Damping type pipe clamp

A pipe clamp and anti-vibration ring technology, which is applied in the direction of pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of non-adjustable angle, single function, dead connection, etc., achieve scientific and reasonable structural design, and ensure driving safety , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

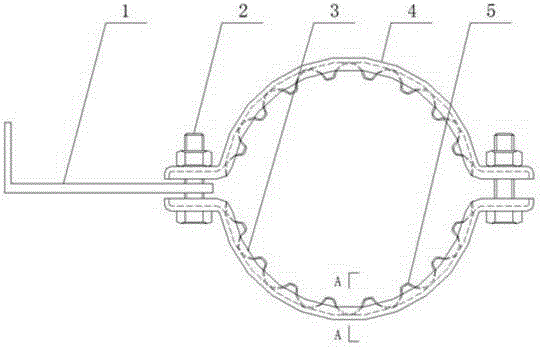

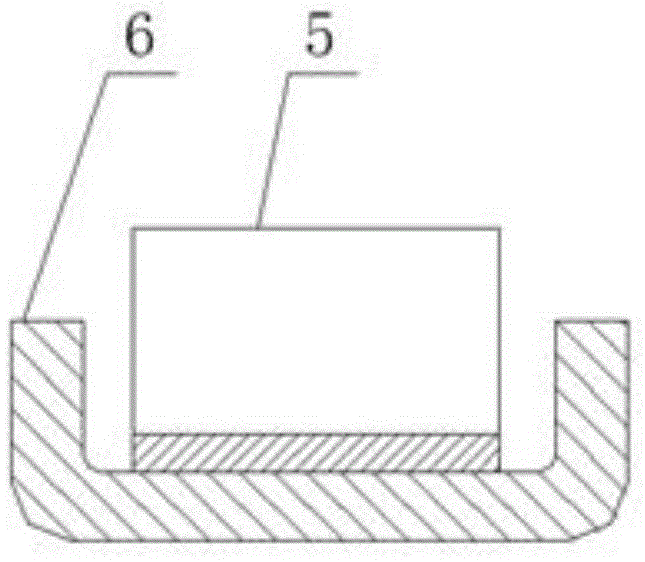

[0016] A shock-absorbing pipe clamp, including a fixed rod 1 and a snap ring, the snap ring is composed of a clip seat 3 and a clip cover 4, the clip seat and the inner surface of the clip cover are installed oppositely, and the two ends are connected by bolts 2. The innovation lies in: a mounting hole is made on the connecting part of the fixed rod, and the fixed rod realizes the flexible connection with the snap ring by fitting the mounting hole on the bolt between the card seat and the card cover, and also includes a shockproof ring 5. The anti-vibration ring is arranged on the inner side of the snap ring.

[0017] The anti-vibration ring is composed of two semi-circular anti-vibration bodies, both of which are wave-shaped, and each anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com