A fully automatic roll-to-roll terminal feeding mechanism

A feeding mechanism and fully automatic technology, applied in the manufacture of printed circuits, electrical components, printed circuits, etc., can solve the problems of manual operation, low production efficiency, time-consuming processing, etc. The effect of high efficiency and product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and preferred embodiment of the present invention, the present invention will be further described:

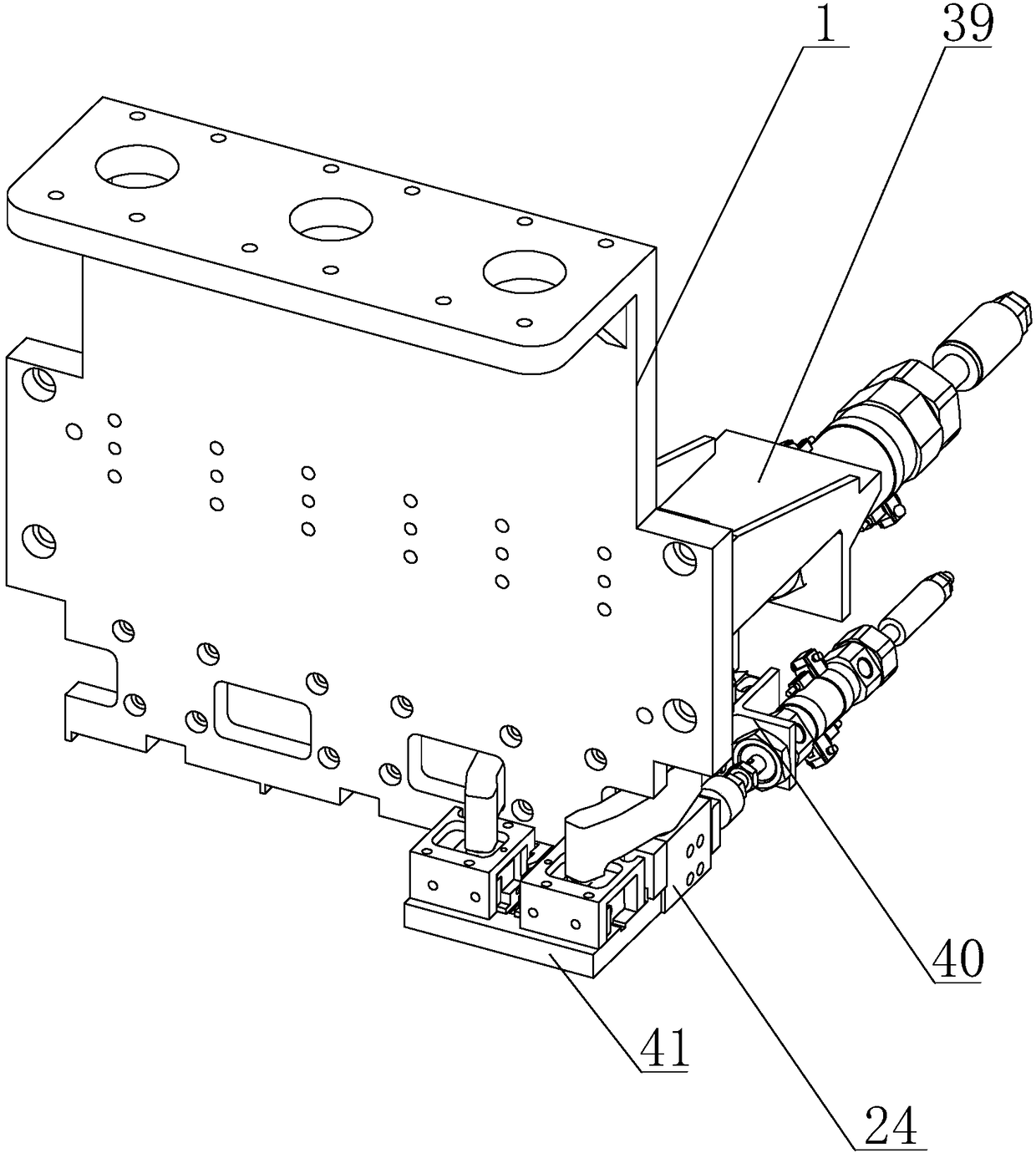

[0019] refer to figure 1 and figure 2 , a fully automatic package terminal feeding mechanism of the present invention is characterized in that it includes a mounting base 1, a cutter assembly 41, a feeding assembly 40 and a power assembly 39 are fixed on the mounting base 1, and the cutter assembly 41 is set At the lower end of the mounting base 1 , the feeding assembly 40 is connected to the cutter assembly 41 and is provided with a connecting rod assembly driven by a power assembly 39 , and the power assembly 39 is connected to the mounting base 1 and is disposed above the cutter assembly 41 .

[0020] The feeding assembly 40 includes a base 24 fixed on the mounting seat 1, a beak bracket 20 fixed on the base 24, a beak assembly hinged with the beak bracket 20, and clamped on the The second slide rail assembly 8 at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com