Method for synthesizing rare-earth containing MFI zeolite

A synthesis method and rare earth technology, applied in the field of synthesis of MFI zeolite, can solve the problem of low rare earth content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 2 grams of Magadiite with a silicon-aluminum ratio of 200 (molar ratio) are mixed with 30 milliliters of 1mol / L La(NO 3 ) 3 solution, the mixture is stirred at room temperature for 18 hours, then washed, separated and dried to obtain a mixture containing La Magadiite material.

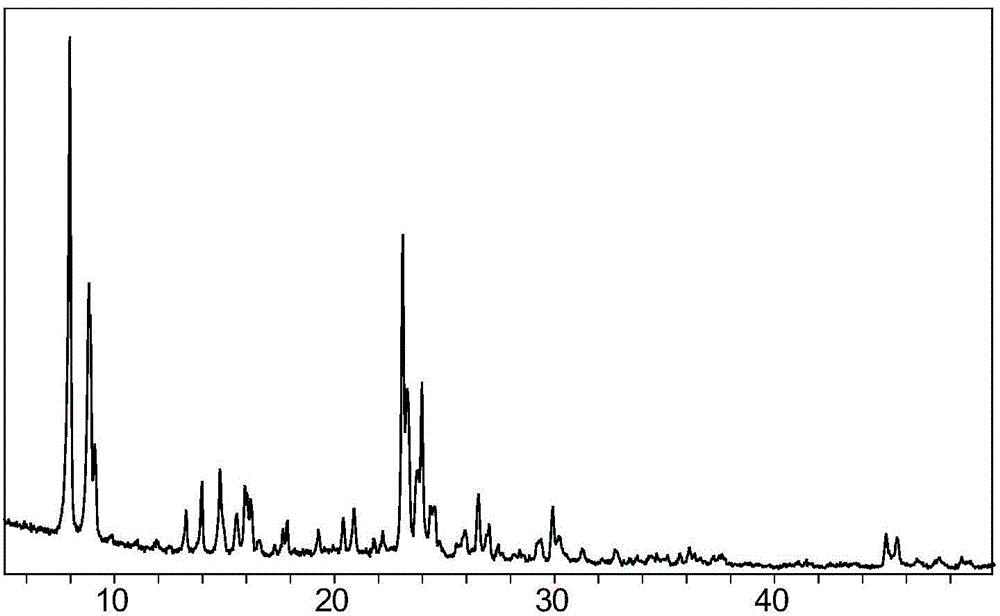

[0030]Mix 1.8 grams of the above-mentioned Magadiite material containing La with 0.0074 grams of sodium metaaluminate, 0.27 grams of NaOH, 1.04 grams of tetrapropylammonium bromide and 10 ml of water. After crystallization in the system for 48 hours, the crystallized product obtained becomes MFI zeolite containing rare earth after washing, separation, drying and roasting. Its XRD spectrum is as follows: figure 1 As shown, the La in the zeolite 2 o 3 The content is 24.5%.

Embodiment 2

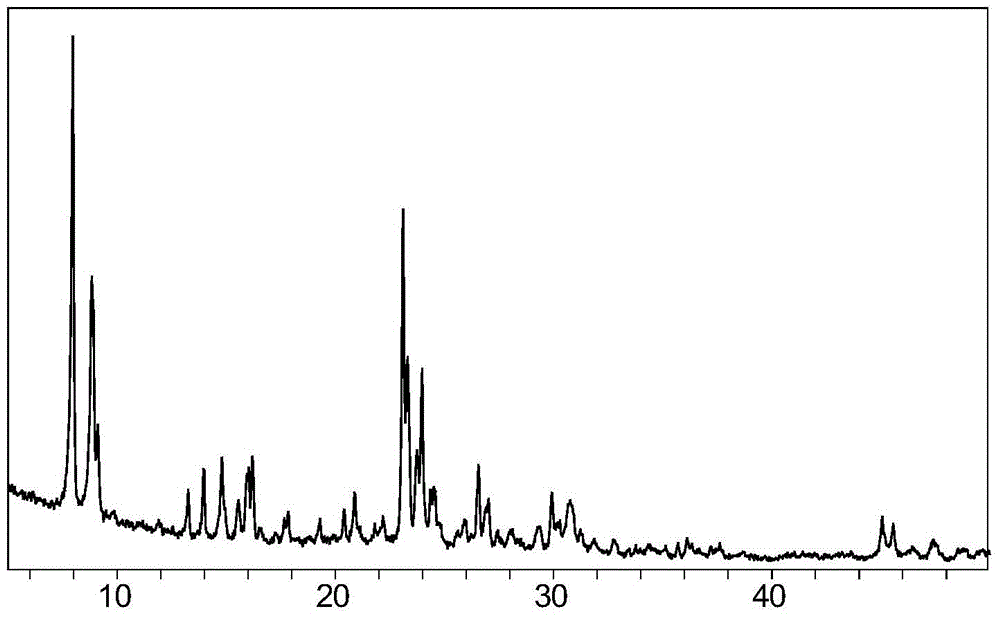

[0032] 2 grams of Magadiite with a silicon-aluminum ratio of 200 (molar ratio) are mixed with 30 milliliters of 1mol / L La(NO 3 ) 3 solution, the mixture is stirred at room temperature for 18 hours, then washed, separated and dried to obtain a mixture containing La Magadiite material.

[0033] Mix 1.8 grams of the above-mentioned Magadiite material containing La with 0.0074 grams of sodium metaaluminate, 0.27 grams of NaOH, 1.04 grams of tetrapropylammonium bromide and 10 ml of water. After crystallization in the system for 96 hours, the obtained crystallized product becomes a rare earth-containing MFI zeolite after washing, separation, drying and roasting, and the La in the zeolite 2 o 3 The content is 22.8%.

Embodiment 3

[0035] 2 grams of Magadiite with a silicon-aluminum ratio of 200 (molar ratio) are mixed with 30 milliliters of 1mol / L La(NO 3 ) 3 solution, the mixture is stirred at room temperature for 18 hours, then washed, separated and dried to obtain a mixture containing La Magadiite material.

[0036] 1.8 grams of the above-mentioned Magadiite material containing La were uniformly mixed with 0.23 grams of NaOH, 1.04 grams of tetrapropylammonium bromide and 10 ml of water, and the resulting mixture was crystallized in a closed system at a temperature of 170 ° C for 48 hours to obtain After washing, separating, drying and roasting, the crystallized product becomes the rare earth-containing MFI zeolite, and the La in the zeolite 2 o 3 The content is 23.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com