Vortex generator for blade of wind driven generator

A wind turbine and blade vortex technology, which is applied in the direction of wind turbines, wind power generation, engines, etc., can solve the problems of insignificant power generation efficiency improvement, intermittent vortex, and low vortex intensity, so as to improve lift and suppress airflow The effect of separation and vortex airflow stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

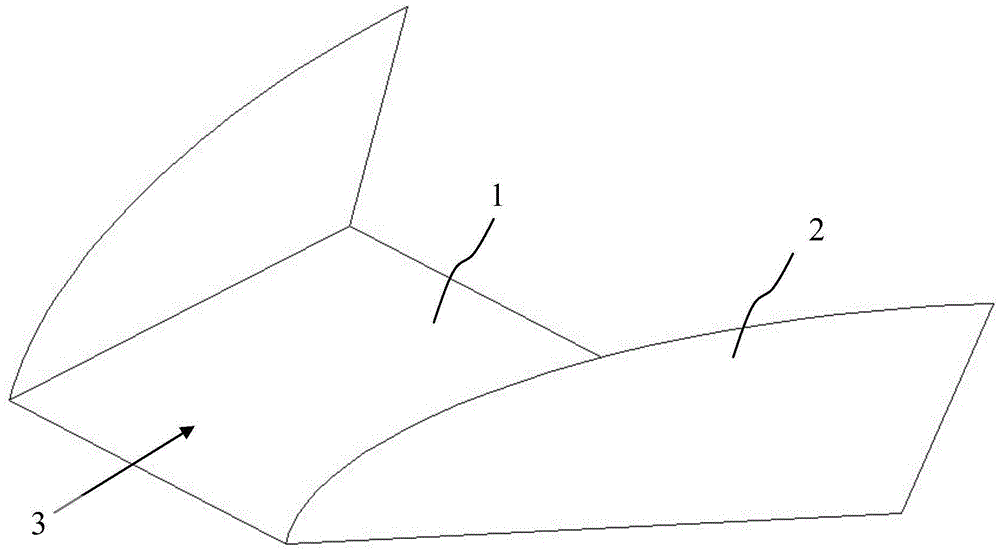

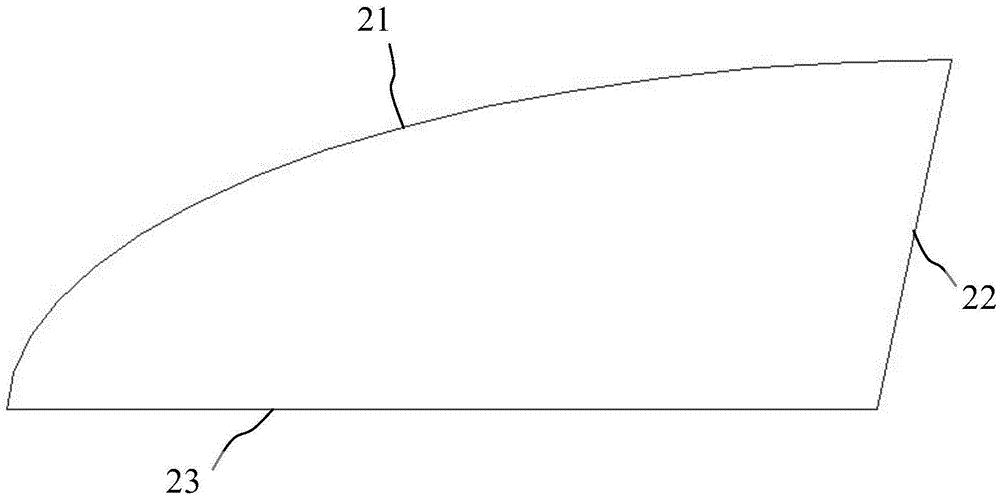

[0021] The wind turbine blade vortex generator of the present embodiment is as figure 1 As shown, all are integral structures made of PC alloy, which include a base 1 and two profiles 2 with the same structure. The base 1 is in the shape of an isosceles trapezoid, including an upper bottom edge at the front end, a lower bottom edge and two waists at the rear end. Profile 2 has 1 / 4 oval side 21, swept back hypotenuse 22 and straight side 23, such as figure 2 As shown, the front end of the straight side 23 and the front end of the 1 / 4 elliptical side 21 intersect to form the front end of the profile 22, and the rear end of the straight side 23 is compared with the bottom end of the swept hypotenuse 22 to form the bottom corner of the rear end of the profile 2, 1 / 4 The rear end of the elliptical side 21 intersects with the top of the swept-back hypotenuse 22 to form the top corner of the rear end of the profile 2 . The two profiles 2 are perpendicular to the base 1 and the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com