Laser template polishing clamp

A polishing fixture and laser template technology, applied in the electrolysis process, electrolysis components and other directions, can solve the problems of low production efficiency, long locking or loosening operation time, etc., and achieve the effect of high production efficiency, short operation time and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

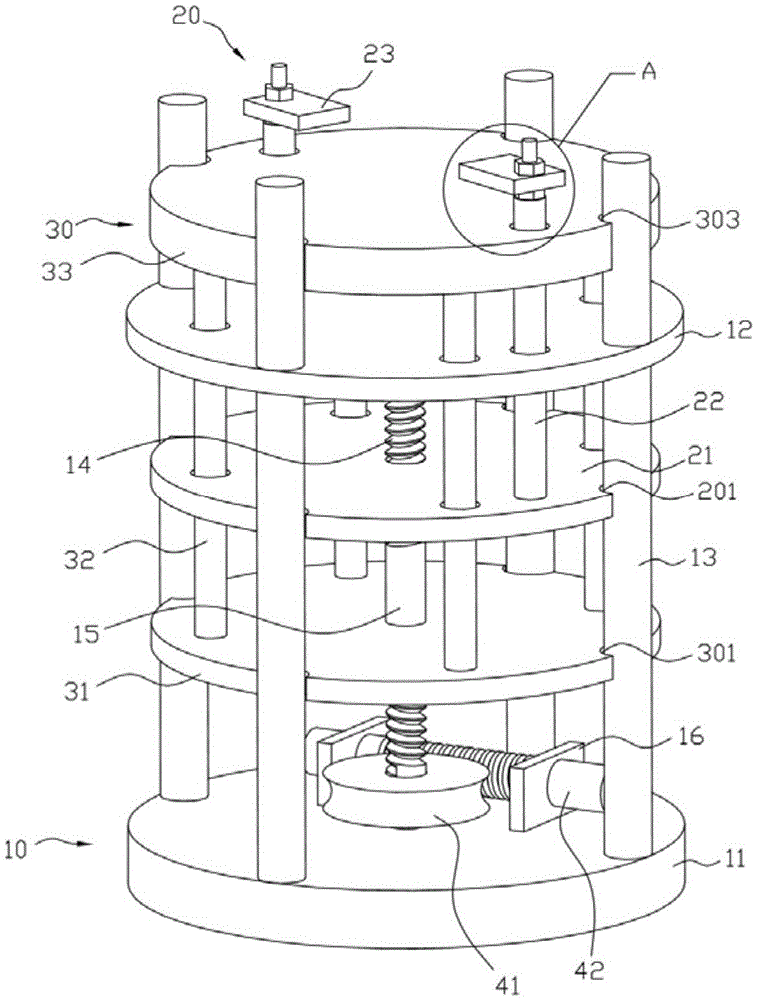

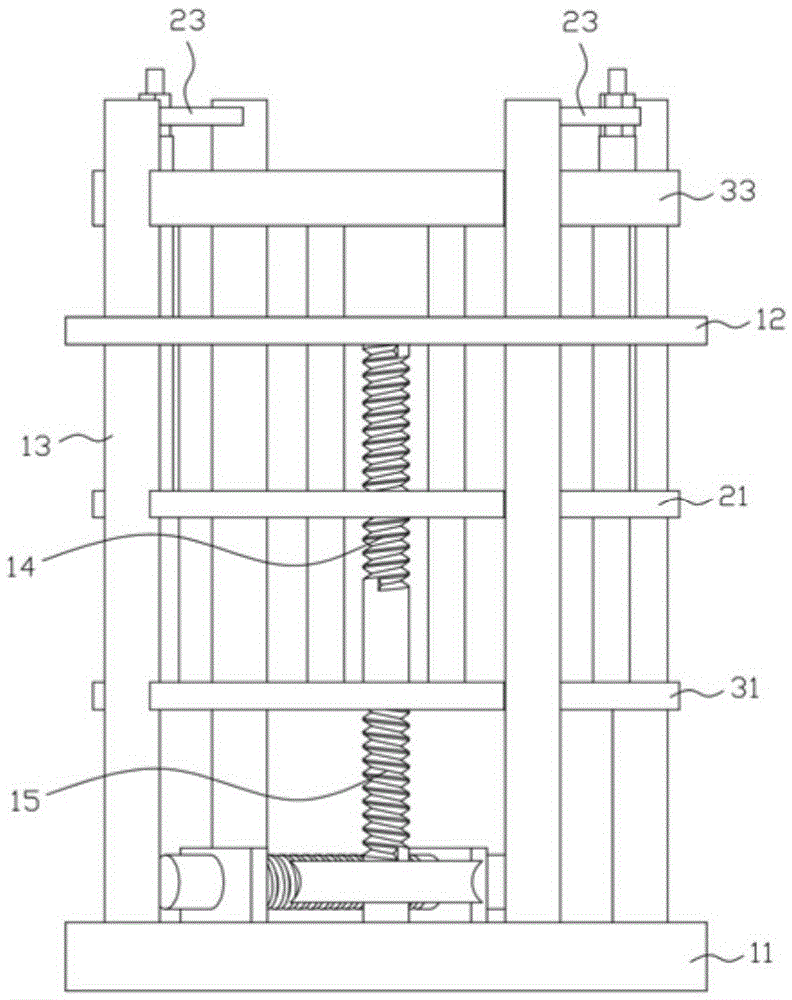

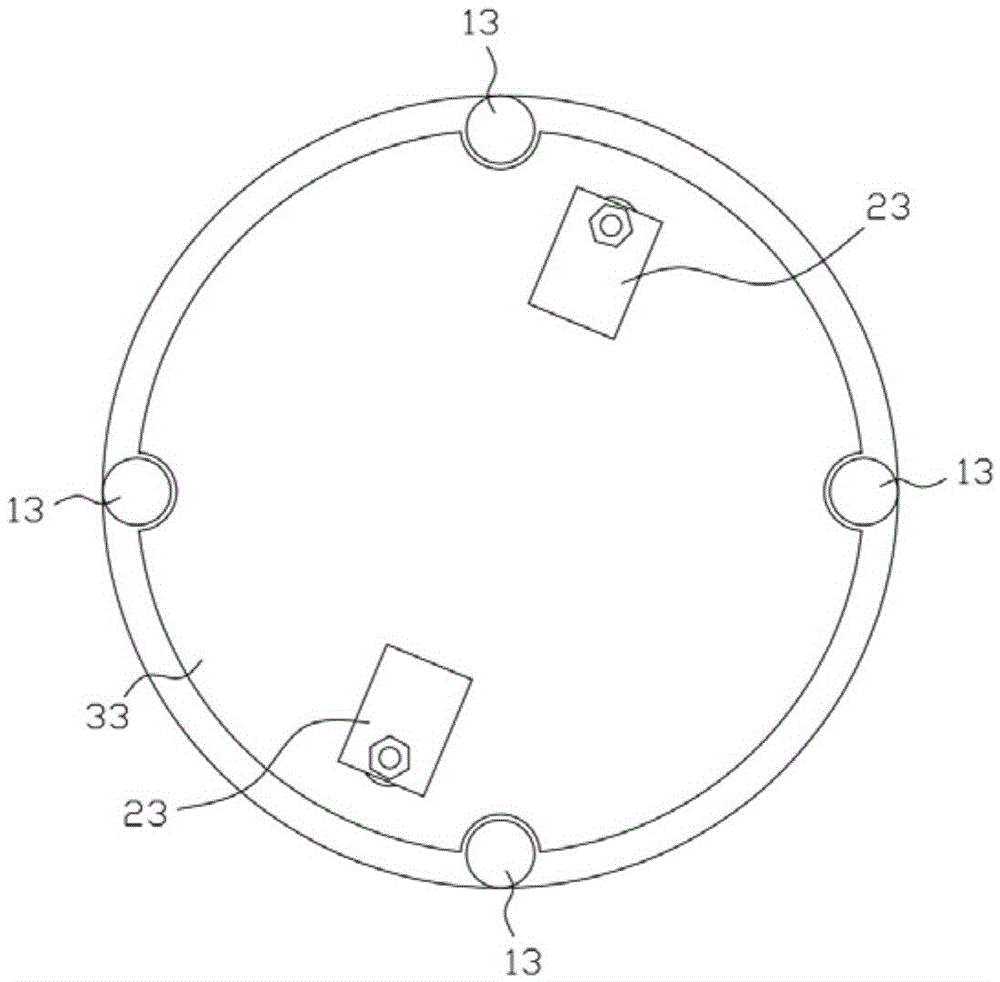

[0029] combine Figure 1 to Figure 3 , a laser template polishing fixture, including a bracket body 10, a locking body 20, and a fixing seat body 30.

[0030] Such as figure 1 , the support body 10 includes a base 11, a support plate 12, and a pillar 13; the pillar is vertically arranged on the base, and the support plate is horizontally arranged on the pillar.

[0031] Such as figure 1 , the locking body 20 includes a first lift chassis 21, a pair of first guide columns 22, and a locking block 23; the first lift chassis provides a first guide notch 201, and the first guide notch and the pillar Sliding fit; the pair of first guide posts are vertically arranged on the first lifting chassis, a pair of first guide holes are opened on the support plate, and a pair of first guide posts are matched in a pair of one-to-one manner. In the first guide hole; the locking block is installed on the top of the first guide post.

[0032] In the above-mentioned locking body 20, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com