Metal melting protective agent with chloride as body and preparing method of metal melting protective agent

A metal melting and chloride technology, applied in the field of metal melting protective agent, can solve the problems of incomplete unification and achieve the effects of reducing production costs, saving lead and lead alloys, and obvious social and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

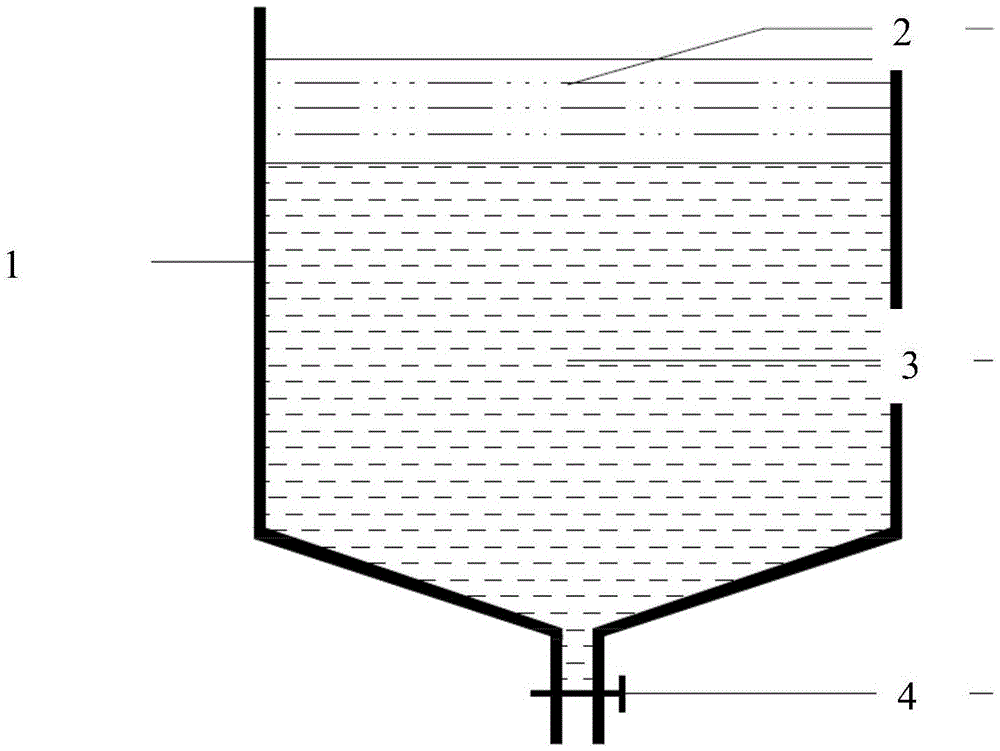

Image

Examples

Embodiment 1

[0030] This embodiment provides a protective agent for molten lead or lead alloy and a preparation method thereof. The following three components are implemented according to mass percentage: 30% to 70% of sodium chloride, 20% to 60% of potassium chloride, and 1 %~20%, the specific implementation ratio of the three substances can be: sodium chloride: potassium chloride: lithium chloride=51:43:6 (mass percentage). During the preparation process, first weigh each component, add it into a mixer, and stir it fully; then use the static melting method to put the above-mentioned uniformly mixed mixture into a high-temperature-resistant container, and heat it to 600-700°C in a high-temperature furnace , constant temperature melting for 3 to 4 hours; then the above molten mixture is naturally cooled, crushed, dried and packaged to obtain the protective agent.

Embodiment 2

[0032] This embodiment provides another protective agent for molten lead or lead alloy and its preparation method. The following 4 components are implemented by mass percentage: 30% to 70% of sodium chloride, 20% to 60% of potassium chloride, lithium chloride 1% to 20%, sodium carbonate 0.1% to 5%. In the preparation process, firstly, the protective agent and sodium carbonate prepared in Example 1 were added into the mixer in a mass ratio of 100:1, and fully stirred evenly; then the static melting method was used to put the above-mentioned uniformly mixed mixture into the Put it in a high-temperature container, heat it to 450-550°C in a high-temperature furnace, and melt it at a constant temperature for 1-2 hours; the above-mentioned molten mixture is naturally cooled, crushed, dried, and packaged to obtain the protective agent.

Embodiment 3

[0034] This embodiment provides another protective agent for molten lead or lead alloy and its preparation method. The following 4 components are implemented by mass percentage: 30% to 70% of sodium chloride, 20% to 60% of potassium chloride, lithium chloride 1% to 20%, potassium carbonate 0.1% to 5%. In the preparation process, firstly, the protective agent and potassium carbonate prepared in Example 1 were added into the blender according to the mass ratio of 100:1, and fully stirred evenly; then the static melting method was used to put the above-mentioned uniformly mixed mixture into the Put it in a high-temperature container, heat it to 450-550°C in a high-temperature furnace, and melt it at a constant temperature for 1-2 hours; the above-mentioned molten mixture is naturally cooled, crushed, dried, and packaged to obtain the protective agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com