Connecting assembly and water heater

A technology for connecting components and water heaters, applied in fluid heaters, lighting and heating equipment, etc., can solve problems such as low efficiency and inconvenient assembly, and achieve the effects of simple connection, improved production efficiency, and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

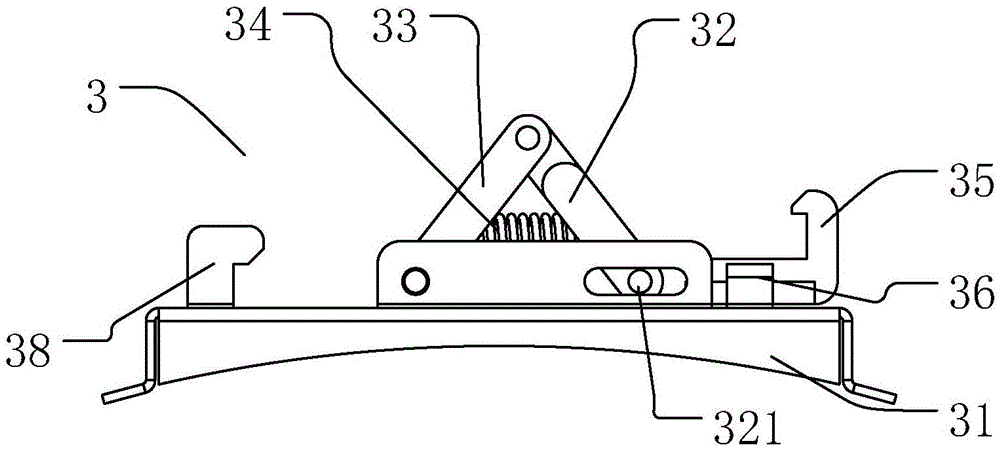

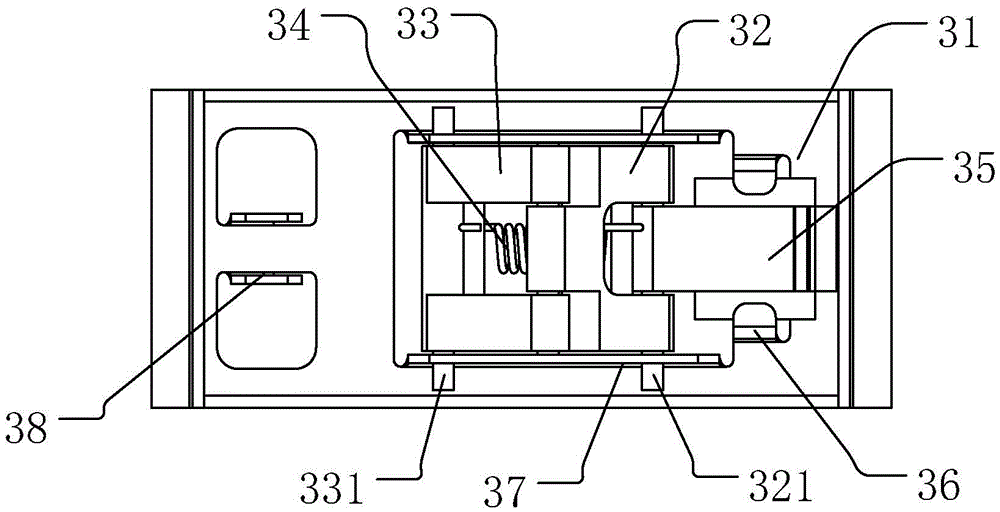

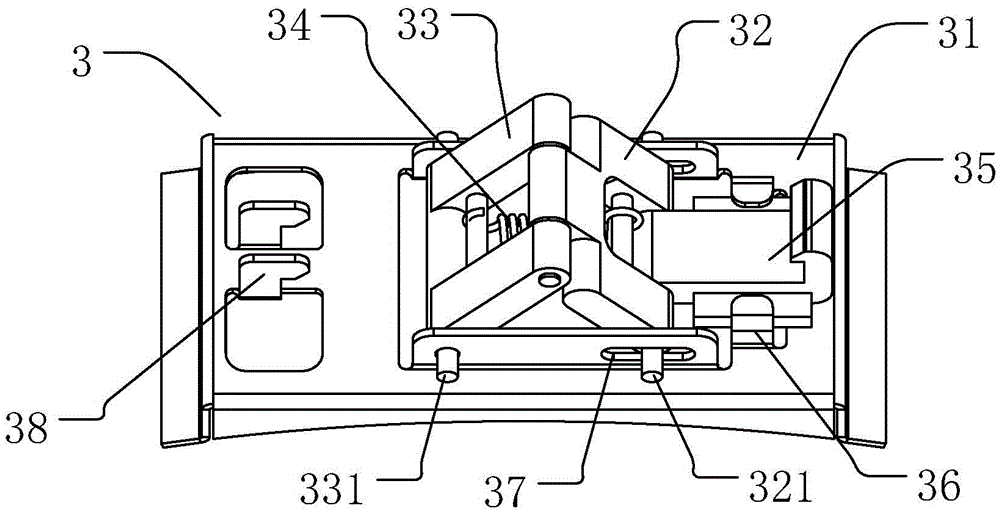

[0029] Embodiment 1 relates to a connection assembly 3, specifically as Figure 1-3 As shown in , it includes a first link 33, a second link 32, an elastic member 34, a first hook 38 and a second hook 35; wherein the first end of the first link 33 and the second link 32 The first end is hinged; the elastic member 34 acts on the first connecting rod 33 and the second connecting rod 32 and makes the first connecting rod 33 and the second connecting rod 32 rotate toward a position close to each other, and the Close means that the angle between the first link 33 and the second link 32 changes from large to small, on the contrary, away from means that the angle between the first link 33 and the second link 32 changes from small to large , Preferably, the angle between the first link 33 and the second link 32 does not exceed 180 degrees. Preferably, the elastic member 34 can be a tension spring or a torsion spring; as shown in the figure, the tension spring used in this embodiment ...

Embodiment approach 2

[0039] Embodiment 2 relates to a water heater, such as Figure 4-7 As shown in , it includes a liner 1 and a microchannel heat exchanger assembly 2 . The microchannel heat exchanger assembly includes two headers 23, and a plurality of flat tubes 22 are arranged between the two headers 23, and the two ends of the flat tubes 23 communicate with the two headers 23 respectively. In the state of use, the microchannel heat exchanger assembly 2 surrounds the outer periphery of the inner container 1 and is fixed on the inner container 1 through the connection assembly 3 in the first embodiment. Its specific connection structure is as Figure 4-7 .

[0040] A connection mechanism is provided on the header 23, the connection mechanism is preferably a pull ring 21, and the number can be one or more. After the microchannel heat exchanger assembly 2 surrounds the inner tank 1, the two flat tubes 23 are arranged adjacent to the surface of the inner tank 1. At this time, the first hook pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com