Drill detection device used for qualitative detection of composition and distribution of soil layer

A technology of brazing and soil layer, which is applied in the field of basic soil survey, construction, infrastructure engineering, etc., can solve the problems of unnecessary, inconvenient to carry, inconvenient to carry equipment, etc., to reduce damage and impact, and to be easy to carry Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained below in conjunction with specific embodiments and accompanying drawings.

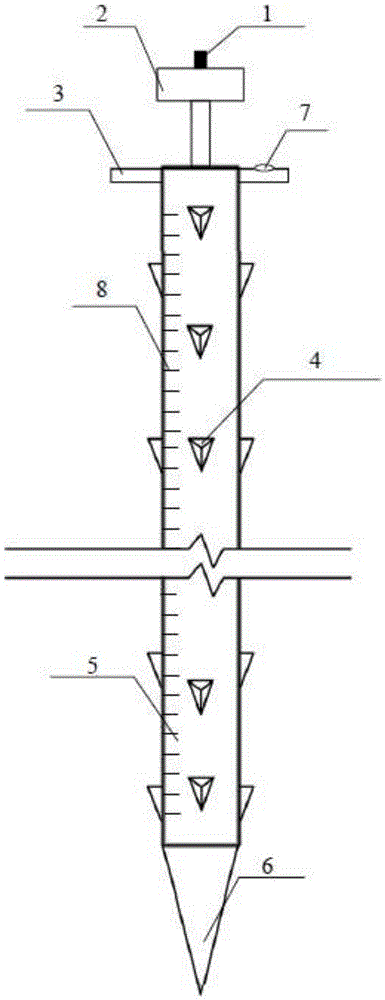

[0022] see figure 1 , the present invention includes a hollow drill rod 5, one end of the hollow drill rod 5 is fixedly provided with a thruster 2, the thruster 2 is a circular or rectangular pressing plate convenient for the operator to apply force, the thruster 2 is made of steel or iron, and The circular surface or rectangular surface is perpendicular to the hollow drill rod 5; the other end of the hollow drill rod 5 is fixedly provided with a tip 6 that is convenient to be pressed into the soil, and the tip 6 is set in a conical shape, and the hollow drill rod 5 is provided with a pressing rod. The barb 4 is arranged on the pressure rod, and the barb 4 is arranged in the shape of a triangular pyramid. The upper surface of the triangular pyramid is provided with a groove for taking soil, and the side wall of the hollow drill rod 5 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com