Vacuum packaging machine

A vacuum packaging machine, vacuum chamber technology, applied in packaging, packaging under vacuum/special atmosphere, transportation packaging, etc., can solve the problems of inability to meet the requirements of vacuum packaging, poor sealing effect of vacuum chambers, and inability to guarantee product quality, and achieve easy Airtight, improved packaging efficiency, easy rinse-off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention is described in detail:

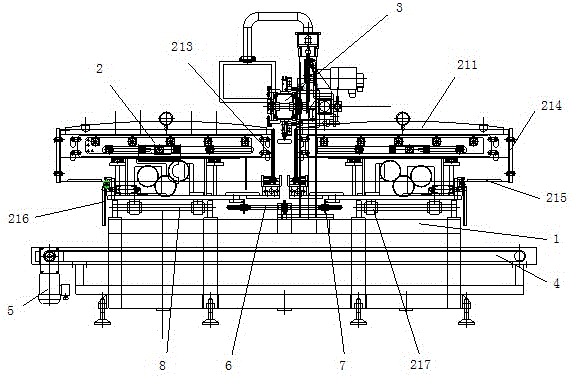

[0027] like figure 1 As shown, a vacuum packaging machine of the present invention includes a body 1 , a vacuum chamber device 2 and a feeding device 3 . There are two vacuum chamber devices 2 , which are distributed on both sides of the feeding device 3 . When working, the feeding device first feeds the vacuum chamber device on one side. After the packaging bag of the vacuum chamber device on one side is full, the vacuum chamber device on the side starts to vacuum and seal, and the feeding device feeds the vacuum chamber device on the other side. Room device feeding. The two vacuum chambers are alternately used for feeding, vacuuming and sealing, thus achieving a substantial improvement in packaging efficiency.

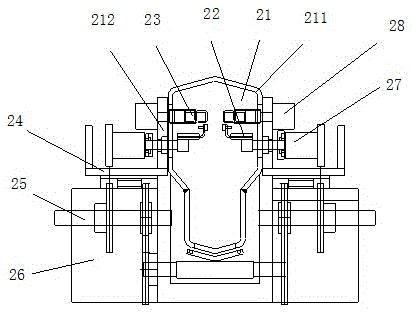

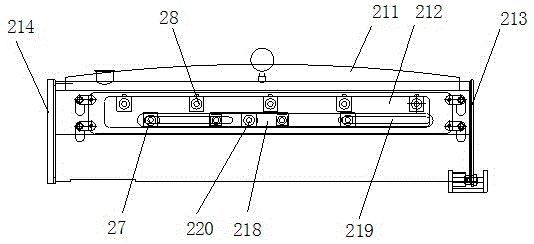

[0028] The structure of the vacuum chamber device 2 is as follows figure 2 , image 3 As shown, it includes a vacuum chamber 21 , a sealing chuck 22 , a seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com