Clamping plate type reinforcing cage mounting platform

A technology for installing platforms and steel cages, applied in construction, infrastructure engineering, etc., can solve problems such as high construction safety risks, large construction safety risks, and difficult operations, achieve safe and reliable construction conditions, improve construction quality, and avoid human deviations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

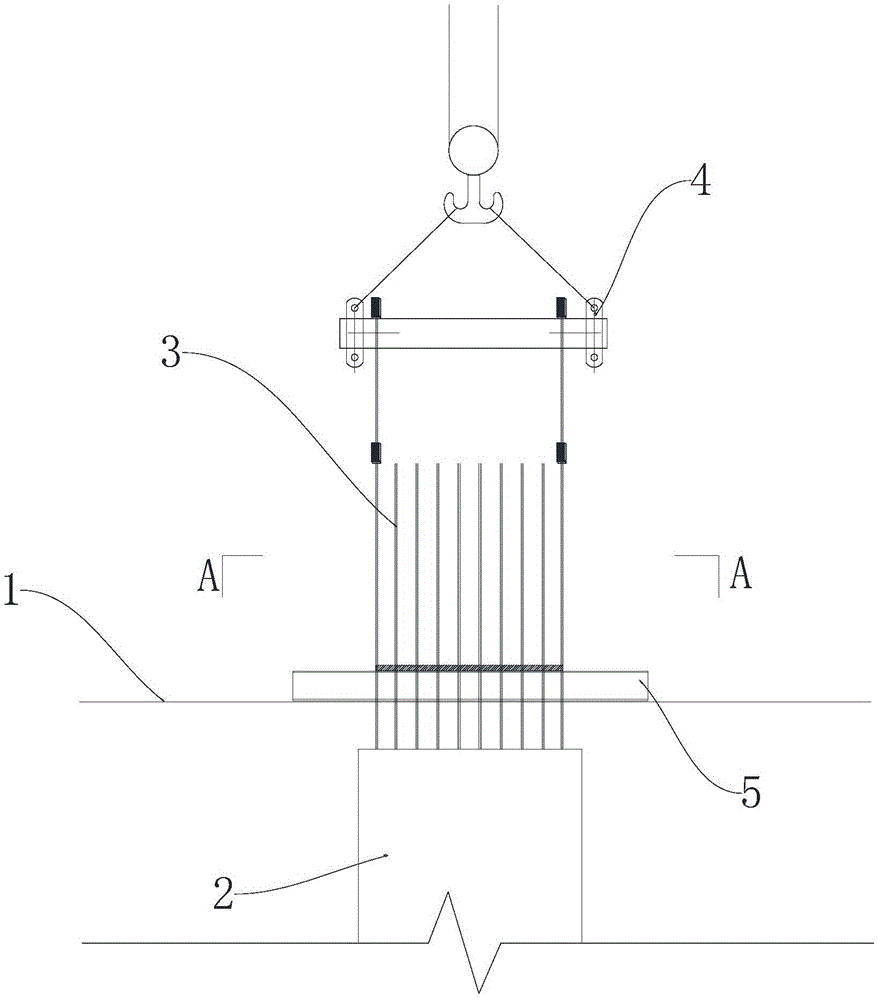

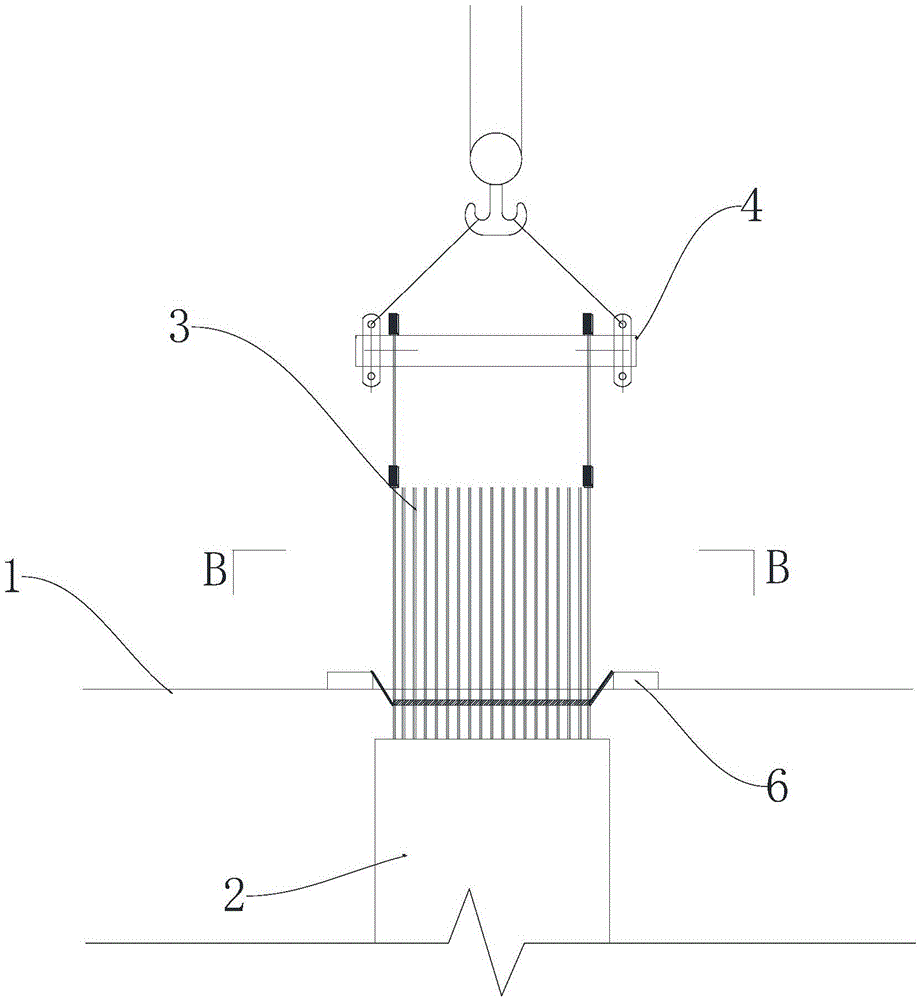

[0044] Clamp type reinforcement cage installation platform

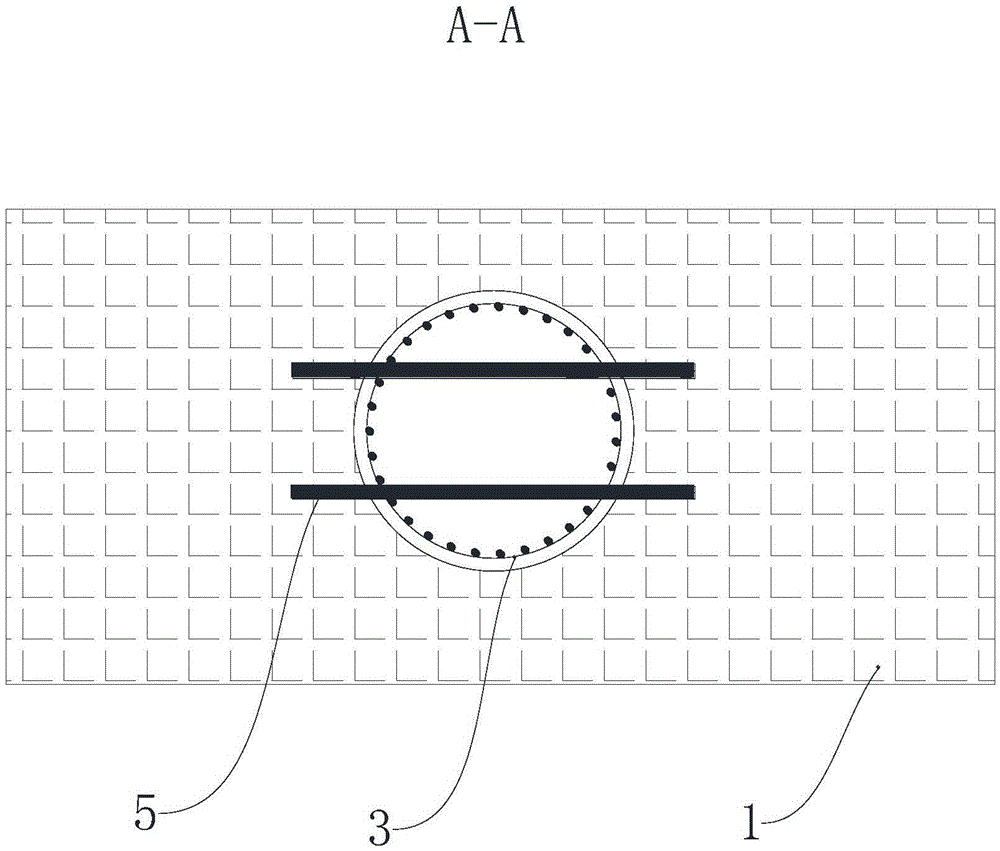

[0045] refer to Figure 5-8 In the present invention, the installation platform 7 of the clasp-type reinforcement cage includes an annular runner platform 71 and a clasp system 72 clamped on the annular runner platform 71 . The clip-type reinforcement cage installation platform 7 is placed on the construction platform 1 of the pile foundation, and is positioned at the corresponding pile foundation gap 11, so that the reinforcement cage 3 can be assembled and docked at the pile foundation gap 11.

[0046] refer to Figure 6 and 7, the annular runner platform 71 includes a main bracket 711 arranged around the pile foundation runner 11 and an annular plate 712 protrudingly installed on the main bracket 711 . The main support 711 includes a pair of first skeletons 7111 parallel to each other, a pair of second skeletons 7112 spanning between the first skeletons 7111, and the first skeletons 7111 and the second skeleton...

Embodiment 2

[0055] suspension system

