Intelligent grinding machine

A grinding machine, intelligent technology, applied in the direction of grinding machines, grinding machine parts, machine tools suitable for grinding workpiece planes, etc., can solve the problems of complex structure and slow speed of grinding machines, and achieve simplification of control difficulty, cost reduction and structure simplification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

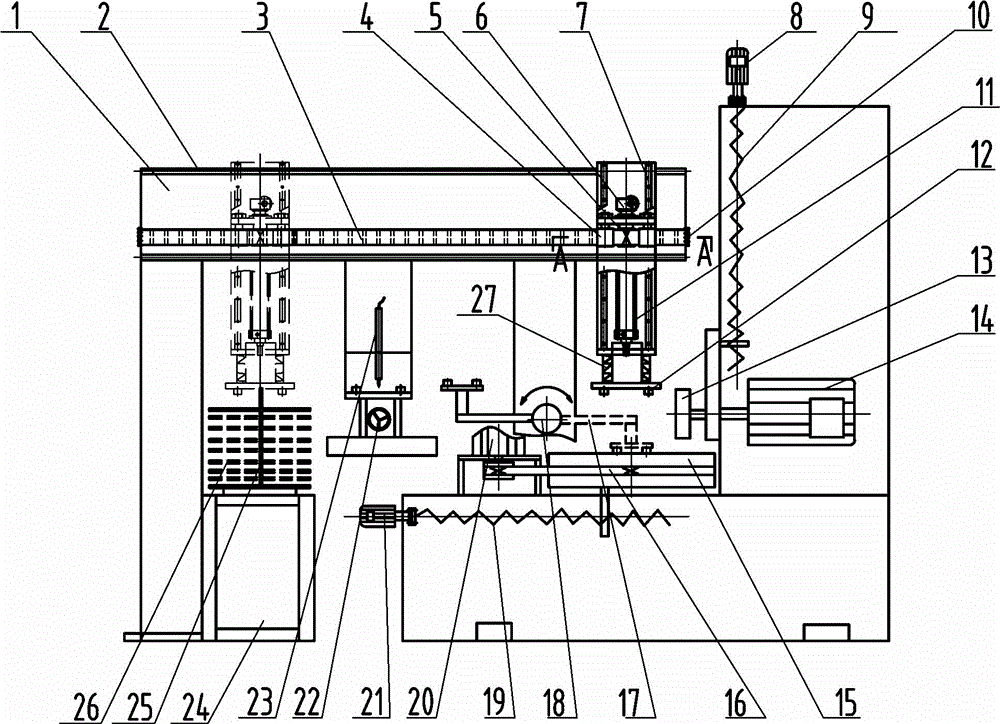

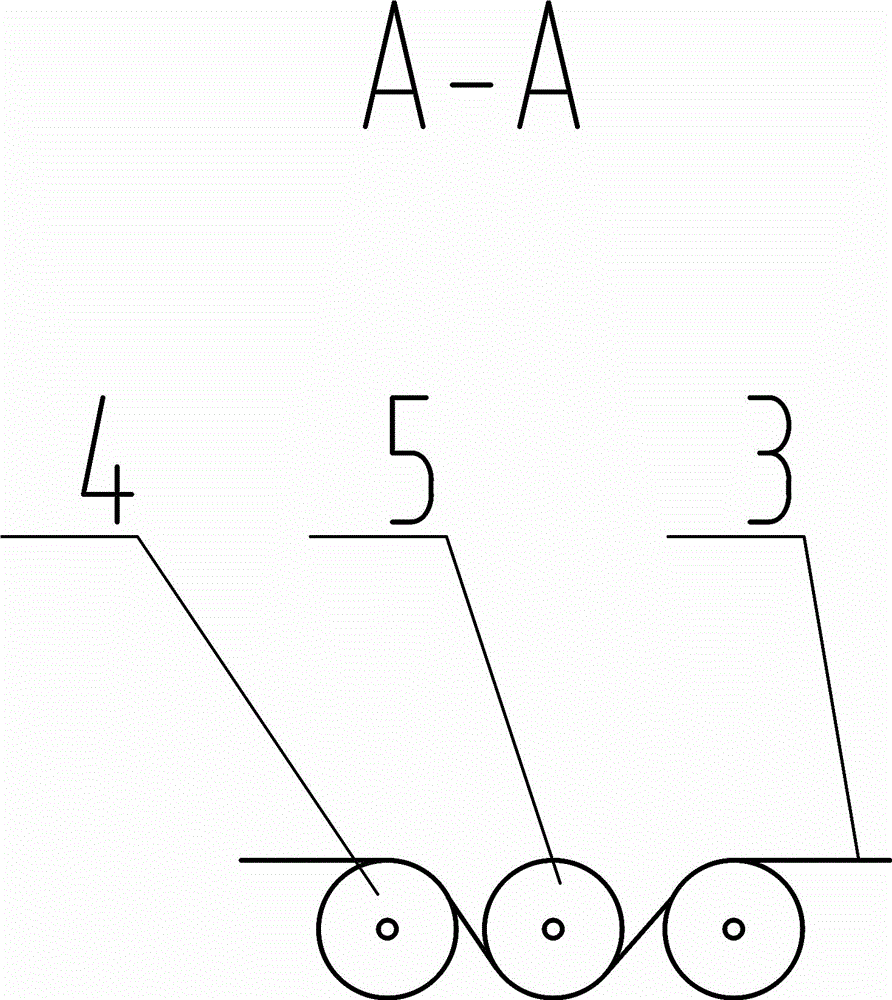

[0021] Such as figure 1 Among them, an intelligent grinding machine includes a beam 1, on which a mechanical arm that moves along a horizontal guide rail 2 is arranged, and below the beam 1, a workpiece platform 24, a thickness detection device, an overturning arm 17 and a magnetic disk 15 are sequentially arranged. A main shaft and a grinding wheel are arranged above the side, a workpiece guide rod 25 is provided on the workpiece platform 24, a lifting guide rail 7 is provided on the mechanical arm, and a cylinder 11 is installed on the mechanical arm to drive the electromagnetic chuck 12 to lift along the lifting guide rail 7. A spring 27 for buffering is provided above. The cylinder 11 is used to drive the electromagnetic chuck 12 up and down, and the spring 27 is used to buffer the electromagnetic chuck 12, so the lifting drive structure is simplified, and the cylinder only needs to act according to the lifting signal without the height control signal. Buffered by the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com