Embroidery making methods, embroidery, fabrics, crafts and clothing

A production method and embroidery technology, applied in the field of clothing, handicraft embroidery, and fabrics, can solve the problems of high training costs for enterprises, hard hand feeling of embroidery products, and high product scrap rate, so as to achieve good hand feeling and visual sensory effects, and improve Aesthetics and comfort, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

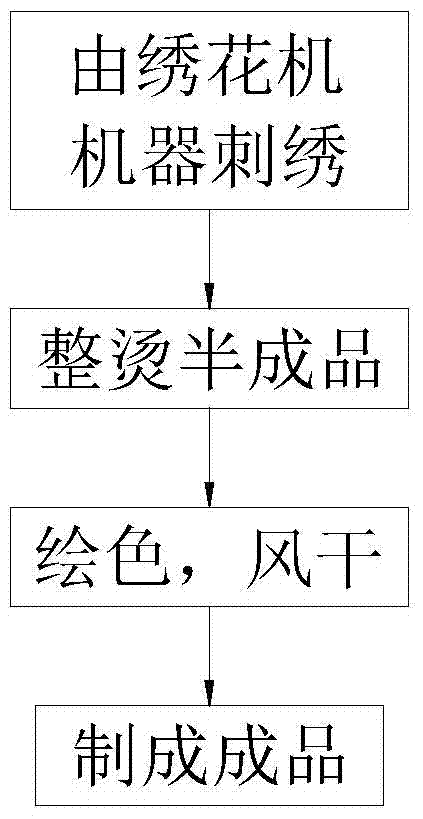

[0055] figure 1 It is the process flow diagram of embodiment 1 of the present invention;

[0056] A method for making embroidery, comprising the following steps in sequence:

[0057] SD, the machine embroidery operation is implemented by the embroidery machine;

[0058] SE, carry out ironing operation on the semi-finished products after embroidery; after ironing operation, carry out air-drying operation on embroidery

[0059] SG, finished fabrics or garments or handicrafts.

[0060] Embroidery by embroidery machine can reduce the labor load of workers, reduce the labor consumption of embroidery production, improve production efficiency and reduce production cost. Moreover, the embroidery is performed by an embroidery machine, the product has high repeatability and the quality is easy to control.

[0061] Air-drying can also increase the manufacturing speed of finished products and shorten the processing cycle of a single product.

Embodiment 2

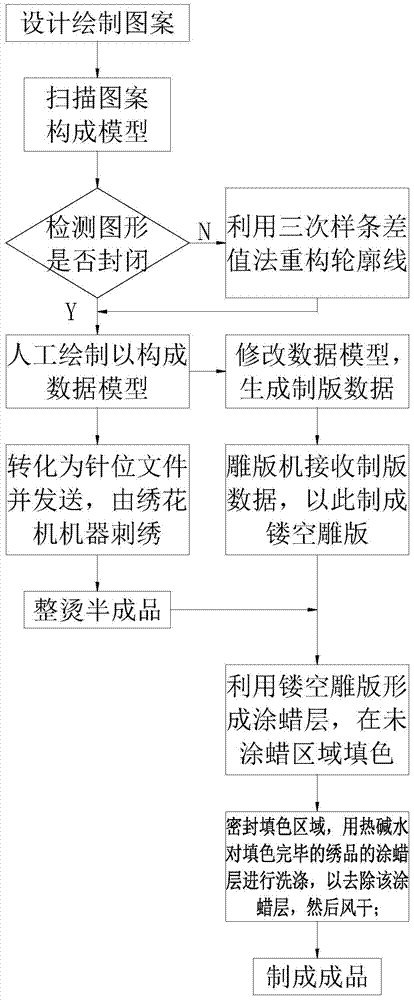

[0063] figure 2 It is the process flow chart of the embroidery production method of the embodiment of the present invention 2;

[0064] A method for making embroidery, comprising the following steps in sequence:

[0065] SA, choose the fabric of the embroidery, design and draw the preliminary pattern of the embroidery;

[0066] SB. Scanning the designed embroidery preliminary pattern, manually using computer-aided design software to draw the supplementary pattern of embroidery, and then extracting the contour features of the pattern, and storing them in the control point array of the contour class, and checking the closedness of the contour, If it is not closed, copy the first control point and insert it at the end of the control point array to make it a closed figure, use the cubic spline interpolation method to reconstruct the contour line, and insert the control points of the contour class In the group, the data model is obtained;

[0067] SC, convert the data model int...

Embodiment 3

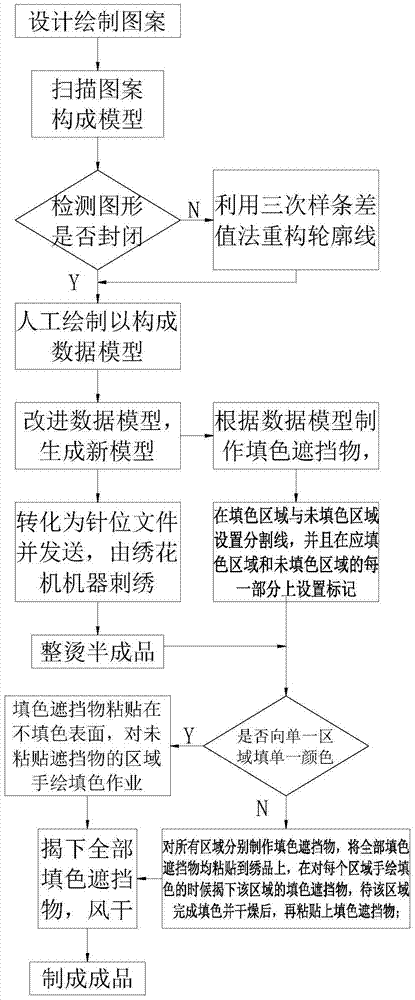

[0083] image 3 It is the process flow chart of the embroidery production method of the embodiment of the present invention 3,

[0084] A method for making embroidery, comprising the following steps in sequence:

[0085] SA, choose the fabric of the embroidery, design and draw the preliminary pattern of the embroidery;

[0086] SB. Scanning the designed embroidery preliminary pattern, manually using computer-aided design software to draw the supplementary pattern of embroidery, and then extracting the contour features of the pattern, and storing them in the control point array of the contour class, and checking the closedness of the contour, If it is not closed, copy the first control point and insert it at the end of the control point array to make it a closed figure, use the cubic spline interpolation method to reconstruct the contour line, and insert the control points of the contour class In the group, the data model is obtained;

[0087] SC, convert the data model into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com