A high-speed railway catenary DC ice-melting load temperature monitoring system

A DC deicing and monitoring system technology, applied in radiation pyrometry, measurement devices, optical radiation measurement, etc., can solve the problem of inability to install temperature detection and feedback devices, inability to monitor the ice melting status of the entire line, and increase damage to catenary lines To avoid interference and failure risks, low engineering application cost, and good ice melting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

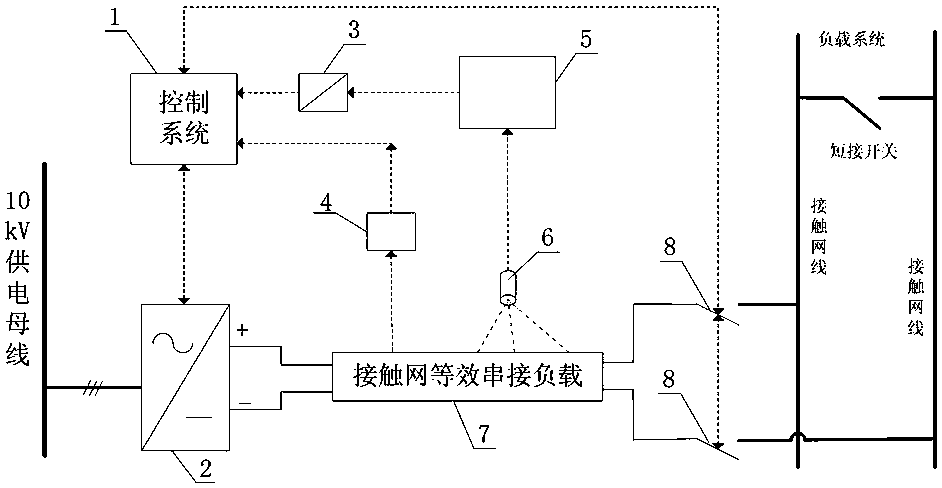

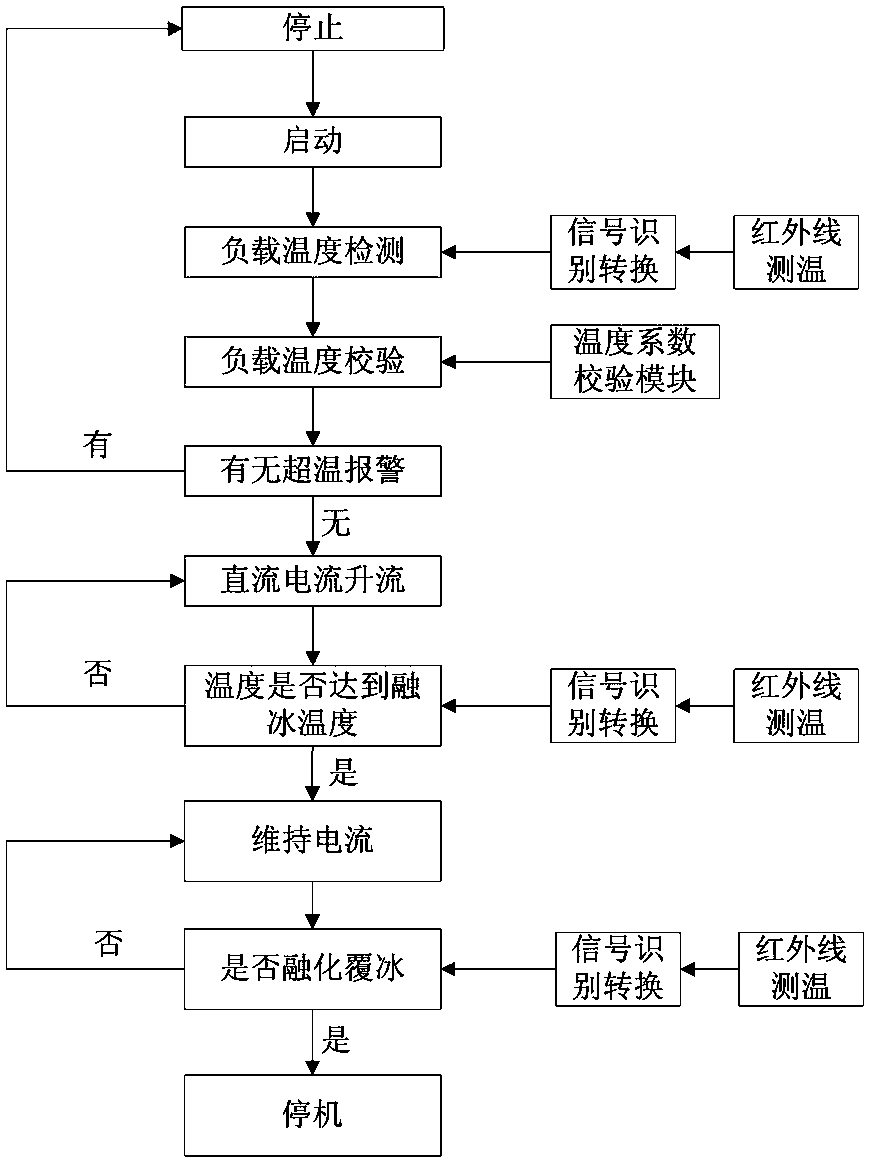

[0020] Such as figure 1 As shown, the high-speed railway catenary DC ice melting load temperature monitoring system of the present invention is used to be used in conjunction with the DC ice melting device body equipment 2 of the high speed railway catenary, and it includes a control system 1, an infrared temperature measuring device 6, a catenary, etc. Effective series connection load 7, temperature coefficient verification and over-temperature protection module 4 and DC ice melting network switch 8, catenary equivalent series connection load 7 is connected to catenary line through DC melting network switch 8; high-precision infrared temperature measurement The device 6 is used to detect the surface temperature of the catenary equivalent series load 7, and transmit the detection signal to the control system 1; wherein, the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com