Segmented shear type elastic wheel for rail transit vehicles

A technology for rail transit vehicles and elastic wheels, which is applied in the field of segmented shear elastic wheels, can solve problems such as the inability to realize common use of vibration damping elements, increase the development and manufacturing costs of wheels, etc., and achieve excellent vibration and noise reduction performance, The structure is simple and reasonable, and the effect of reducing the unsprung mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

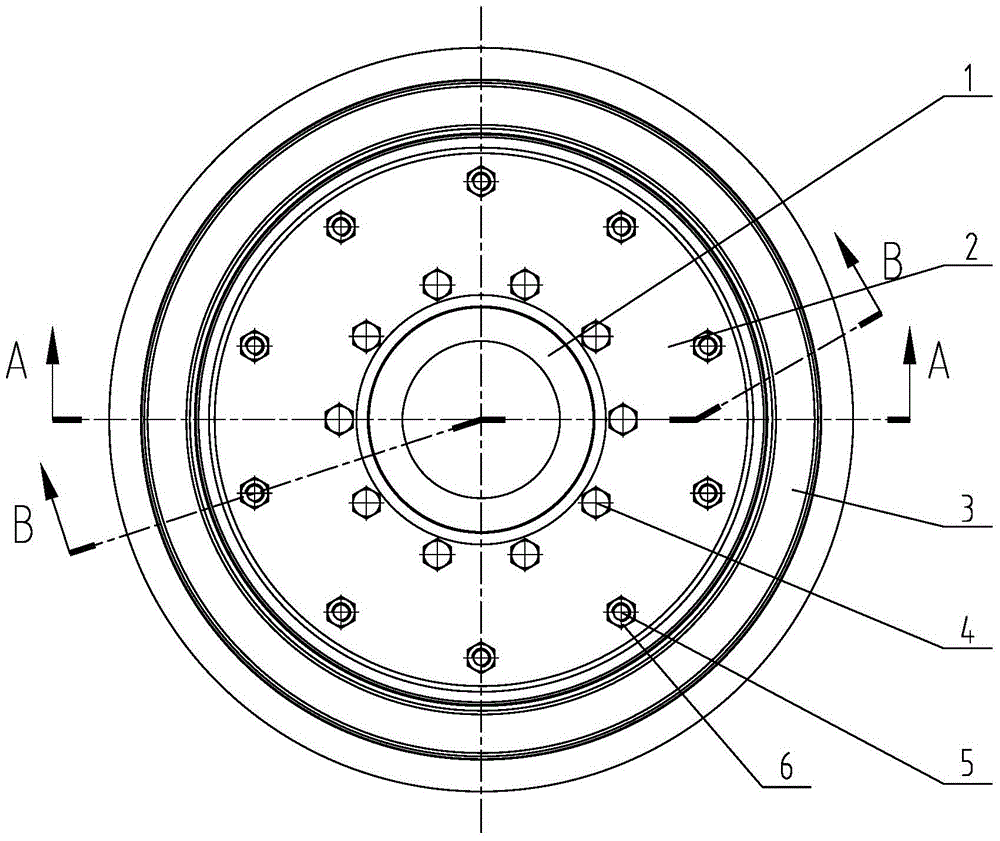

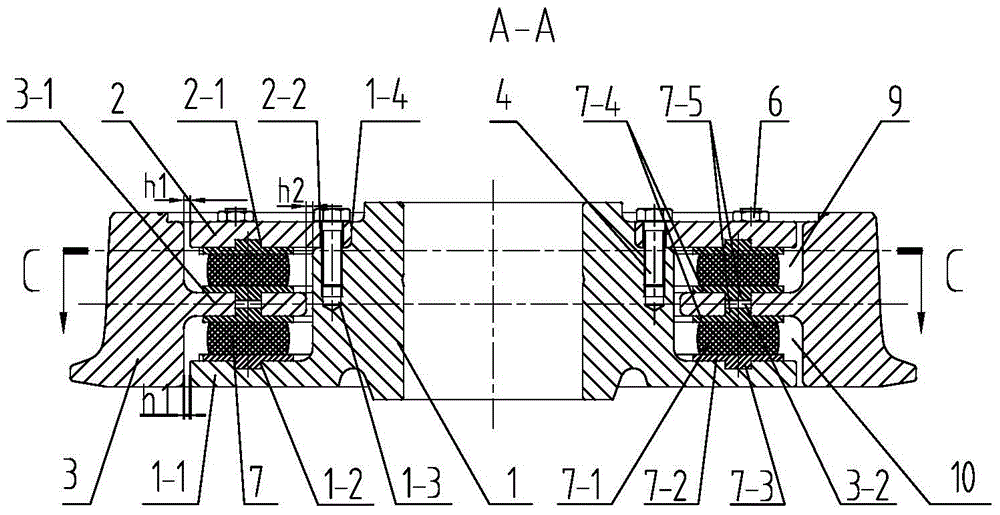

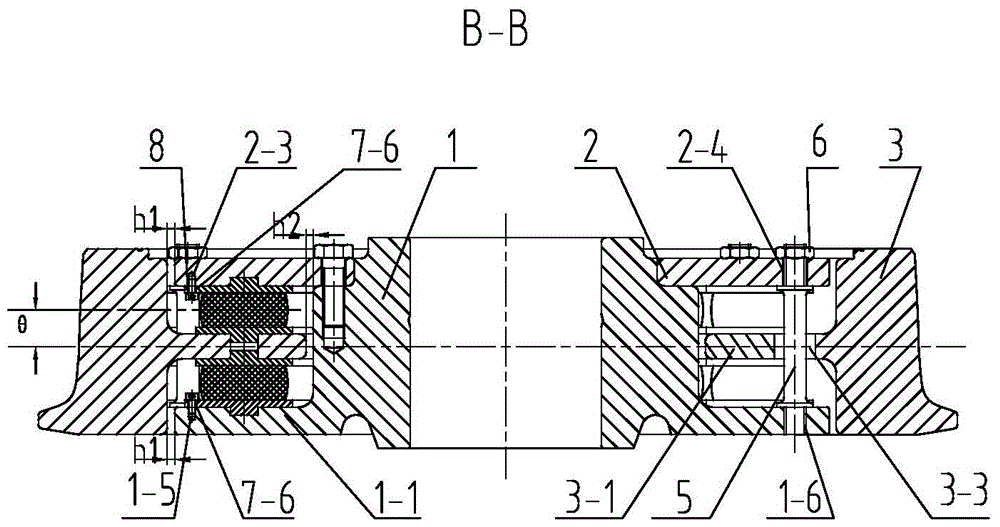

[0029] See Figure 1-7 As shown, the segmented shear type elastic wheel for rail transit vehicles of the present invention includes a wheel center 1, an annular pressure ring 2 and a tire 3 and is connected between the wheel center 1, the pressure ring 2 and the tire 3 of elastic body.

[0030] See Figure 1~4 As shown, the inner side of the wheel center 1 of the present invention has a wing plate 1-1, and the outer side has a mounting groove 1-4, and the pressure ring 2 is arranged at the mounting groove 1-4 of the wheel center 1 and is fixedly connected to the wheel center 1 by fasteners. ,See figure 2 , 3 As shown, the wheel center 1 of the present invention has an L-shaped structure along the cross-section of the center of rotation, and the end faces and outer circles of the mounting grooves 1-4 on the wheel center 1 are matched with the end faces and inner rings of the pressure ring 2, and are used to mount the pressure ring 2 Installed at the installation groove 1-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com