Cathode arc ion plating magnetic field adjustment device

An adjustment device and cathodic arc technology, which is applied in ion implantation plating, sputtering plating, vacuum evaporation plating, etc., can solve the problems of threatening the personal safety of coating personnel and affecting the quality of coating, so as to achieve good coating effect and improve the coating quality. Layer performance, the effect of maintaining the consistency of the magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

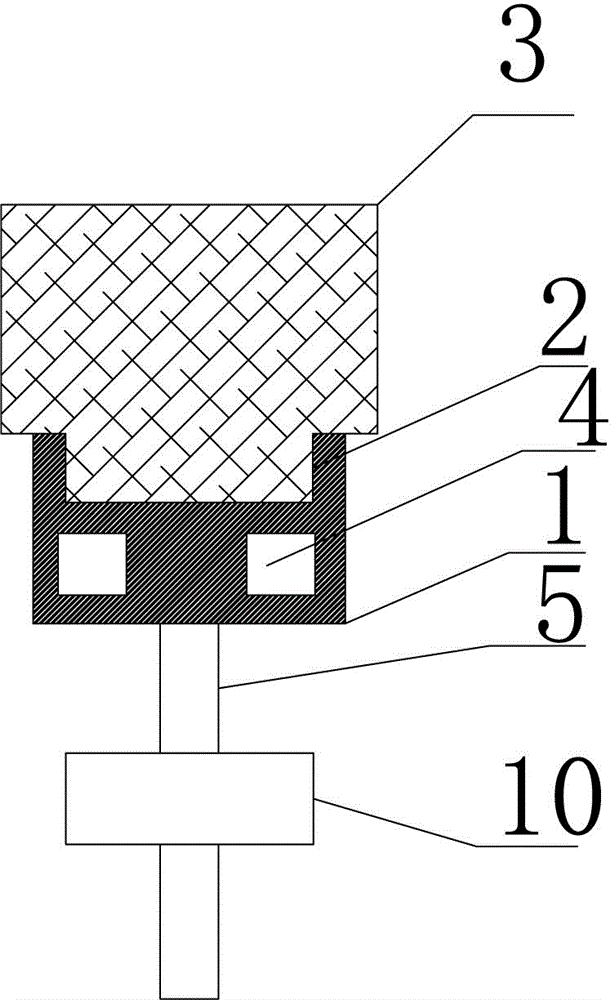

[0017] Such as figure 1 Among them, a magnetic field adjustment device for cathode arc, a cathode target seat 1 is provided in the PVD coating machine housing, a groove 2 is provided on the upper surface of the cathode target seat 1, a target material 3 is arranged in the groove 2, and a cathode target seat 1 is provided A waterway 4 is provided, and the adjustment device includes a screw 5 arranged on the lower surface of the cathode target base 1. The magnet device is arranged on the screw 5 and can move along the screw 5, and the screw 5 is provided with a length scale;

