Printing head and three-dimensional printer

A technology of 3D printers and print heads, applied in the direction of additive processing, etc., can solve the problems of large temperature difference, easy deformation, retraction, and overflow of fuses, and achieve the effects of ensuring molding effects, improving printing accuracy, and avoiding adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

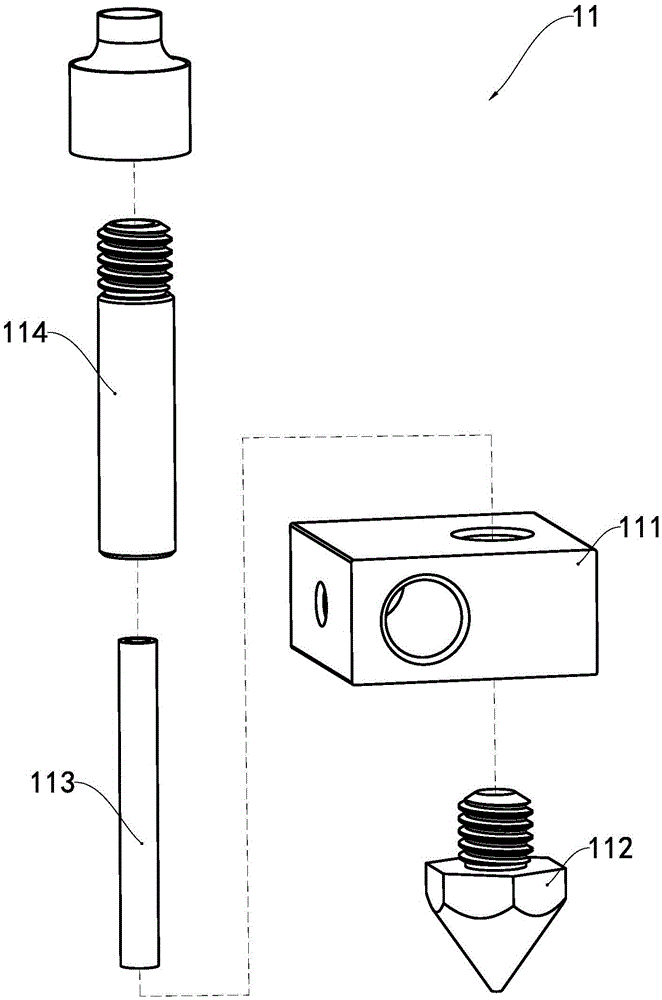

[0035] see image 3 and Figure 4 , the print head 11 of the present embodiment comprises a heating block 111, a throat 114 and a nozzle 112 fixedly connected to the heating block 111, and a Teflon tube 113 coaxially arranged with the throat 114 and being located in the throat 114, and the nozzle 112 The melting pipe 1122 is set as an outwardly expanding conical hole 1121 near the spout 1123. The conical hole 1121 is a turning space formed by the rotation of a straight line around the axis, and the closer the position to the spout 1123 is, the smaller the radius of the conical hole 1121 is. big.

[0036] see Figure 5 and Image 6 , the section near the nozzle of the print head in this embodiment is set as a tapered hole 1121, which expands outward near the nozzle 1123. After the molding material is extruded from the nozzle 1123, due to the low temperature of the external environment, the fuse is subjected to internal stress F after being cooled. The effect of deformation ...

no. 2 example

[0039] As an explanation of the second embodiment of the print head of the present invention, only the differences from the above first embodiment of the print head will be described below.

[0040] Such as Figure 7 As shown in (a) and 7(b), the expansion hole of the melt tube of the nozzle near the nozzle section is a turning space formed by the rotation of a curved section around the axis, and the radius of the expansion hole is larger as it is closer to the nozzle.

no. 3 example

[0042] As an explanation of the third embodiment of the print head of the present invention, only the differences from the above first embodiment of the print head will be described below.

