Making method of integrated board

A manufacturing method and technology of foamed ceramic plates, applied in chemical instruments and methods, covering/lining, layered products, etc., can solve problems such as poor dimensional stability, uneven surface, poor fire resistance, etc., and achieve good dimensional stability, The surface is bright and smooth, and the effect of fire protection performance guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

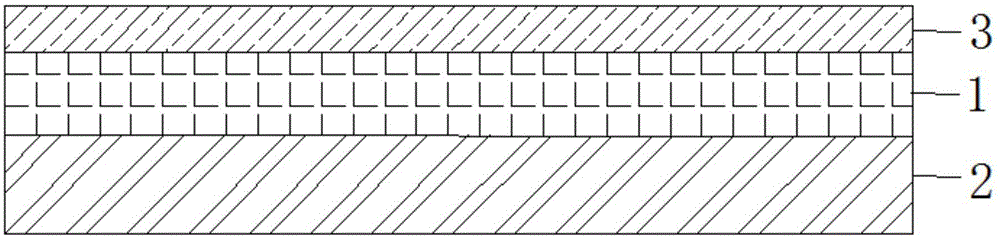

[0027] figure 1 A schematic cross-sectional view of the integrated panel of this embodiment is shown.

[0028] Such as figure 1 As shown, the integrated panel of this embodiment includes a ceramic foam layer 1 , a polyurethane layer 2 and a decorative layer 3 , the polyurethane layer 2 is formed on the back of the ceramic foam layer 1 , and the decorative layer 3 is formed on the front of the ceramic foam layer 1 . The ceramic foam layer 1 and the polyurethane layer 2 constitute an insulating layer, and the thickness of the insulating layer is generally set at 20-30mm, but the thickness of the ceramic foam layer 1 and the polyurethane layer 2 can also be adjusted appropriately according to the climate conditions in the area of use.

[0029] Polyurethane layer 2 adopts hard polyurethane layer. The polyurethane material itself has moisture-proof, water-proof, heat-insulating and heat-insulating properties. , and the coefficient of deformation is small, it is not easy to defo...

no. 2 approach

[0040] figure 2 A schematic cross-sectional view showing an integrated panel according to a second embodiment of the present invention.

[0041] Such as figure 2 As shown, the integrated panel of this embodiment includes a ceramic foam layer 1 , a polyurethane layer 2 and a decorative layer 3 , the polyurethane layer 2 is formed on the back of the ceramic foam layer 1 , and the decorative layer 3 is formed on the front of the ceramic foam layer 1 .

[0042] In addition, an airgel paint layer 4 is also included between the foam ceramic layer 1 and the decoration layer 3, and the foam ceramic layer 1, the polyurethane layer 2 and the airgel paint layer 4 jointly constitute an insulation layer. In this embodiment, the silica airgel coating is used, and the airgel has high strength, high thermal insulation performance and good sound insulation performance.

[0043] As in the first embodiment, a hard polyurethane layer is used for the polyurethane layer 2 .

[0044] The decora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com