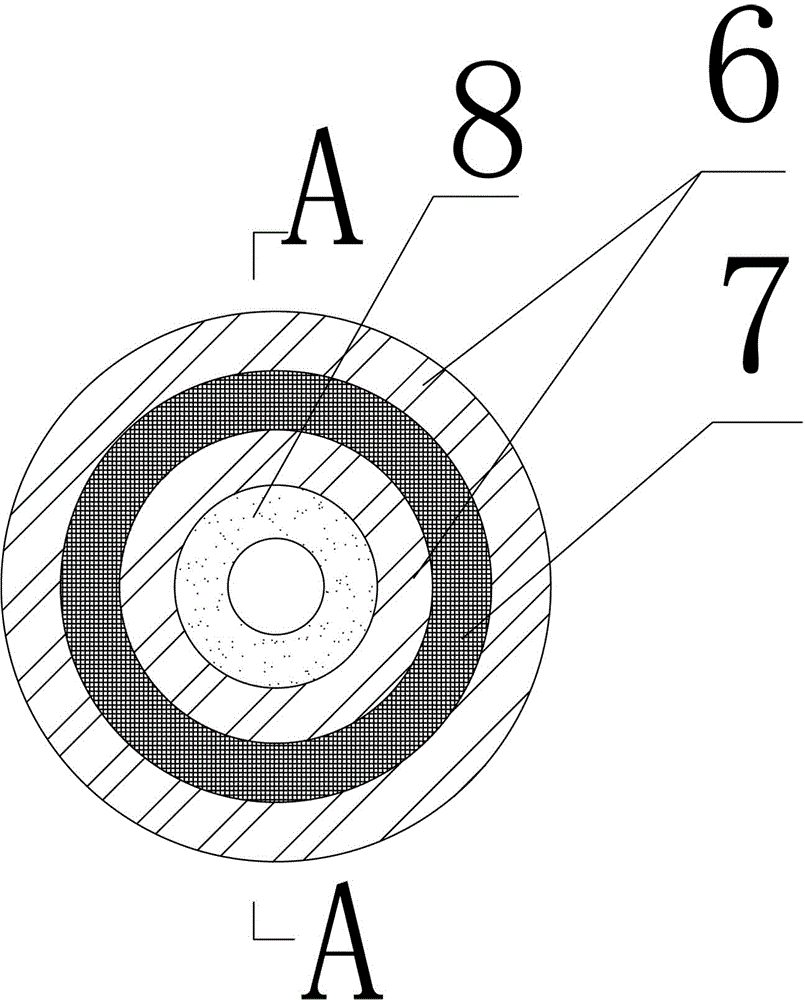

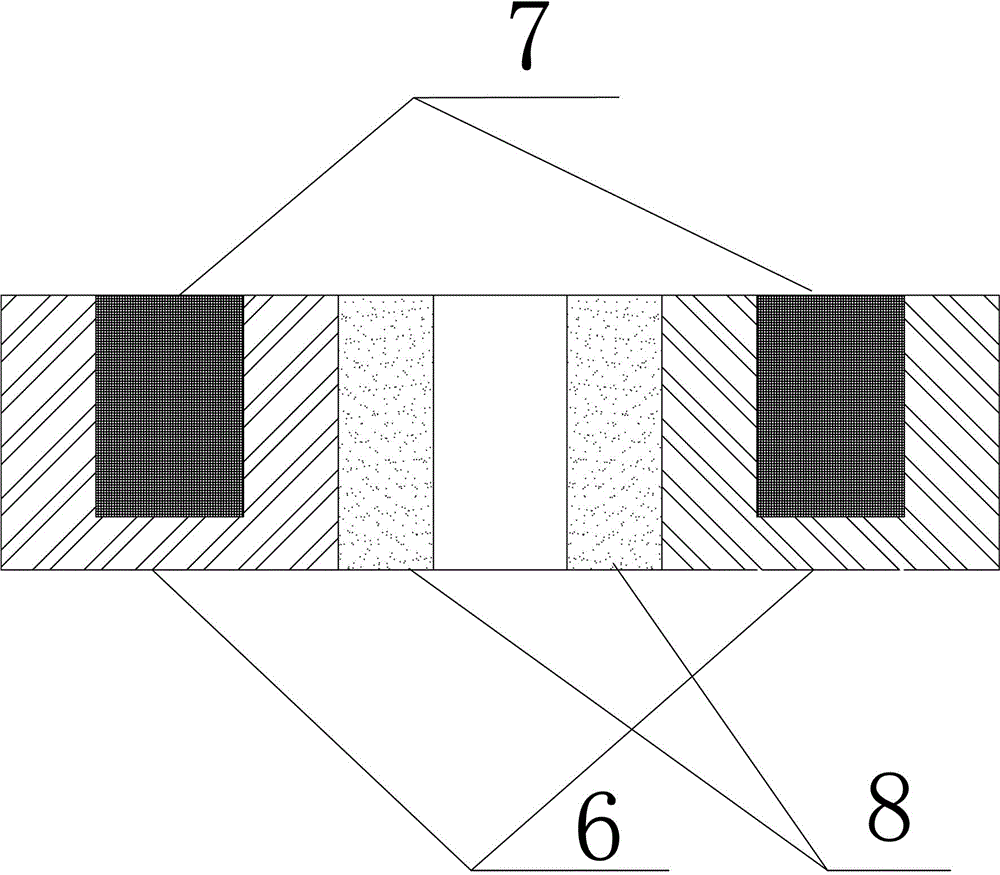

[0018] Such as figure 2 , image 3 Among them, the magnet device 10 includes a U-shaped stainless steel ring 6 in cross section, a permanent magnet 7 is arranged in the U-shaped groove of the stainless steel ring 6, and a polytetrafluoroethylene layer 8 is arranged on the central hole wall of the stainless steel ring 6, The surface of the polytetrafluoro layer 8 has threads to engage with the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com