Cornice plug-in gutter structure and installation method

A technology for cornices and gutters, which is applied to building structures, roofs, buildings, etc., and can solve problems such as production loss inside the factory building, rainwater entering the inside of the factory building, and gaps at the penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

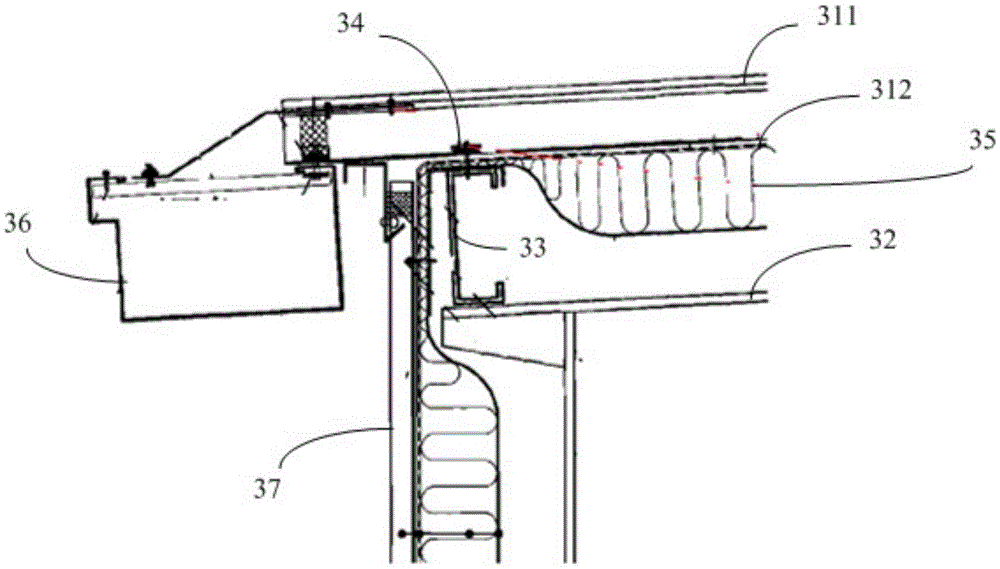

[0054] Figure 4 It is a structural diagram of the gutter structure hanging outside the eaves of the embodiment of the present invention, as Figure 4 As shown, the embodiment of the present invention provides a gutter structure with an external cornice, including:

[0055] The main steel frame 411 is installed and fixed with a purlin bracket 412;

[0056] The eaves purlin 413 is located on the inner side of the wall 42 and is fixed on the purlin bracket 412;

[0057] Screw 43 fixes the thermal insulation layer 415 on the purlin upper end of the cornice purlin 413;

[0058]The eaves bending angle steel 45 is a long trough, and the cross section of the long trough has a left side wall, a right side wall and a top plane; fixed; the left side wall is located on the outside of the wall 42; the top plane is a predetermined distance above the upper end of the purlin; the trough 44 of the roof panel is supported on the top plane, and the screw 43 is located on the top plane. belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com