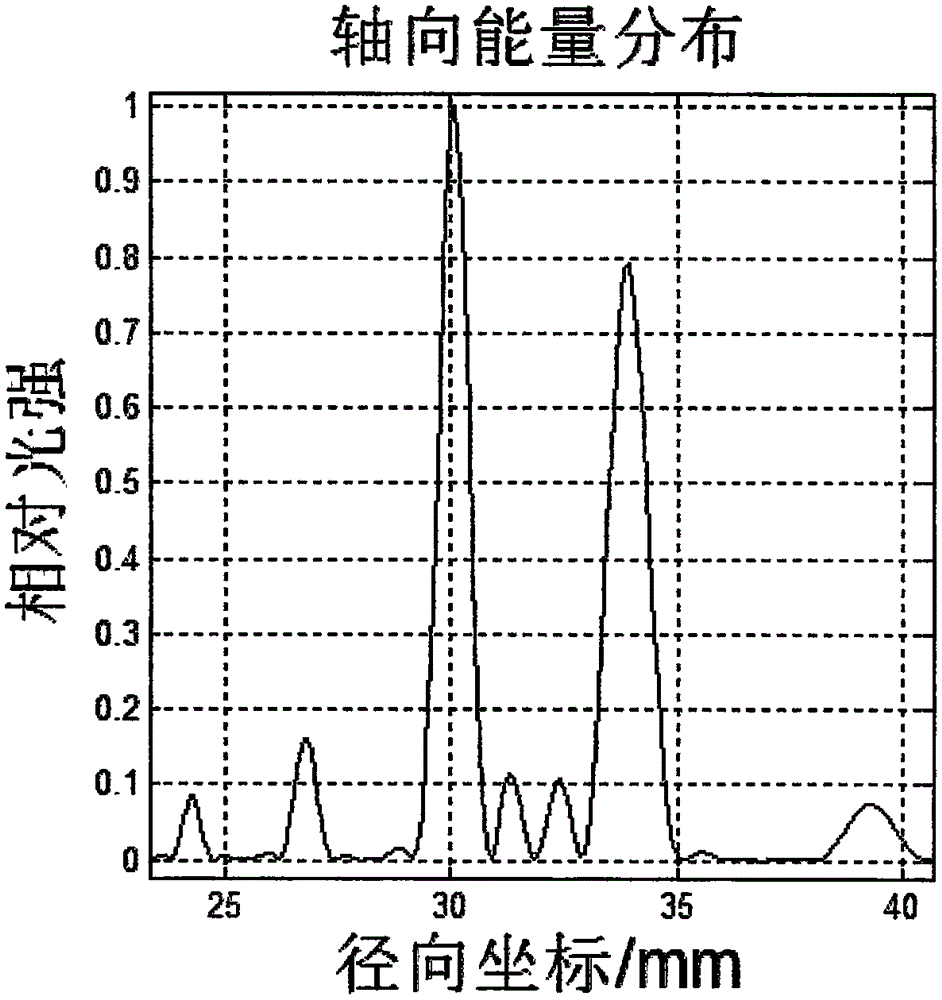

[0022] Example 1 achieves a uniform bifocal element design.

[0023] Incident laser wavelength λ=1.064μm, spot radius R=1.5mm The focal length of the first focal point is f a =30mm, the focal length of the second focal point is f b = 34mm.

[0024] Step 1: Obtain the focal length f of the diffraction element from the focal length of the target focal point 1 , and the focal length of the focusing mirror f 2 .

[0025] The second step: expand and collimate the laser beam to meet the requirements of the diffractive multi-focus element for incident light.

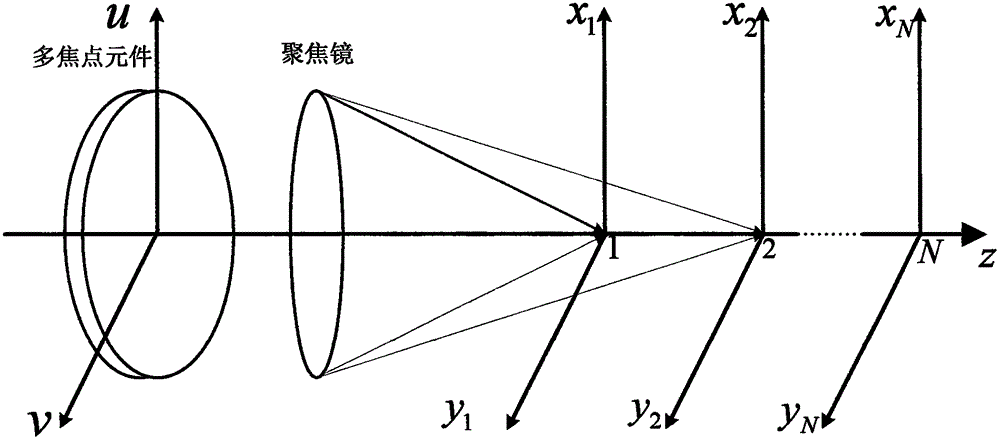

[0026] Step 3: Build the optical path according to the design plan. In the optical path, there are diffractive multi-focus elements and focusing mirrors in sequence along the laser emission direction.

[0027] Step 4: Adjust the position of the image plane along the optical axis, and observe the spot distribution in turn.

[0028] The designed radial binary phase distribution of the multi-focus element is as follows: fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com