[0056] refer to Figure 5 , the present invention lifts and lowers the reinforcement cage and its segments through the suspension system 4 . The suspension system 4 includes a hanger 41 and a hanging bar 42 whose top end is anchored to the hanger 41 . The hanging bars 42 are spliced by multiple sections of steel bars, wherein the steel bars at the joints are tapped with external threads, and two adjacent sections of steel bars are connected by a steel bar extension connecting sleeve provided with internal threads. Further, the first section 421 of the hanging bar 42 is composed of two sections of steel bars, wherein the section anchored with the hanger 42 is the non-working section 4211, and the section anchored with the reinforcement cage 3 is the working section .

[0057] refer to Figure 14 , the suspension system 4 also includes a sand barrel 43 through the center drop frame, which is used to place the hanging ribs 42 passed through the up...

Embodiment 3

[0059] Installation method of super long and super heavy steel cage

[0060] refer to Figure 5 and Figures 15-19 , the installation method of the super-long super-heavy reinforcement cage of the present invention comprises the following steps:

[0061] 1. Install the steel cage installation platform

[0062] For large reinforcement cages, the assembly of reinforcement cages is generally carried out above or near the place where the reinforcement columns are installed, and the assembled reinforcement cages are lowered into the pre-placed reinforcement cage casing 2, so it can be installed according to the preset The position of the casing determines the placement position of the clamped steel cage installation platform 7 . Specifically, according to the central position of the pile foundation dragon mouth 11, the axis of the pile foundation is staked out, and the position of the central axis of the pre-assembled clamped steel cage installation platform 7 coincides with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com