Quantitative control dressing device special for edge grinding wheel

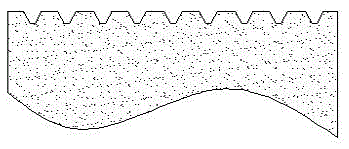

A quantitative control, grinding wheel technology, applied in abrasive surface adjustment devices, manufacturing tools, parts of grinding machine tools, etc., can solve the problem that the sharpening effect of the oil stone on the V-shaped groove of the edge grinding wheel is unstable, and the oil stone and the V-shaped groove cannot be stably controlled. The relative position of the groove and the grinding pressure, and the inability to ensure the consistency of the microscopic morphology of the V-shaped groove surface can improve the inconsistent working conditions, facilitate installation, and ensure accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

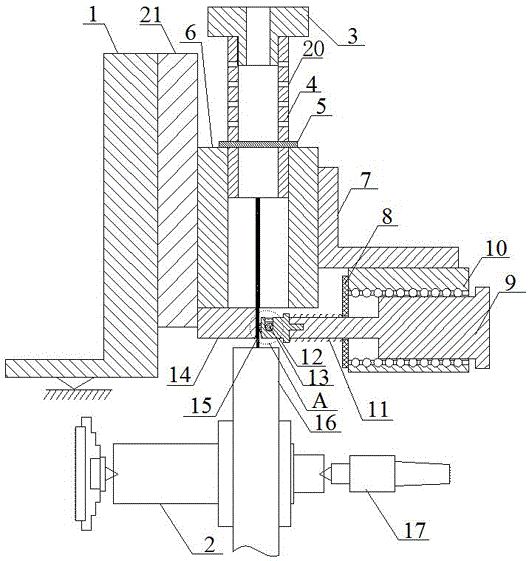

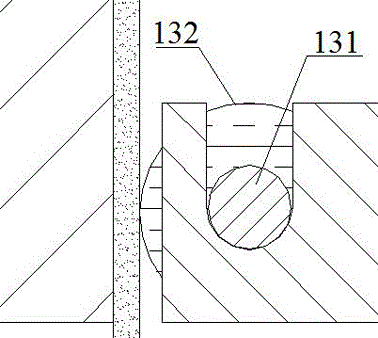

[0023] Such as Figures 2 to 5As shown, the special quantitative control sharpening device for edging and grinding wheels of the present invention includes a support 1. When in use, the support 1 is fixedly connected to the supporting plate in the lathe. The present invention also includes a fast moving mechanism, a feed mechanism and a top tightening mechanism, the fast-moving mechanism is composed of a self-locking linear slide 21, the left end of the linear slide 21 is fixedly connected with the support 1; , the guide sleeve 6 is fixedly connected with the right end of the linear slide table 21, when the linear slide table 21 moves up and down, because its right end is connected with the guide sleeve 6 of the feed mechanism, it will drive the feed mechanism to move up and down; The center of the sleeve 6 is provided with a narrow groove 18 for inserting the thin slice of oil stone 15, the width of the narrow groove 18 is adapted to the thickness of the thin slice of oil sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com