Plastic powder coating process for anti-spotting of surfaces under wet conditions

A technology of surface spots and conditions, which is applied to the device for coating liquid on the surface, the pretreatment surface, the coating and other directions, which can solve the problems affecting the spraying effect of the workpiece, spots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

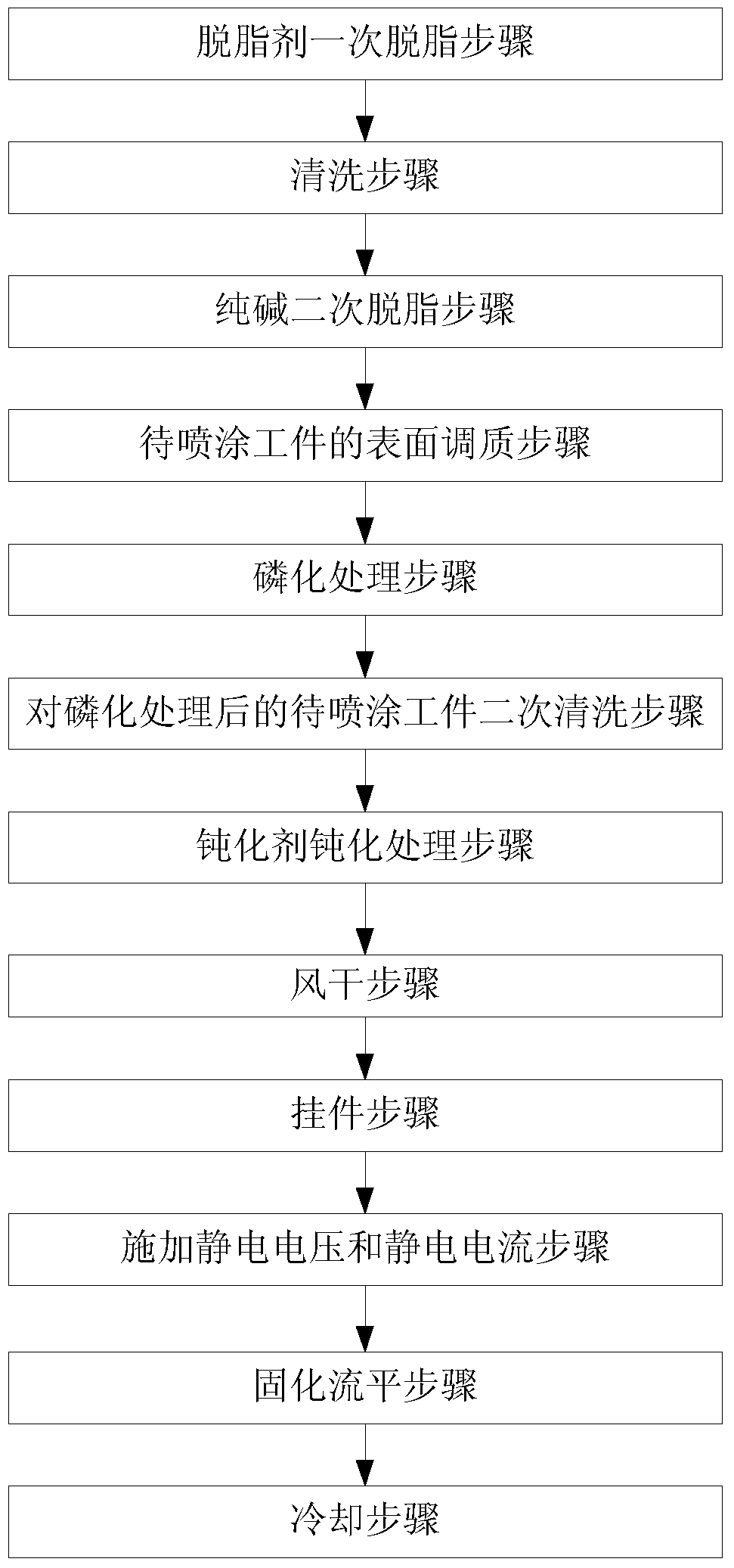

Image

Examples

Embodiment 1

[0023] (1) The first degreasing step of the degreasing agent: under the condition that the pH value is 12 and the temperature is 40°C, the workpiece to be sprayed is degreased with a degreasing agent, and the degreasing process lasts for 10 minutes; the degreasing step is used to remove the oil and impurities;

[0024] (2) Cleaning step: under the condition that the pH value is 7, utilize clear water to clean the workpiece to be sprayed after the degreasing process, and the cleaning process lasts for 3 minutes; Clean the workpiece to be sprayed to wash off the remaining degreasing agent on the workpiece to be sprayed;

[0025] (3) Secondary degreasing step of soda ash: under the condition that the pH value is 9 and the temperature is 20°C, use soda ash to degrease the cleaned workpiece to be sprayed, and the degreasing process lasts for 3 minutes;

[0026] (4) The surface conditioning step of the workpiece to be sprayed: under the conditions of pH value 8 and temperature 20°C...

Embodiment 2

[0039] (1) One-time degreasing step of degreasing agent: under the condition of pH value of 13 and temperature of 45°C, the workpiece to be sprayed is degreased with a degreasing agent, and the degreasing process lasts for 12.5 minutes; oil and impurities;

[0040] (2) Cleaning step: under the condition that the pH value is 7.5, utilize clear water to clean the workpiece to be sprayed after the degreasing process, and the cleaning process lasts for 4 minutes; Clean the workpiece to be sprayed to wash off the remaining degreasing agent on the workpiece to be sprayed;

[0041] (3) Secondary degreasing step of soda ash: under the condition of pH value of 9.5 and temperature of 25°C, use soda ash to degrease the cleaned workpiece to be sprayed, and the degreasing process lasts for 4 minutes;

[0042] (4) The surface conditioning step of the workpiece to be sprayed: under the conditions of pH value 8.5 and temperature 25°C, the surface of the workpiece to be sprayed is treated wit...

Embodiment 3

[0055] (1) The first degreasing step of the degreasing agent: under the condition that the pH value is 14 and the temperature is 50°C, the workpiece to be sprayed is degreased with a degreasing agent, and the degreasing process lasts for 15 minutes; the degreasing step is used to remove the oil and impurities;

[0056] (2) Cleaning step: under the condition that the pH value is 8, utilize clear water to clean the workpiece to be sprayed after the degreasing process, and the cleaning process lasts for 5 minutes; Clean the workpiece to be sprayed to wash off the remaining degreasing agent on the workpiece to be sprayed;

[0057] (3) Secondary degreasing step of soda ash: under the condition that the pH value is 10 and the temperature is 30° C., use soda ash to degrease the cleaned workpiece to be sprayed, and the degreasing process lasts for 5 minutes;

[0058] (4) Surface conditioning step of the workpiece to be sprayed: under the conditions of pH value 9 and temperature 30°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com