[0043] Such as Figure 8As shown, the expansion hole of the melt tube of the nozzle near the nozzle section is a turning space formed by the rotation of a broken line segment around the axis, and the radius of the expansion hole is larger as it is closer to the nozzle.

[0044] The first embodiment of the three-dimensional printer:

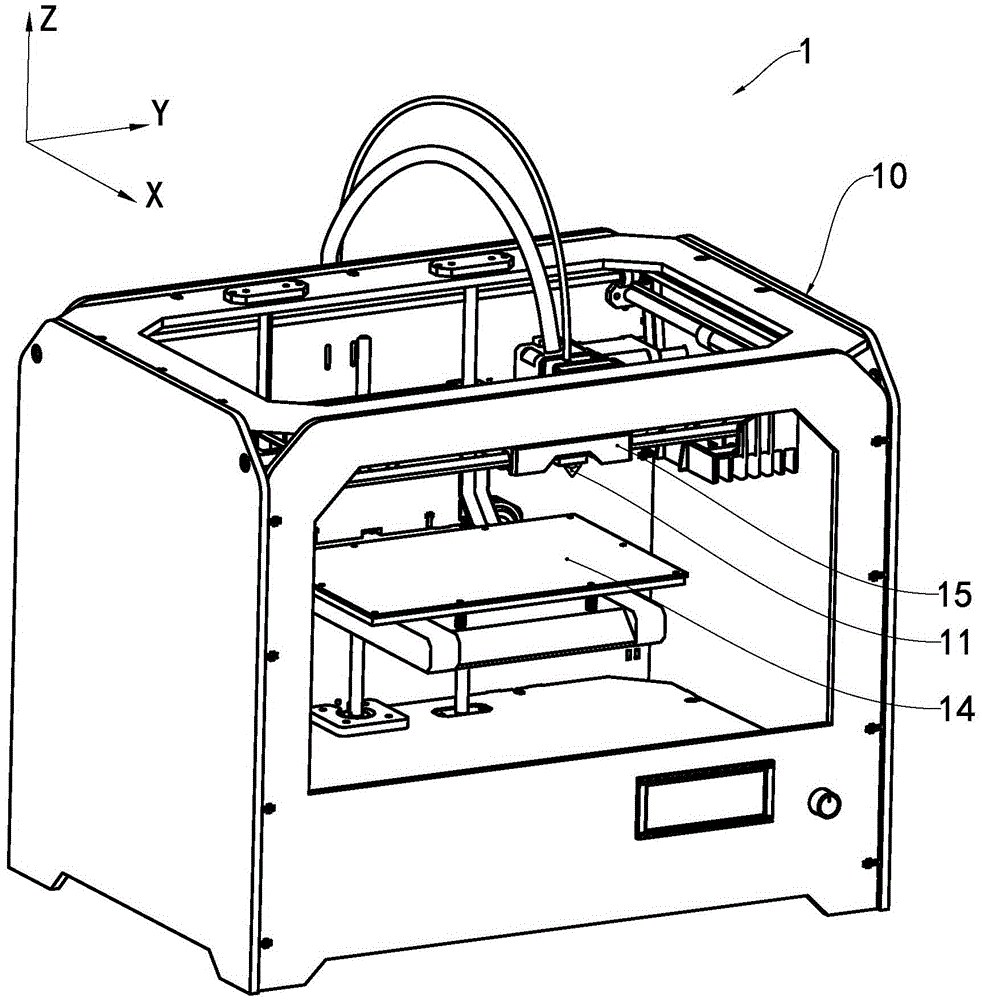

[0045] see figure 2 with Figure 4 , the three-dimensional printer 1 of this embodiment includes a frame 10 , a controller, a printing pallet 14 , and a printing head 11 arranged on a movable carriage 15 . The print head 11 prints a three-dimensional object layer by layer on the print pallet 14 according to the trajectory of the print head 11 moving relative to the print pallet 14 generated by the controller of the three-dimensional printer 1 . The print ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com