Pin riveting press

A pin and riveting technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of long pressing time, affecting component assembly, low efficiency, etc., to improve efficiency, ensure safety, and overcome limitations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

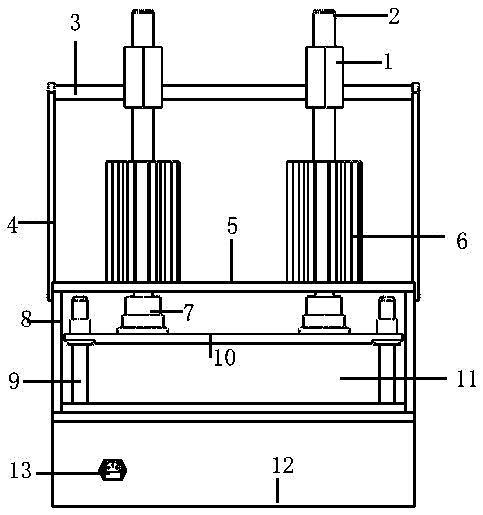

[0014] The figure is a preferred embodiment of the present invention, and the present invention will be further described below in conjunction with the accompanying drawings.

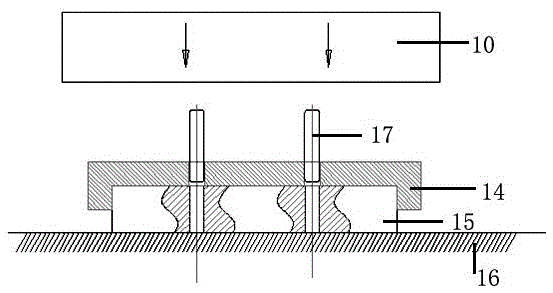

[0015] according to Figure 1-Figure 2 , a pin riveting press, comprising a frame structure composed of a horizontally arranged upper support plate 3, vertically arranged two side plates 4 and a horizontally arranged upper pressing plate 5, characterized in that it also includes a Cylinder 6 moving up and down, two vertical connecting plates 8 communicated with side plate 4, the base plate 16 to be pressed horizontally arranged to connect two connecting plates, described cylinder 6 ends are provided with upper pressing seat 7, and pressing The seat is pressed together with the pin press-in positioning part 11, and the upper press seat is fixed on the upper mounting plate 10; the connecting plate, the bottom plate to be pressed and the upper mounting plate are surrounded by a pin pressing-in positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com