A tower bottom scraper for a high-tower granulation device

A high-tower granulation and scraper technology, which is applied to fertilization devices, fertilizer mixtures, and methods for granulating raw materials, can solve the problems of large screw conveyor loads, high power consumption, and sticky arms, and achieve The material is collected thoroughly, the material is not easy to melt into water, and the effect of preventing the accumulation of material in the cone bucket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

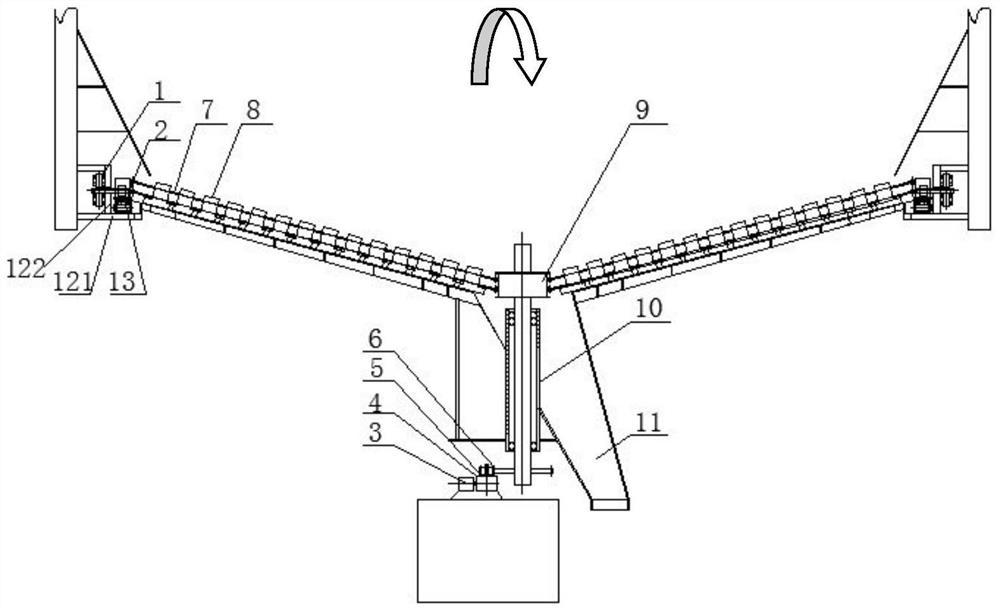

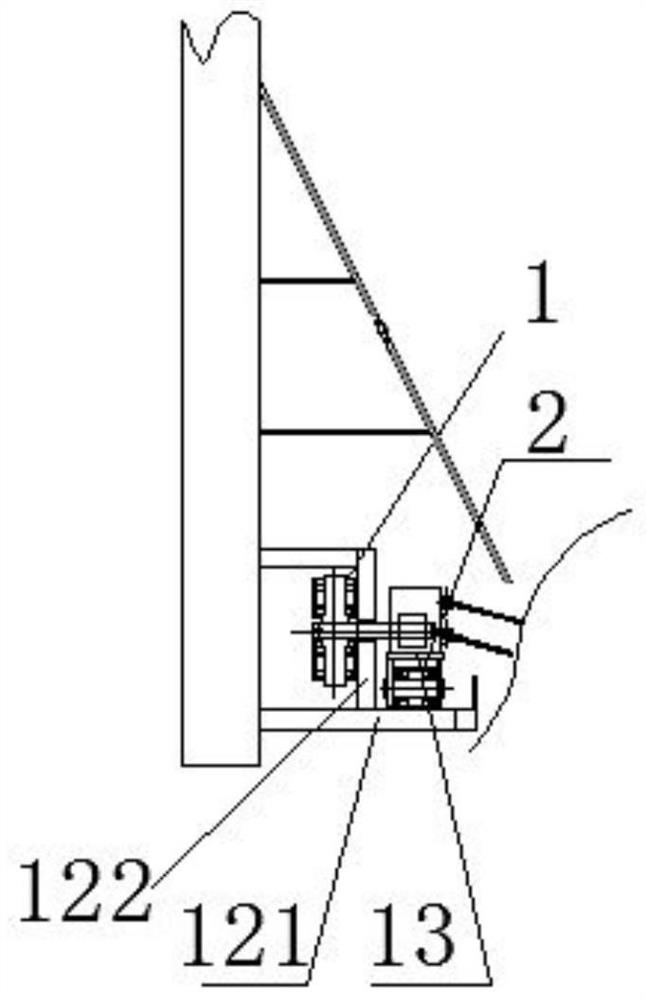

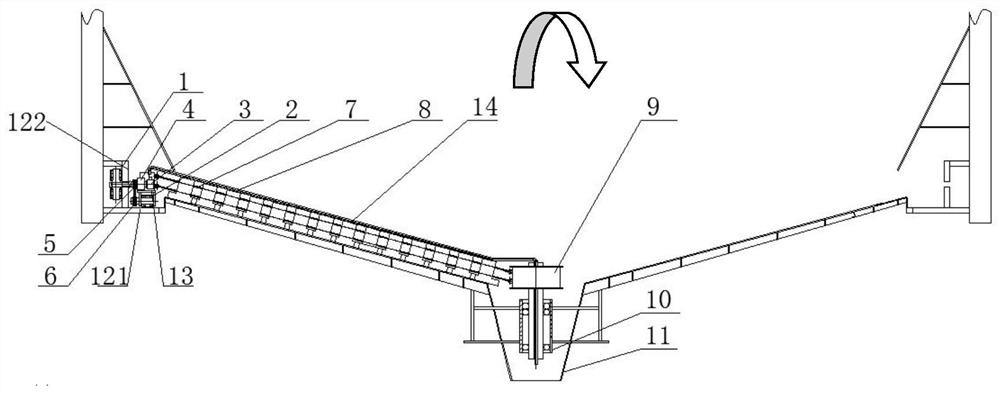

[0036] Such asfigure 1 Or as shown in 3, a specific embodiment of the present invention: a scraper at the bottom of a high tower granulation device, including a high tower granulation cone bucket and a scraper body provided with a feeding port 11, the scraper The body is installed on the upper surface of the high-tower granulation cone. The scraper includes a power end, a rotating end with an outer circumferential track, a scraper arm and a rotating support 9 with a bearing box 10. The scraper arm and the rotating The support 9 is connected; the power end is set at one end and drives the rotating support 9 to rotate so as to drive the scraper arm to rotate on the upper surface of the high tower granulation cone; the rotating end is installed on the outer circumferential track of the high tower granulation cone .

[0037] Preferably, the scraper arm of the scraper consists of a flexible rope 7 and a scraper 8 , one or more flexible ropes 7 are connected to the scraper 8 , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com